X-ray tube 2

advertisement

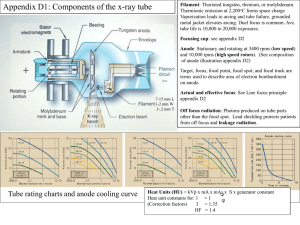

X-ray Tube -2 Line focus principle Heal effect Ratings Tube failure Line-Focus Principle The Effective Focal Spot is the beam projected onto the patient. As the anode angle decreases, the effective focal spot decreases. Diagnostic tube target angles range from 5 to 15°. Advantages & limitations of LFP Advantages The advantage of Line focus is it provides the sharpness of the small focal spot with the heat capacity of the large large focal spot. Smaller target angles will produce smaller effective focal spots and sharper images. limitations Area covered by the beam reduces with target angle To cover a 17” the angle must be 12° To cover 36” the angle must be 14° Anode heel effect (next slide) Anode Heel Effect Due to the absorption of x-rays by the anode heel the radiation intensity on the cathode side of the xray tube is higher than the anode side. This effect is increased when the target angle is reduced Influence of Anode heel effect The difference in the intensity can vary by as much as 45%. If the center is 100% the anode side of the beam can as low as 75% and the cathode as much as 120%. The heel effect should be considered when positioning areas of the body with different thickness or density. The cathode side should be over the area of greatest density. Anode Heel Effect on Focal spot size and Resolution The effective focal spot size and shape change across the projected field The sharpness of the image can be dependent upon which area of the beam coverage you are looking at. Similar to the shape distortion when the tube is not centered. Off Focal Radiation The electrons can rebound and interact with other areas of the anode other than the focal area. These interations can produce x-rays too. This is called Off-Focal Radiation. Control of Off Focal Radiation A diaphragm is placed between the tube and the collimator to reduce off focus rays. But the off focus radiation completely The percentage of off focus radiation increases with kV X-ray Tube Rating Charts The that provide information on the safe exposures and safe operating conditions of x-ray tubes are called tube rating charts With careful use, the x-ray tube can provide long periods of service. Inconsiderate or careless operation can lead to shortened life or abrupt failure. X-ray tubes are very expensive. Cost varies from $2,000 to $20,000. Types of rating charts Radiographic rating chart Anode cooling chart Housing cooling chart Radiographic rating chart This is the most important of the three charts It conveys which radiographic exposures are safe and which are unsafe The chart shows a family of curves for different mA The two axes X & Y show scales of Time and kV respectively For a given mA, any combination of kVp and time that lies below the curve is safe Any combination that lies above the curve of desired mA is unsafe Modern x-ray systems have a microprocessor control that does not allow unsafe exposure to be made. Use of Series of radiographic rating charts Important to use the correct rating chart e.g Rating charts for different filament sizes (focal spot sizes) For different anode rotation speeds For different anode angles For the type of high voltage rectification Radiographic rating charts can be used to check the proper operation of microprocessor control protection circuit Question Radiographic examination of the abdomen with a tube that has a 0.6 mm focal spot and anode rotation of 10,000 rpm requires technique factors of 95 kVp, 150 mAs. Calculate using the correct rating chart, the shortest possible exposure time for this examination. Anode cooling chart Anode cooling charts contain the information about the thermal capacity of an anode and its heat dissipation characteristics. It does not depend on the filament size and the speed of rotation Usually the cooling is rapid at first and slows as the anode cools In addition to knowing the maximum heat capacity the chart is used to determine the length of time required for complete cooling after any level of heat input. Anode cooling chart Anode thermal capacity, HU & Joule The maximum amount of heat that can be stored in the anode without thermal damage In x-ray applications, It is measured in Heat Units (HU) 1HU = 1kVp x 1 mA x 1s (for single phase) Actual heat energy is measured in Joules (J) 1 J = 1 volt x 1 amp x 1s = 1 kV x 1 mA x 1s (here the kV is the direct or the RMS voltage) For single phase kVp = 1.4 kV (rms) For 3 phase or high frequency kVp = kV (rms) Therefore for three phase/high frequency, HU=1.4 x kVp x mA x s Questions Radiographic examination of the lateral lumber spine with a single-phase imaging system requires 98 kVp, 120 mAs. How many heat units are generated by this exposure? 2. A fluoroscopic examination is performed with a singlephase imaging system at 76 kVp and 1.5 mA for 3.5 minutes. How many heat units are generate? 3. Six sequential skull films are exposed with a three-phase generator operate at 82 kV, 120 mAs. What is the total heat generate? 1. Questions A particular examination results in delivery of 50,000 HU to the anoe in a matter of seconds. How long will it take the anode to cool completely? (use the anode cooling chart given in slide 16) 2. How much heat energy (in joules) is produce during a single phase mammographic exposure of 25 kVp, 200 mAS? 1. Housing Cooling Chart The cooling chart for the housing of the x-ray tube has a similar shape as the anode cooling chart. The maximum heat capacity of the housing is in the range of several million heat units. Complete cooling after maximum heat capacity requires from 1 to 2 hours X-ray tube failure All causes of tube failure relate to the thermal characteristics of the tube. When the temperature of the anode during a single exposure is excessive, localized melting and pitting occurs. These surface irregularities lead to variable and reduced radiation output. If the melting is severe, the tungsten vaporizes and can plate the port. This can cause added filtering or interference with the flow of electrons. If the temperature of the anode increases to rapidly, the anode can crack and then become unstable in rotation. Maximum radiographic techniques must never be applied to a cold anode., During long exposures (1 to 3 seconds) the anode may actually glow like a light bulb. The heat may cause a failure of the bearing for the anode or a crack in the glass envelope. Because of the high heat of the filament, the inside of the glass envelope. This will tungsten atoms are slowly vaporized and plate eventually lead to arcing and tube failure. Continuous high mA radiography will actually lead to the filament breakage. Anode faults a. New b. Surface damage due to repeated over load c. Pitting due to slow rotation C d d. Surface damage due to Exceeding of heat capacity Tube Warm-up Procedures By warming the anode through a series of exposures and increasing kVp settings, the anode will build up heat that is needed to avoid fracture of the anode. This process takes a little over one minute put will add to the life of the tube. Close shutters of collimator. Make exposure of 12 mAs @ 70 kVp Wait 15 seconds Make exposure of 12 mAs @ 80 kVp Wait 15 seconds Make exposure of 12 mAs @ 90 kVp Tube warm up is now complete. END V.G.Wimalasena Principal School of radiography