9

Joint-Process

Costing

McGraw-Hill/Irwin

Copyright © 2008 by The McGraw-Hill Companies, Inc. All rights reserved.

9-2

Joint Product Processes

A number of products are produced

from a single raw material input.

Product 1

Single Input

Product 2

Product 3

9-3

Joint Product Processes

Concept: in some industries, a number of products are

produced from a single raw material input.

Key terms:

Joint products – products resulting from a process

with a common input.

Split-off point – the stage of processing where joint

products are separated.

Joint costs – costs of processing joint products

prior to the split-off point.

Final product – ready for sale without further

processing.

Intermediate product – requires further processing

before sale.

9-4

Joint Product Processes

Consider the following

example of an oil refinery.

We will assume only two

products, gasoline and oil.

9-5

Joint Product Processes

Final

products

Intermediate

products

Joint

Costs

Joint

Input

Oil

Common

Production

Process

Final

Sale

Separate

Processing Costs

Gasoline

Split-Off

Point

Separate

Processing

Separate

Processing

Separate

Processing Costs

Final

Sale

9-6

Learning Objective 1

9-7

The Decision Challenge: Which

Joint Products to Produce

Identify final

products possible

from the joint

process.

Forecast the

sales price of

each final

product.

The usual objective in the

production of joint products

is to maximize profits.

Choose the set

of products

with the overall

maximum profit.

Estimate costs

to further process

joint products into

final products.

9-8

Learning Objective 2

9-9

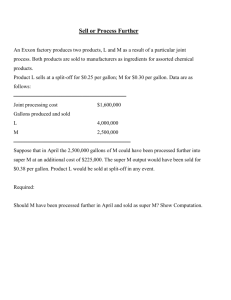

Decision to Sell Products at Split Off

or Process Them Further

Joint product costs incurred prior to the split-off

point are sunk costs — not affected by a

decision to process further after the split-off

point.

A product should be processed beyond the

split-off point only if if the incremental revenue

exceeds the incremental processing costs.

Value is added only if the

incremental value from

processing exceeds the

incremental processing costs.

9-10

Decision to Sell Products at Split Off

or Process Them Further

Sawmill, Inc. cuts logs from which

unfinished lumber and wood chips are the

joint products.

Unfinished lumber is sold “as is” or

processed further into finished lumber.

Wood chips can also be sold “as is” for

landscaping or processed further into 4 × 8

composition boards.

9-11

Decision to Sell Products at Split Off

or Process Them Further

Data about Sawmill’s joint products includes:

Per Log

Wood

Lumber

Chips

Sales value at the split-off point

$

140

$

40

Sales value after further processing

270

50

Allocated joint product costs

176

24

Cost of further processing

50

20

9-12

Decision to Sell Products at Split Off

or Process Them Further

Analysis of Sell or Process Further

Per Log

Wood

Lumber

Chips

Sales value after further processing $

270

$

50

Sales value at the split-off point

140

40

Incremental revenue

130

10

Cost of further processing

50

20

Profit (loss) from further processing $

80

$

(10)

9-13

Decision to Sell Products at Split Off

or Process Them Further

Analysis of Sell or Process Further

Per Log

Wood

Lumber

Chips

Sales value after further processing $

270

$

50

Sales value at the split-off point

140

40

Incremental revenue

130

10

Cost of further processing

50

20

Profit (loss) from further processing $

80

$

(10)

Should we process the lumber

further and sell the wood chips “as is?”

9-14

Learning Objective 3

9-15

Reasons for Allocating Joint Costs

To measure performance based on earnings

To value inventory for financial statements

To estimate casualty losses

To determine and respond to rate regulation

To specify and resolve contractual interests

and obligations

9-16

Learning Objective 4

9-17

Joint Cost Allocation Methods

Physical

measure method

Monetary

measure method

Joint costs are

allocated based on a

proportional measure

(weight, volume, etc.) of

the joint products at the

split-off point.

Joint costs are

allocated based on

the relative values

of the products at the

split-off point.

9-18

Allocating Joint Costs

Joint

costs

If we allocate the joint costs of raising an animal to

the two products based on weight, which product

would receive the largest cost allocation?

Hamburger, because there is more of it.

9-19

Allocating Joint Costs

Joint

costs

If we allocate the joint costs of raising the animal to

the two products based on sales value, would the

steak receive a greater portion of the cost allocation?

Yes, steak has a higher sales value than hamburger.

9-20

Joint Cost Allocation Methods

Let’s look at an example

illustrating the joint cost

allocation methods.

9-21

Monetary Measure Method

Net Realizable Value

If products require further processing beyond

the split-off point before they are marketable,

it may be necessary to estimate the net

realizable value (NRV) at the split-off point.

NRV

=

Final

Sales

Value

–

Added

Processing

Costs

9-22

Monetary Measure Method

Net Realizable Value

Joint

costs

Joint

input

Intermediate

products

Oil

Common

production

process

Separate

processing

Final

sale

Separate

processing costs

Gasoline

Split-off

point

Final

products

Separate

processing

Separate

processing costs

Final

sale

9-23

Monetary Measure Method

Net Realizable Value

Joint conversion

cost = $225,000

Joint material

cost = $275,000

Oil

Separate

Processing Costs

$200,000

Common

production

process

Gasoline

Split-off

point

Separate

processing

Sales

value

$500,000

Sales

Separate

value

processing $1,200,000

Separate

processing costs

$500,000

9-24

Monetary Measure Method

Net Realizable Value

Product

Oil

Sales value

Less additional processing costs

Estimated NRV at split-off point

Proportionate share:

Gasoline

Total

$ 500,000 $ 1,200,000 $ 1,700,000

?

?

?

?

?

?

?

?

Allocated joint costs:

?

?

9-25

Monetary Measure Method

Net Realizable Value

Product

Oil

Sales value

Less additional processing costs

Estimated NRV at split-off point

Proportionate share:

Gasoline

Total

$ 500,000 $ 1,200,000 $ 1,700,000

200,000

500,000

700,000

$ 300,000 $ 700,000 $ 1,000,000

?

?

Allocated joint costs:

?

?

9-26

Monetary Measure Method

Net Realizable Value

Product

Oil

Sales value

Less additional processing costs

Estimated NRV at split-off point

Proportionate share:

$300,000 ÷ $1,000,000

$700,000 ÷ $1,000,000

Gasoline

Total

$ 500,000 $ 1,200,000 $ 1,700,000

200,000

500,000

700,000

$ 300,000 $ 700,000 $ 1,000,000

30%

70%

Allocated joint costs:

?

?

9-27

Monetary Measure Method

Net Realizable Value

Product

Oil

Sales value

Less additional processing costs

Estimated NRV at split-off point

Proportionate share:

$300,000 ÷ $1,000,000

$700,000 ÷ $1,000,000

Allocated joint costs:

$500,000 × 30%

$500,000 × 70%

Gasoline

Total

$ 500,000 $ 1,200,000 $ 1,700,000

200,000

500,000

700,000

$ 300,000 $ 700,000 $ 1,000,000

30%

70%

$ 150,000

$ 350,000

9-28

Monetary Measure Method

Net Realizable Value

Product

Oil

Estimated NRV at split-off point

Less allocated joint costs

Gross margin

Gasoline

Total

$ 300,000 $ 700,000 $ 1,000,000

150,000

350,000

500,000

$ 150,000 $ 350,000 $ 500,000

Gross margin as a percent of sales

?

?

?

9-29

Monetary Measure Method

Net Realizable Value

Product

Oil

Estimated NRV at split-off point

Less allocated joint costs

Gross margin

Gross margin as a percent of sales

$150,000 ÷ $300,000

$350,000 ÷ $700,000

$500,000 ÷ $1,000,000

Gasoline

Total

$ 300,000 $ 700,000 $ 1,000,000

150,000

350,000

500,000

$ 150,000 $ 350,000 $ 500,000

50.0%

50.0%

50.0%

The net realizable value method results in

equal gross margin percentages for all products.

9-30

Physical Measure Method

The physical measure method may be used when

Output product prices are highly volatile.

Many additional processes occur between the

split-off point and the first point of marketability.

Market prices are unavailable for products

provided via cost-plus contracts.

9-31

Physical Measure Method

Joint

costs

Joint

input

Oil

240,000 gallons

Gasoline

360,000 gallons

Common

production

process

Split-off

point

9-32

Physical Measure Method

Joint conversion

cost = $225,000

Joint material

cost = $275,000

Oil

240,000 gallons

Gasoline

360,000 gallons

Common

production

process

Split-off

point

9-33

Physical Measure Method

Product

Oil

Output quantities in gallons

Proportionate share:

240,000

Gasoline

360,000

?

?

Allocated joint costs:

?

?

Total

600,000

9-34

Physical Measure Method

Product

Oil

Output quantities in gallons

Proportionate share:

240,000 ÷ 600,000

360,000 ÷ 600,000

240,000

Gasoline

360,000

40%

60%

Allocated joint costs:

?

?

Total

600,000

9-35

Physical Measure Method

Product

Oil

Output quantities in gallons

Proportionate share:

240,000 ÷ 600,000

360,000 ÷ 600,000

Allocated joint costs:

$500,000 × 40%

$500,000 × 60%

240,000

Gasoline

360,000

40%

60%

$ 200,000

$ 300,000

$275,000 joint material cost plus

$225,000 joint conversion cost

Total

600,000

9-36

Choosing Among Joint Cost

Allocation Methods

Joint costs are truly

common costs.

Which joint cost allocation

method should we use?

We get a different result

with each method.

It is impossible to separate

the portion of joint costs

attributable to one product

on a cause and effect

basis.

9-37

Choosing Among Joint Cost

Allocation Methods

That makes the choice of methods

somewhat arbitrary.

Regardless of the method we choose, we

really need to be careful using allocated

costs for decision-making purposes.

9-38

Choosing Among Joint Cost

Allocation Methods

Choose the joint-cost allocation method that maximizes regulated

profits or cost reimbursements.

Do not base product or service production decisions on joint

margins (I.e., after joint-cost allocation) unless the choice is in

response to regulatory opportunities.

Clearly define how to allocate joint costs in contractual agreements

among parties that share outputs and joint costs of joint processes.

9-39

Learning Objective 5

9-40

What Are By-Products?

They are incidental to

a production process.

Examples

Lumber production:

wood chips

Fertilizer production:

methane gas

Their sales value is

minimal.

Do not allocate joint

costs to by-products

9-41

Accounting for By-Products

Two commonly used methods of

accounting for by-products are . . .

Realized Value Approach

By-product NRV is treated as other

revenue.

Net Realizable Value Approach

By-product NRV is deducted from joint

production costs before allocation.

9-42

Accounting for By-Products

Joint

costs

Joint

input

Common

production

process

Major

product

Major

product

By-products

Split-off

point

Relatively low

value or quantity

when compared to

major products

9-43

Accounting for By-Products

Joint conversion

cost = $50,000

Joint material

cost = $50,000

Common

production

process

Major

product

Sales

value

$100,000

Major

product

Sales

value

$70,000

By-products

Split-off

point

Separate

processing

Separate

processing costs

$400

Sales

value

$1,500

9-44

Accounting for By-Products

Major product revenue

Other revenue

Total revenue

Cost of sales:

Joint production costs

Less by-product NRV

Adjusted cost of sales

Gross margin

By-Product

Accounting Method

2

1

$ 170,000

$ 170,000

?

?

?

?

?

?

?

?

?

?

?

?

Major product revenue = $100,000 + $70,000

9-45

Accounting for By-Products

Major product revenue

Other revenue

Total revenue

Cost of sales:

Joint production costs

Less by-product NRV

Adjusted cost of sales

Gross margin

By-Product

Accounting Method

2

1

$ 170,000

$ 170,000

0

1,100

170,000

171,100

?

?

?

?

?

?

?

?

By-product NRV = $1,500 – $400 = $1,100

9-46

Accounting for By-Products

Major product revenue

Other revenue

Total revenue

Cost of sales:

Joint production costs

Less by-product NRV

Adjusted cost of sales

Gross margin

By-Product

Accounting Method

2

1

$ 170,000

$ 170,000

0

1,100

170,000

171,100

100,000

?

?

?

100,000

?

?

?

Joint production costs = $50,000 material + $50,000 conversion

9-47

Accounting for By-Products

Major product revenue

Other revenue

Total revenue

Cost of sales:

Joint production costs

Less by-product NRV

Adjusted cost of sales

Gross margin

By-Product

Accounting Method

2

1

$ 170,000

$ 170,000

0

1,100

170,000

171,100

100,000

1,100

98,900

$ 71,100

100,000

0

100,000

$ 71,100

9-48

By-Products: Some Complications

The preceding example assumes the byproduct has been sold.

If the by-product is unsold . . .

Using method 2, the $1,100 by-product

NRV is deducted from finished goods

inventory or work-in-process inventory if

unfinished.

Using method 1, the $1,100 by-product

NRV is placed in a by-product inventory

account.

9-49

Disposal of Scrap or Waste

Waste is a by-product with negative NRV. (Cost

of disposal exceeds sales value)

Waste is disposed of at minimum cost.

Waste disposal cost is charged to

manufacturing overhead

and applied to other

products as part of the

manufacturing overhead

allocation process.

9-50

Learning Objective 6

9-51

Allocation of Joint Costs –

Other Economic Value Methods

In addition to net realizable value

Relative sales value at split-off

Further processing costs not considered

Constant gross margin percentage

Use total sales value of all products

Compute overall gross margin for process

Set the same gross margin for all products

Allocate joint costs so as to achieve that

uniform gross margin

9-52

End of Chapter 9