msm question bank

advertisement

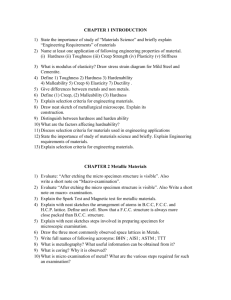

MSM QUESTION BANK SR NO 1. 2. 3. 4. 5. 6. 7. SR NO CHAP-1 INTRODUCTION State the importance of study of “Materials Science” and briefly explain 1.1, “Engineering Requirements” of materials. 2.4 Define (1) Creep, (2) Malleability (3) Hardness 3.2 – 3.10 Name at least one application of following engineering properties of material. (i) Hardness (ii) Toughness (iii) Creep Strength (iv) Plasticity (v) Stiffness (vi) 3.2 -3.10 Ductility (vi) Harden ability Explain selection criteria for engineering materials. 4.4 – 4.2 What is modulus of elasticity? Draw stress strain diagram for Mild Steel and 3.2 Cementite. 3.4 -3.5 State utmost required engineering properties for following applications: 1. Bolt 2. Gear 3. Helical Spring 4. Shaft 5. Cutting Tool 6. Cylinder of I.C. 3.1 Engine 7. Gas Turbine Blade What is material? Give the classification of engineering materials. 2.1 CHAP-2 METALLIC MATERIALS 1. Give differences between metals and non metals. 2. Draw neat sketch of metallurgical microscope. Explain its construction. Evaluate: “After etching the micro specimen structure is visible”. Also write a short note on “Macro-examination”. 3. 4. 5. 6. O.P. KHANNA What is micro examination of metal? What are the various steps required for such an examination? Explain with neat sketches steps involved in preparing specimen for microscopic examination. Differentiate: Macrostructure and Microstructure Examination. OR Compare and contrast: micro and macro examination ATUL 1-3 3 - 14 3 - 14 14 - 16 5–6 3 - O.P. KHANNA ATUL - - 42.1 - 42.7 45 42.3 45 42.3 49 42.7 - 7. What is metallography? What useful information can be obtained from it? 42.1 - 8. List the different types of etchants. 42.6 - - 46,50 - - O.P. KHANNA ATUL 9. 10. Explain the Spark Test and Magnetic test for metallic materials. Write full names of following acronyms: BHN ; AISI ; ASTM ; TTT SR NO 1. CHAP-3 CRYSTALLIZATION OF METAL What is coring? Why it is observed? Define Critical Cooling Rate of steel and show the same on a TTT diagram with complete labelling. Draw the three most commonly observed space lattices in Metals. What is the significance of Liquidus, Solidus and Solvus line in phase diagram? State the difference between impurities and alloying elements. State importance of alloying. State effect of grain size on mechanical properties of material. 2. 3. 4. 5. 6. 40.24, 40.21 35.19 25 39.1 - - - 40.34 - SR NO 1. 2. 3. 4. 5. 6. 7. SR NO 1. 2. 3. 4. 5. 6. 7. 8. SR NO 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. CHAP-4 O.P. I C DIAGRAM KHANNA 40.1 Define Allotropy. Explain allotropy of Iron. 40.7 Draw Iron Carbon Equilibrium diagram. 38.1,38.2 What is solid solution? Explain types of solid solution. Also give Hume 38.4 Rothery’s Rules. 39.9 What is Gibb’s phase rule? Define system, phase and degree of freedom. Show that the degree of freedom at eutectic point in a binary phase diagram is zero. 40.26,40.27 Draw microstructure of eutectoid steel. 38.4 Explain in brief: factors affecting formation of solid solution(Hume rothery) Draw microstructure of (i) 04 % carbon steel and (ii) eutectoid steel (iii)eutectic cast iron at room temperature. CHAP-5 CAST IRON, WROUGHT IRON, STEEL Give composition, properties and uses of malleable cast iron. Explain gray cast iron in terms of microstructure, properties, composition & applications. What is “Wrought Iron”? Enlist the properties and uses of it. State function of following alloying elements in steel : Sulphur ; Nickel ; Chromium ; Boron Differentiate between white cast iron and grey cast iron. State composition, specific properties and applications of high carbon steel Classify different types of cast iron. Why silicon is added to cast iron? Explain the effects of any four alloying elements on the properties of cast iron. Enlist copper and its alloys. Explain any two of them along with its properties and use. CHAP-6 HEAT TREATMENT Which are various Surface Hardening processes? Explain Induction Hardening process with sketch. Which are the objectives of Heat Treatment? Give difference between Annealing and Normalising. Draw cooling curve of (i) pure metal and (ii) An alloy of two metals which are completely soluble in liquid and solid phase. Write the procedure for Jominy end quench practical and discuss its conclusion. Briefly explain why ferritic and austenitic stainless steels are not heat treatable. Differentiate between austempering and martempering. Explain flame-hardening process in brief State Case Hardening processes and explain any one in detail. State Surface Hardening processes and explain any one. ATUL 53 55 PPT 89,90 94 90 - O.P. KHANNA ATUL 5.7 5.6, 127(best) 124, 5.3 - 133 - 5.10,5.6 5.13 124 135 5.2 121 6.1 201 O.P. KHANNA 44.1, 44.15 43.1 43.3,43.7 ATUL 178 43.23 145 157(best) 96, 95(fig.4.15) 272 43.41 43.42 43.19,43.19 44.13 44.1 44.1 173.174, 175 166,167 183 178 178 39.4 SR NO 1. 2. 3. 4. 5. 6. 7. 8. SR NO 1. 2. 3. 4. SR NO 1. 2. 3. 4. CHAP-7 NON-FERROUS METALS What are the properties of bearing alloys. What are the properties of aluminium alloys Define “Alloy”. Also state composition, properties & uses of any two copper alloys. Give composition and uses of Monel metal and Nichrome. Give composition, properties and uses of Y alloy. What are the purposes of alloying? Give effects of Nickel as an alloying element. State the properties and applications of monel metal and inconel. Specify, with reasons alloy suitable for the manufacture of : Bolts and Nuts ; Lathe Bed ; Milling Cutter State composition and specific applications of : Muntz metal ; German silver ; Naval brass O.P. KHANNA ATUL 9.1, 6.8 6.1 201 6.16 - - - - 206 CHAP-8 POWDER METALLURGY Which are advantages and limitations of powder metallurgy? Explain any two methods for production of metal powders. What is powder metallurgy? Describe various steps involved in powder metallurgy with each step controlling properties of final sintered component. Give advantages, limitation & applications of powder metallurgy. O.P. KHANNA ATUL 53.2,53.4 53.6 53.12 209 213 217 53.3 208 CHAP-9 NON DESTRUCTIVE TESTING What is non destructive test? List various non destructive tests. Explain X ray Radiography. Explain Ultrasonic testing with advantages and limitations. Explain liquid penetration test. Expalin Magnetic particle testing. O.P. KHANNA ATUL 49.20,49.22 256,262 49.19 49.30 49.25 264 258 268 For Mid semester examination Chap-1 INTRODUCTION Chap-2 METALLIC MATERIALS Chap-4 I C DIAGRAM Chap-6 HEAT TREATMENT Chap-8 POWDER METALLURGY Chap-9 NON DESTRUCTIVE TESTING -