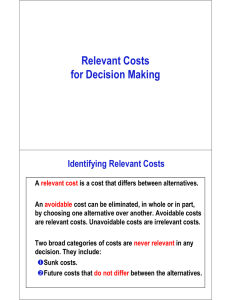

relevant cost

advertisement

Chapter 12 Cost Concepts for Decision Making A relevant cost is a cost that differs between alternatives. Identifying Relevant Costs Costs that can be eliminated (in whole or in part) by choosing one alternative over another are avoidable costs. Avoidable costs are relevant costs. Unavoidable costs are never relevant and include: Sunk costs. Current and future costs that do not differ between the alternatives. Differential Revenues and Costs Example: You have a job paying $1,500 per month in your hometown. You have a job offer in a neighboring city that pays $2,000 per month. The commuting cost to the city is $300 per month. Differential revenue: $2,000 – $1,500 = $500 Differential cost: $300 Net benefit: $200 Opportunity Costs The potential benefit that is given up when one alternative is selected over another. Example: If you were not attending college, you could be earning $15,000 per year delivering pizzas. Your opportunity cost of attending college for one year is $15,000. The Matter of Opportunity Cost The economic benefits that are foregone as a result of pursuing some course of action. Opportunity costs are not actual dollar outlays and are not recorded in the accounts of an organization. Sunk Costs Sunk costs cannot be changed by any decision. They are not differential costs and should be ignored when making decisions. Example: You bought an automobile that cost $10,000 two years ago. The $10,000 cost is sunk because whether you drive it, park it, trade it, or sell it, you cannot change the $10,000 cost. Adding/Dropping Segments One of the most important decisions managers make is whether to add or drop a business segment such as a product line, a store, or a division. Adding/Dropping Segments DECISION RULE A company should drop a segment only if its fixed cost savings exceed lost contribution margin. Adding/Dropping Segments DECISION RULE Eliminate the segment only if overall profit would increase. Compare the contribution margin that would be lost to the costs that would be avoided if the segment is to be dropped. Beware of Allocated Fixed Costs Allocations can make a segment look less profitable than it really is. Differential Approach Compare benefits of alternative(s) under consideration to related costs. Focus only on relevant costs. Comparative Income Statement Approach The solution can also be obtained by preparing comparative income statements showing results with and without the segment. Differential and Comparative Cost Approaches The management of a company is considering a new labor saving machine ($15,000 in savings) that rents for $3,000 per year. Data about the company’s annual sales and costs with and without the new machine are: Sales (5,000 units @ $40 per unit) Less variable expenses: Direct materials (5,000 units @ $14 per unit) Direct labor (5,000 units @ $8 and $5 per unit) Variable overhead (5,000 units @ $2 per unit) Total variable expenses Contribution margin Less fixed expense: Current Situation $ 200,000 Situation With New Machine $ 200,000 Differential Costs and Benefits - 70,000 40,000 10,000 120,000 80,000 70,000 25,000 10,000 105,000 95,000 15,000 15,000 15,000 Differential and Comparative Cost Approaches As you can see, the only costs that differ between the alternatives are the direct labor costs savings and the increase in fixed rental costs. Situation With New Machine $ 200,000 Current Situation $ 200,000 Sales (5,000 units @ $40 per unit) Less variable expenses: We can analyze the70,000 decision by70,000 Direct materials (5,000 unitsefficiently @ $14 per unit) Direct labor (5,000 units @ at $8 and per unit) costs and 40,000 looking the $5 different revenues25,000 Variable overhead (5,000 units @ $2 per unit) 10,000 10,000 Total variable expenses and arrive at the same solution 120,000 105,000 Contribution margin 80,000 95,000 Net Advantage to Renting the New Machine Less fixed expense: Decrease in direct labor costs (5,000 units @ $3 per unit) $ 15,000 Other 62,000 62,000 Increase in fixed rental expenses (3,000) Rent on newNet machine 3,000 annual cost saving from renting the new machine $ 12,000 Total fixed expenses 62,000 65,000 Net operating income $ 18,000 $ 30,000 . Differential Costs and Benefits 15,000 15,000 (3,000) (3,000) 12,000 The Make or Buy Decision A decision concerning whether an item should be produced internally or purchased from an outside supplier is called a “make or buy” decision. The Make or Buy Decision DECISION RULE In deciding whether to accept an outside supplier’s offer, isolate the relevant costs of making the part by eliminating: – The sunk costs. – The future costs that will not differ between making or buying the parts. – Then compare the result to the supplier’s offer. Special Orders A special order is a one-time order that is not considered part of the company’s normal ongoing business. When analyzing a special order, only the incremental costs and benefits are relevant. Since existing fixed manufacturing overhead costs would not be affected by the order, they are not relevant. Special Orders Decision Rule Accept the order if it results in positive contribution margin and does not disrupt the pricing of regular products. Constrained Resources When a limited resource of some type restricts the company’s ability to satisfy demand, the company is said to have a constraint. The machine or process that is limiting overall output is called the bottleneck – it is the constraint. Utilization of a Constrained Resource-Decision Rule • • • When a constraint exists, a company should select a product mix that maximizes the total contribution margin earned since fixed costs usually remain unchanged. A company should not necessarily promote those products that have the highest unit contribution margin. Rather, it should promote those products that earn the highest contribution margin in relation to the constraining resource. Utilization of a Constrained Resource: An Example Ensign Company produces two products and selected data is shown below: Product 2 1 Selling price per unit Less variable expenses per unit Contribution margin per unit Current demand per week (units) Contribution margin ratio Processing time required on Machine A1 per unit $ 60 36 $ 24 2,000 40% 1.00 min. $ 50 35 $ 15 2,200 30% 0.50 min. Utilization of a Constrained Resource • Time on Machine A1 is the constrained resource which is being used at 100% of its capacity. • There is excess capacity on all other machines. • Machine A1 has a capacity of 2,400 minutes per week. Should Ensign focus its efforts on Product 1 or 2? Utilization of a Constrained Resource The key is the contribution margin per unit of the constrained resource. Product 2 1 Contribution margin per unit Time required to produce one unit Contribution margin per minute $ ÷ 24 1.00 min. ÷ $ 24 $ 15 0.50 min. $ 30 If there are no other considerations, the best plan would be to produce to meet current demand for Product 2 and then use remaining capacity to make Product 1. Joint Product Costs • In some industries, a number of end products are produced from a single raw material input. • Two or more products produced from a common input are called joint products. • The point in the manufacturing process where each joint product can be recognized as a separate product is called the split-off point. Joint Products Joint Costs Joint Input Common Production Process Engine Oil Gasoline Chemicals Split-Off Point Separate Processing Final Sale Final Sale Separate Processing Separate Product Costs Final Sale Sell or Process FurtherDecision Rule Joint costs are irrelevant in decisions regarding what to do with a product from the split-off point forward. It will always be profitable to continue processing a joint product after the splitoff point so long as the incremental revenue exceeds the incremental processing costs incurred after the split-off point. Sell or Process Further: An Example • Sawmill, Inc. cuts logs from which unfinished lumber and sawdust are the immediate joint products. • Unfinished lumber is sold “as is” or processed further into finished lumber. • Sawdust can also be sold “as is” to gardening wholesalers or processed further into “prestologs.” Sell or Process Further Data about Sawmill’s joint products includes: Sales value at the split-off point Sales value after further processing Allocated joint product costs Cost of further processing Per Log Lumber Sawdust $ 140 $ 40 270 176 50 50 24 20 Sell or Process Further Analysis of Sell or Process Further Per Log Sales value after further processing Sales value at the split-off point Incremental revenue Cost of further processing Profit (loss) from further processing Lumber Sawdust $ $ $ 270 140 130 50 80 $ 50 40 10 20 (10) End of Chapter 12