History and Current Status of the Plastics Industry

advertisement

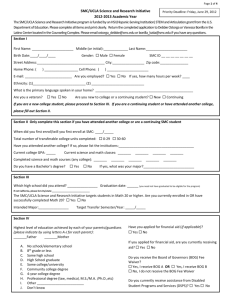

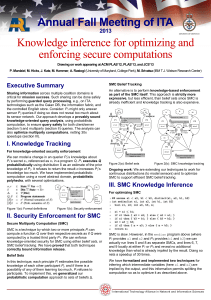

SMC, RRIM, GMT Manufacturing Costs Professor Joe Greene CSU, CHICO Copyright Joseph Greene 2004 1 Objectives • • • • • • Part Costs Review SMC Bumper Costs GMT Bumper Costs SMC Fender Costs RRIM Fender Costs Plastic Fender Costs Copyright Joseph Greene 2004 2 Compression Molding Costs • Many methods are used to determine the cost of compression molded part – rough estimates based upon rules of thumb or experience – extremely detailed analysis based on costs for numerous plant functions – spreadsheet based analysis, IBIS and Associates • Costs are broken into the following areas – Material costs including additives – Part costs including scrap rate – Tooling costs – Machine costs including labor rate – Secondary operations costs for trimming, sanding, painting, bonding – Purchased items costs including fasteners, inserts, and others – Packaging and shipping costs – Overhead costs from company – Marketing and profit Copyright Joseph Greene 2004 3 Compression Molding Costs • Part 1: Resins and Additives Costs – – – – Type and grade of material, e.g., bumper beam is SMC (stuctural) Cost of material depending upon quantity, e.g., pounds per year required Additives cost, e.g., mold release, profile additives. Total Material Cost = (resin cost)*(resin fraction) + (additives cost)* (additives fraction) • Example, Total Cost = $1.50 * 10 (SMC pounds) + $3.00 * 0.5 (additives pounds) per part = $16.50 per part • Part 2: Part Costs – Part costs = material costs plus factory costs – Material cost is materials plus scrap from trim and part rejects. • Example: bumper weighs 10.5 pounds. The edge trim and mounting holes scrap is 1%. Scrap rate for parts is 9% Total material uses is 10.5*(0.1) = 1.2 pounds • Scrap Cost = $1.5 * 1.2 = $1.8 per part Copyright Joseph Greene 2004 4 Compression Molding Costs • Part 3: Tooling Costs – Type of tooling material, e.g. steel, aluminum, kirksite. – Complexity of tool – Number of slides or lifters in a tool to mold parts that have an internal flange or under cut. – Number of years the tool is amortized for tool life, e.g., payoff tool in 1 year, 3 years, or five years. (Every company has different accounting practices. – Internal (In-House) tool construction versus External (Outside) tool construction. Internal is usually less expensive per tool but has more overhead, thus need many jobs to reduce overhead costs. – Chrome plating or not. Chrome plate last about 100,000 cycles. – Number of years tooling is amortized. GM amortized in 1 year. – Example, bumper beam with 150,000 parts per year for 4 years. • $300,000 per tool • Cost per part is $300,000/ 150,000parts = $ 2 per part – Comparison steel stamping bumper beam costs $1.5 million • Per part cost is 1,500,000/150,000 = $10 per part Copyright Joseph Greene 2004 5 Compression Molding Costs • Part 4: Machine Costs – Cost of machine is dependent upon the time the machine is in use to make parts and whether the machine has an operator or not. – The number of machines required to keep up with production demand of 150,000 – Rates are determined from • Original cost of machine • Ongoing operations costs • Special equipment costs for particular jobs, e.g., special controllers or chillers • Cycle time • Example, bumper beam – Cycle time is 60 seconds yields 60 parts per hour, 480 parts per shift, 480 parts per day (for 1 shift), 2400 parts per week, 115,200 parts per year (for 48 weeks). Can ramp up to 1.5 shifts to reach 172,000 parts per year. – Hourly rate is $20 for operator – Machine rates are $60 per hour – Bumper example – Cost = $60 per hour / 60 parts per hour = $1 per part Copyright Joseph Greene 2004 6 Compression Molding Costs • Part 5: Secondary Operations Costs – Many parts are subject to other operations costs after molding • placed or glued into an assembly, drilling of holes or attachments – Rates are determined from some rate and cycle time • Rate costs are dependent upon the type of machine used, $ per hour • Cycle time, parts per hour • Deflashing part is not considered secondary operations since the flash is removed at the press after molding. • Example, bumper – Punching out the holes for the rail mounts – Cycle time is 10 seconds yields 60 parts per hour – Cost = $10 per hour / 60 parts per hour = $0.1667 per part • Part 6: Purchase Items Costs – Many items are purchased and included in assembly • Example, bumper has the bolts and metal bracket piece for the rails – Cost of bolts = $0.1 x 4 = $0.40 per part – Cost of metal bracket = $0.1 x 1 = $0.10 per part Copyright Joseph Greene 2004 7 Compression Molding Costs • Part 7: Packaging and Shipping Costs – Costs for shipping cartons, bags, blister packages, foam materials – Costs for transportation can be included • Example, bumper – Costs for bumper = $50 per 100 parts – Cost of cardboard box = $1 per box that holds 100 parts • • • • Total Factory Costs per part = $22.08 General Administration Costs = 10% = $2.208 Marketing and Profit = 20% = $4.42 Total Cost per part =$28.68 per bumper for SMC and weighs 15 pounds (for Corvette) • Comparison versus Steel bumper – Piece cost: $18 steel versus $28 for SMC ... Net loss of ($10) per part – Weight: 25 pounds (steel) versus 15 pounds (SMC)…Net savings 15 pounds – Tooling cost: $1.5M steel versus $300,000 (SMC) … Net savings $1.2 Million Copyright Joseph Greene 2004 8 Part Costs- Example • Bumper beam for Chevy Camaro-Firebird • Given – Volume is 150,000 cars per year – Car weight is 3750 pounds curb weight (with 4 occupants and luggage) – Current production Steel beam • Weight is 18 pounds and costs $14 for in-house manufacturing • Tooling costs for steel beam is $1.5 million or $10 per part for amortized • Total costs for steel beam is $24 per part – Performance required • • • • • • 5 mph pendulum impact between 15” to 21” from the ground 2.5 mph pendulum impact between 15” to 21” from the ground on the corner 5 mph barrier impact at room temperature and at –20°C Bumper must survive two pendulum impacts and a barrier impact and not break. System deflection must be less than 4 inches and a bumper deflection of less than 1 inch Static test loading of 9,000 pounds at 1 inch deflection. – Mass reduction is desired – Composite material options • SMC versus GMT • What are the costs assuming equal performance Copyright Joseph Greene 2004 9 Static Test Setup with a Pendulum Face Moving at a Constant Speed into a Rigidly Mounted Beam constant speed Pendulum Face F Bumper Beam a. Cross Car Pendulum Face Bumper Beam b. Cross Section Copyright Joseph Greene 2004 10 SMC Bumper Beam Costs- Example • Part costs are quoted from suppliers. – The suppliers typically design the bumper beam with their material – The suppliers then quote a part price based upon part weight and volume per year. • Costs are broken into the following areas – Material costs • SMC is $1.50 per pound for structural SMC from Ashland Chemical Company. • Part weight in SMC is 12 pounds (Density of structural SMC is 2.0 g/cc) and Part thickness is 0.250 inches. • Material part cost is $18 per part. – Part costs including scrap rate • SMC scrap rate is 10% • Scrap rate cost is $1.80 per part. – Tooling costs • SMC tooling costs for bumper beam is $300,000 for 500,000 parts total. • Amortized tooling costs in 1 year for 150,000 parts. • Tooling part cost is $300,000/150,000 parts = $2 per part Copyright Joseph Greene 2004 11 SMC Bumper Beam Costs- Example • Costs (Continued) – Machine costs including labor rate (Cold SMC is heated in mold) • Machine costs for compression press are $60 per hour. • SMC cycle time is 2 minutes per part or 30 parts per hour. • Machine part costs are $60/30 parts per hour = $2 per part. – Secondary operations costs for trimming and punching holes • Secondary rates are $12 per hour • Secondary cycle time is 60 seconds per part or 60 parts per hour. • Secondary part costs are $12/60 parts per hour = $0.20 per part – Total manufacturing costs of SMC bumper is sum of all above costs. • $18 + $1.80 + $2 + $2 + $0.20 = $24 compared with $14 per part for steel beam. Cost is $10 per bumper beam or $1.5 million per year (150K parts) – Weight savings is 18 pounds for steel – 12 pounds SMC = 6 pounds. Copyright Joseph Greene 2004 12 SMC Bumper Beam Costs- Example • Costs (Continued). These are similar for steel and SMC – Purchased items costs including mounting bolts and foam pad for energy absorber. • Mounting bolts and bracket = $1 per assembly in a part • Foam pad weighs 2 pounds and costs $2 per pound = $4 per part – Packaging and shipping costs- typically by weight and ability to stack parts. Bumpers stack very well. • Packaging and shipping costs are $0.50 per part – Overhead costs from company- typically 10% of manufactured costs • Overhead costs = 0.10 x $24 = $2.40 – Marketing and profit- typically 10-20% of manufactured costs • Profit costs = 0.20 x $24 = $4.80 – Total costs • $24 + $4 + $0.50 + $2.40 + $4.80 = $35.70 per part for 150,000 parts per year or $5.355 million per year • Some suppliers may not provide hardware or foam pad and may not charge for overhead or profit and instead try and get a cheaper price on the SMC material and reduce cycle time and scrap rate. – Cost of weight savings is $11.70/6 pounds = $1.95 per pound saved Copyright Joseph Greene 2004 13 GMT Bumper Beam Costs- Example • Part costs are quoted from suppliers. – The suppliers typically design the bumper beam with their material – The suppliers then quote a part price based upon part weight and volume per year. • Costs are broken into the following areas – Material costs (less than SMC) • GMT is $1.5 per pound for GMT from General Electric. • Part weight in GMT is 10 pounds (Density of structural GMT is 1.19 g/cc) and Part thickness is 0.300 inches. • Material part cost is $15 per part. – Part costs including scrap rate (less than SMC) • GMT scrap rate is 5% • Scrap rate cost is $0.75 per part. – Tooling costs (same as SMC) • GMT tooling costs for bumper beam is $300,000 for 500,000 parts total. • Amortized tooling costs in 1 year for 150,000 parts. • Tooling part cost is $300,000/150,000 parts = $2 per part Copyright Joseph Greene 2004 14 SMC Bumper Beam Costs- Example • Costs (Continued) – Machine costs including labor rate (Hot GMT is cooled in mold) • Machine costs for compression press are $60 per hour. • GMT cycle time is 2 minutes per part or 30 parts per hour. • Machine part costs are $60/30 parts per hour = $2 per part. – Secondary operations costs for trimming and punching holes • Secondary rates are $12 per hour • Secondary cycle time is 30 seconds per part or 120 parts per hour. • Secondary part costs are $12/120 parts per hour = $0.10 per part – Total manufacturing costs of GMT bumper is sum of all above costs. • $15 + $0.75 + $2 + $2 + $0.10 = $19.85 compared with $14 per part for steel beam. Cost is $5.85 per bumper beam or $0.8775 million per year (150K parts) – Weight savings is 18 pounds for steel – 10 pounds SMC = 8 pounds. Copyright Joseph Greene 2004 15 SMC Bumper Beam Costs- Example • Costs (Continued). These are similar for steel and GMT – Purchased items costs including mounting bolts and foam pad for energy absorber. • Mounting bolts and bracket = $1 per assembly in a part • Foam pad weighs 2 pounds and costs $2 per pound = $4 per part – Packaging and shipping costs- typically by weight and ability to stack parts. Bumpers stack very well. • Packaging and shipping costs are $0.50 per part – Overhead costs from company- typically 10% of manufactured costs • Overhead costs = 0.10 x $24 = $2.40 – Marketing and profit- typically 10-20% of manufactured costs • Profit costs = 0.20 x $24 = $4.80 – Total costs • $19.85+ $4 + $0.50 + $2.40 + $4.80 = $31.55 per part for 150,000 parts per year or $4.733 million per year • Some suppliers may not provide hardware or foam pad and may not charge for overhead or profit and instead try and get a cheaper price on the GMT material and reduce cycle time and scrap rate. – Cost of weight savings is $7.55/8 pounds = $0.94 per pound saved Copyright Joseph Greene 2004 16 Part Costs- Fender Example • Composite Fender for Corvette • Given – Volume is 30,000 cars per year – Car weight is 3,750 pounds curb weight (with 4 occupants and luggage) – Steel fender comparison • Weight is 6 pounds and costs $10 for in-house manufacturing (40% off-all scrap) • Tooling costs for steel fender is $1 million or $33 per part for amortized • Total costs for fender is $43 per part – Performance required • • • • Dimensional accurate Minimum warping Gloss level and Distinctness of Image (DOI) Offline paint-able and not elpo paint process (for steel components of 380°F) – Composite material options • SMC versus RRIM versus injection molding • What are the costs assuming equal performance Copyright Joseph Greene 2004 17 Composite or Plastic Fender • Fender is separate piece from hood • Fender can be made – SMC – RRIM urethane – Injection molded • Fender has opening for wheel and light • Fender must not appear wavy • Fender painted off line not with body. Copyright Joseph Greene 2004 18 SMC Fender Costs- Example • Part costs are quoted from suppliers. – The suppliers typically design the bumper beam with their material – The suppliers then quote a part price based upon part weight and volume per year. • Costs are broken into the following areas – Material costs • SMC is $1.50 per pound for phase epsilon (body panel) SMC from Ashland Chemical Company. • Part weight in SMC is 3 pounds (Density of SMC is 1.8 g/cc) and Part thickness is 0.125 inches. • Material part cost is $4.50 per part. – Part costs including scrap rate • SMC scrap rate is 10% • Scrap rate cost is $0.45 per part. – Tooling costs • SMC tooling costs for fender is $250,000 for 500,000 parts total. • Amortized tooling costs in 1 year for 30,000 parts. • Tooling part cost is $250,000/30,000 parts = $8.33 per part Copyright Joseph Greene 2004 19 SMC Fender Costs- Example • Costs (Continued) – Machine costs including labor rate (Cold SMC is heated in mold) • Machine costs for compression press are $60 per hour. • SMC cycle time is 1 minute per part or 60 parts per hour. • Machine part costs are $60/60 parts per hour = $1 per part. – Secondary operations costs for trimming and punching holes • • • • Secondary rates are $12 per hour Secondary cycle time is 60 seconds per part or 60 parts per hour. Secondary part costs are $12/60 parts per hour = $0.20 per part Painting costs are needed because of offline paint – Fender is supported in paint buck and then painted in group of 10 – Paint costs are for paint buck tooling, paint, cycle time = $1 per part • Total manufacturing costs of SMC bumper is sum of all above costs. • $4.50 + $0.45 + $8.33 + $1 + $0.20+ $1 = $16.48 compared with $44 per part for steel fender. Cost is cheaper for SMC – Weight savings is 6 pounds for steel – 3 pounds SMC = 3 pounds. Copyright Joseph Greene 2004 20 SMC Bumper Beam Costs- Example • Costs (Continued). These are similar for steel and SMC – Purchased items costs including mounting bolts and foam pad for energy absorber. • Mounting bolts and bracket = $1 per assembly in a part – Packaging and shipping costs- typically by weight and ability to stack parts. Fenders do not stack very well. • Packaging and shipping costs are $1 per part – Overhead costs from company- typically 10% of manufactured costs • Overhead costs = 0.10 x $16.48 = $1.65 – Marketing and profit- typically 10-20% of manufactured costs • Profit costs = 0.20 x $16.48 = $3.40 – Total costs • $16.48 + $1+ $1.65 + $3.40 = $22.53 per part for 30,000 parts per year or $0.676 million per year • Some suppliers may not charge for overhead or profit and instead try and get a cheaper price on the SMC material and reduce cycle time and scrap rate. – SMC fender is cheaper and lighter for volumes less than 100,000 per year Copyright Joseph Greene 2004 21 RRIM Fender Costs- Example • Part costs are quoted from suppliers. – The suppliers typically design the bumper beam with their material – The suppliers then quote a part price based upon part weight and volume per year. • Costs are broken into the following areas – Material costs • RRIM is $1.30 per pound for Mica filled polyurethane from Dow Chemical • Part weight in RRIM is 2.5 pounds (Density of RRIM is 1.2 g/cc) and Part thickness is 0.200 inches. • Material part cost is $3.25 per part. – Part costs including scrap rate • RRIM scrap rate is 10% • Scrap rate cost is $0.325 per part. – Tooling costs • RRIM tooling costs for fender is $200,000 for 500,000 parts total. • Amortized tooling costs in 1 year for 30,000 parts. • Tooling part cost is $200,000/30,000 parts = $6.67 per part Copyright Joseph Greene 2004 22 RRIM Fender Costs- Example • Costs (Continued) – Machine costs including labor rate (Cold RRIM is heated in mold) • Machine costs for compression press are $60 per hour. • RRIM cycle time is 1 minute per part or 60 parts per hour. • Machine part costs are $60/60 parts per hour = $1 per part. – Secondary operations costs for trimming and punching holes • • • • Secondary rates are $12 per hour Secondary cycle time is 60 seconds per part or 60 parts per hour. Secondary part costs are $12/60 parts per hour = $0.20 per part Painting costs are needed because of offline paint – Fender is supported in paint buck and then painted in group of 10 – Paint costs are for paint buck tooling, paint, cycle time = $1 per part • Total manufacturing costs of RRIM fender is sum of all above costs. • $3.25 + $0.325 + $6.67 + $1 + $0.20+ $1 = $12.45 compared with $44 per part for steel fender. Cost is cheaper for RRIM than SMC or Steel – Weight savings is 6 pounds for steel – 2.5 pounds RRIM = 3.5 pounds. Copyright Joseph Greene 2004 23 RRIM Fender Costs- Example • Costs (Continued). These are similar for steel and SMC – Purchased items costs including mounting bolts and foam pad for energy absorber. • Mounting bolts and bracket = $1 per assembly in a part – Packaging and shipping costs- typically by weight and ability to stack parts. Fenders do not stack very well. • Packaging and shipping costs are $1 per part – Overhead costs from company- typically 10% of manufactured costs • Overhead costs = 0.10 x $12.45 = $1.25 – Marketing and profit- typically 10-20% of manufactured costs • Profit costs = 0.20 x $12.45 = $2.50 – Total costs • $12.45 + $1+ $1.25 + $2.50 = $17.20 per part for 30,000 parts per year or $0.516million per year • Some suppliers may not charge for overhead or profit and instead try and get a cheaper price on the RRIM material and reduce cycle time and scrap rate. – RRIM fender is cheaper and lighter for volumes less than 100,000 per year than steel. – RRIM is used on Corvette and Viper in 2005 Copyright Joseph Greene 2004 24 Plastic PC/ABS Fender Costs- Example • Part costs are quoted from suppliers. – The suppliers typically design the bumper beam with their material – The suppliers then quote a part price based upon part weight and volume per year. • Costs are broken into the following areas – Material costs • PC/ABS is $1.50 per pound for PC/ABS blend from Dow Chemical • Part weight in PC/ABS is 2.25 pounds (Density of PC/ABS is 1.12 g/cc) and Part thickness is 0.200 inches. • Material part cost is $3.375 per part. – Part costs including scrap rate • Injection molding scrap rate is 1% • Scrap rate cost is $0.0375 per part. – Tooling costs • Injection molding tooling costs for fender is $400,000 for 500,000 parts total. • Amortized tooling costs in 1 year for 30,000 parts. • Tooling part cost is $400,000/30,000 parts = $13.33 per part Copyright Joseph Greene 2004 25 Plastic PC/ABS Fender Costs- Example • Costs (Continued) – Machine costs including labor rate • Machine costs for injection press are $60 per hour. • Injection Molding cycle time is 1 minute per part or 60 parts per hour. • Machine part costs are $60/60 parts per hour = $1 per part. – Secondary operations costs for trimming and punching holes • • • • Secondary rates are $12 per hour Secondary operations are not needed with injection molding Secondary part costs are $0.0 per part Painting costs are needed because of offline paint – Fender is supported in paint buck and then painted in group of 10 – Paint costs are for paint buck tooling, paint, cycle time = $1 per part • Total manufacturing costs of plastic fender is sum of all above costs. • $3.375 + $0.0375 + $13.33 + $1 + $1 = $18.75 compared with $44 per part for steel fender. Cost is cheaper than Steel – Weight savings is 6 pounds for steel – 2.25 pounds = 3.75 pounds. Copyright Joseph Greene 2004 26 Plastic PC/ABS Costs- Example • Costs (Continued). These are similar for steel and SMC and RRIM – Purchased items costs including mounting bolts and foam pad for energy absorber. • Mounting bolts and bracket = $1 per assembly in a part – Packaging and shipping costs- typically by weight and ability to stack parts. Fenders do not stack very well. • Packaging and shipping costs are $1 per part – Overhead costs from company- typically 10% of manufactured costs • Overhead costs = 0.10 x $18.75 = $1.88 – Marketing and profit- typically 10-20% of manufactured costs • Profit costs = 0.20 x $18.75 = $3.76 – Total costs • $18.75 + $1+ $1.88 + $3.76 = $25.39 per part for 30,000 parts per year or $0.762 million per year • Some suppliers may not charge for overhead or profit and instead try and get a cheaper price on the plastic material and reduce cycle time and scrap rate. – Plastic fender is cheaper and lighter for volumes less than 100,000 per year than steel. – Plastic fender is used on Saturn cars in 2005 Copyright Joseph Greene 2004 27 Fender Costs- Example versus volume • Costs depend upon the total volume of parts per year. – Tooling costs are divided by the volume of parts. • As volume goes up the influence of tooling goes down. $ Fender Costs $ per part 45 40 35 30 25 20 15 10 5 0 Steel PC/ABS SMC RRIM 0 100000 200000 300000 400000 500000 600000 Volume of parts Copyright Joseph Greene 2004 28 Quality Issues • RRIM Fender for 2005 Corvette – Poor mixing of mica (reinforcement) causes blisters – Made in Mexico City, Mexico • SMC door for 2005 Corvette – Made in Monterey Mexico – SMC is too thick on bottom and too thin on top of door causing door to crack. • Cause was lack of parallelism in press causing uneven thickness • Solution- shim the mold so that is closes the same until press is fixed. • SMC door for 2005 Corvette – Door does not bond inner and outer. It breaks apart in assembly plant. – Cause • Ashland adhesive is applied robotically but the operator waits 8 minutes to put two pieces together. • The adhesive has already partially cured and has gelled so that is doesn’t flow. • Biggest problem is lack of processing knowledge on operators but they are the cheapest source. Copyright Joseph Greene 2004 29