Quality Control - Gateway Engineering Education Coalition

TOTAL QUALITY

MANAGEMENT

(Continuous Quality

Improvement)

QUALITY PLANNING

Who is customer?

What do they need?

QUALITY CONTROL

Evaluate, compare, act

QUALITY

IMPROVEMENT

Establish infrastructure

Who is customer?

What Level of Quality do they need?

Are they purchasing to Some Quality Specification?

Any Safety Considerations?

Future Litigation?

Ethical Issues?

QUALITY PLANNING

Who is customer?

What do they need?

QUALITY CONTROL

Evaluate, compare, act

QUALITY

IMPROVEMENT

Establish infrastructure

QUALITY CONTROL

Inspection

Destructive

Non-destructive

Sampling

Process Control

Monitoring Process (relates to inspection)

Feedback Control

Statistical Process Control (knowing when the process is out of control)

Correction

Knowing what to correct when process is out of control

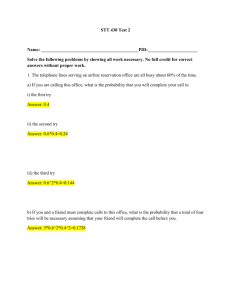

Cost of Quality Before & After

Improvement

80

70

60

50

40

30

20

10

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

Time

Series

1

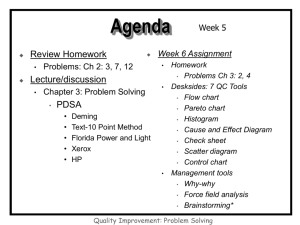

Tools for Quality

Control

Check Sheets

Pareto Charts

Why-Why Diagrams

Cause & Effect Diagrams

Flowcharts

Histograms

Scatter Diagram

Control Charts

Problem

Solving

Steps

Plan

Do

Study

Act

Link these

Two in

Quality

Circle

CHECK SHEETS

Used to keep a record of the number and type of discontinuities over a specified period of time or within a certain batch of product.

PARETO CHART

A graphical representation ranking discontinuities from the most to least significant. Used to help brainstorm what discontinuities, if worked upon first, would be the most likely to produce the greatest improvement in quality.

Class Example

Our manufacturing procedure is composed of several steps. Several of these procedures have lead to discontinuities noticed upon inspection. The steps causing defectives are as follows:

Caulking

Fitting

Connections

Torque

Gapping

198 defectives

25 defectives

103 defectives

18 defectives

72 defective

A Pareto Diagram will be developed.

WHY-WHY DIAGRAMS

A systematic representation of causes of why some occurrence happens. Used to guide brainstorming sessions.

FLOW CHARTS

Flow charts are graphical representations of the steps involved in a process. Constructing a flow chart helps give a better understanding of the systems involved.

Process

Data Decision

Y es

Process

No

Process

Control transfer

Terminator

CAUSE AND EFFECT DIAGRAMS

(Fishbone Diagram)

Used in brainstorming session to help identify the causes of quality losses. This diagram is particularly useful after the flow chart and the Pareto diagrams have been developed.

Cause

QUALITY

(Effect)

Step 1:Decide on the quality characteristic {e.g. Reduction of wobble during machine rotation}

Step 2:Set up the fish bone backbone

Step 3:Identify main factors causing effect {e.g. Workers,

Materials, Inspection, Tools}

Step 4: Add Cause to each branch

Benefits of Cause and Effect Diagram

Making diagram is educational in itself

Outline relationship

Note what samples need to be taken

Guide for discussion

Causes are actively sought and results written on diagram

Appropriate data collected - no time wasted

Shows level of technology

Problem

Solving

Steps

Plan

Do

Study

Act

Link these

Two in

Quality

Circle

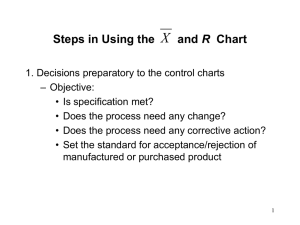

CONTROL CHARTS

Used to test if the process is in control

Used to see if significant changes have occurred in the process over time

“Indiscreet” or

“Continuous Data

Chart” or “X-R Chart”

Measurement at time intervals

Measurements compared control over time.

Examples:

“Discrete Data Charts” or

“pn-p charts”

Inspection on lot or batch

Note # good/defective

# of parts inspected in the lot = n

Fraction of defective in lot = p

Number of defectives = pn

Length (mm) Volume (cc)

Weight (gm) Power (kwh)

Time (sec) Pressure (psi)

Voltage (v)

X

- R CHART CONSTRUCTION

Class Example

In the manufacturing process for this example parts are being machined with a nominal diameter of 13 mm. Samples are taken at the following times of day: 6:00, 10:00, 14:00, 18:00 and 22:00, for 25 consecutive days. The diameter measurements from these samples are presented on the table in the next slide.

Step 1: Collect Data

Step 2: Sort data into subgroups (i.e. lots, order #, days, etc.) n = size of the subgroup {in this example 5 times per day) k = number of subgroups {in this example 25 days}

Step 3: Find the mean for each subgroup ( X )

X =

X

1

X

2

X

3

.....

n

X n

Step 4: Find Range for each subgroup ( R )

R = X largest value

- X smallest value

Step 5: Find Overall Mean ( X )

X =

X

1

X

2

X

3

...

X k k

Step 6: Find average value of range ( R ) R =

R

1

R

2

R

3

...

R k k

Step 7: Complete control limits using attached table

For X Control Chart

Central Line - CL =

Upper Control Limit - UCL = +A

2

R

Lower Control Limit - LCR = - A

2

R

For R Control Chart

Central Line - CL = R

Upper Control Limit - UCL = D

4

R

Lower Control Limit - LCR = D

3

R

Step 8:Plot Chart

P CONTROL CHART CONSTRUCTION

Class Example

An inspector at the end of the manufacturing line for the production of car wheel rims, at the end of each shift, inspects the lot of wheel rims made during that shift. On good days when the welder is running properly, over 400 wheels are made per batch. On poor days, as low as 50 to 60 wheels are made per batch. The inspector marks on his/her

“check sheet” for each batch the total number of wheels inspected and the number of defects returned for rework in each lot.

Step 1: Collect Data

Step 2: Divide data into subgroups (usually days or lot). Subgroup size should be greater than 50 units. n = number in each subgroup pn = number of defects in each subgroup

Step 3: Compute fraction of defectives (for %, multiply by 100) p = pn/n

Step 4: Find the Average Fraction of Defectives ( ) p =

(

(

=

pn n

Step 5: Compute the Control Limits for each Lot

Central Line CL =

Upper Control Limit UCL = + 3

- 3 p ( 1

p ) n p ( 1

p ) n

Step 6:Draw P Control Chart

PN CONTROL CHART CONSTRUCTION

Class Example

On an assembly line of windshield wiper motors, the inspector selects randomly 100 motors per hour to examine. The inspector notes on the

“check sheet” the number of defective motors in each 100 selected.

Step 1: Collect Data (lot size set constant)

Step 2: Calculate Values p =

pn n n n + 3 pn ( 1

p ) n - 3 pn ( 1

p )

Step 3: Plot Chart

QUALITY PLANNING

Who is customer?

What do they need?

ISO

9000

QUALITY CONTROL

Evaluate, compare, act

QUALITY

IMPROVEMENT

Establish infrastructure