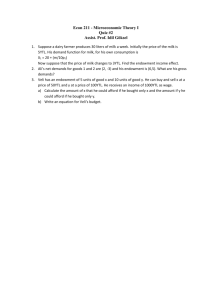

milk and milk products

advertisement

MILK MILK PRODUCTS COMPOSITION OF MILK Water - 87-88% Total milk solids - 12-13% CARBOHYDRATE – 5% Lactose – main CHO Low solubility, may precipitate out as grainy substance during heat treatments Converts to lactic acid with souring or fermentation – lactose stays in whey Part of milk solids non fat Less sweet than sucrose FAT 3-4% for whole milk, varies according to state law Primarily triglycerides, then phospholipids, sterols Mix of unsaturated, monounsaturated, polyunsaturated High level of short chain – contribute to milk flavor and low melting point of butter Fat globules less dense than water less stable Milk is an emulsion “Creaming” process – fat rises to the top PROTEINS CASEIN Primary proteingroup of similar proteins – micellular proteins Colloidally dispersed, poorly hydrated, calcium sensitive, excellent emulsifiers Can be separated by acidification to bring to isoelectric point (4.6) Rennin- enzyme also precipitates casein clotting, clabbering, curdling when milk sours WHEY Lactalbumin and lactoglobulin More hydrated than casein, denatured and precipitated by heat >600C or 1400F forms scum on bottom of pan scorches Not precipitated with acid or rennet Lactose precipitates with the whey Enzymes – lipase, protease, alkaline phosphatase Casein and whey part of milk solids non fat VITAMINS Fat soluble - naturally in fat component in whole milk High in vitamin A, some D Fair source of water soluble vitamins (B), excellent riboflavin Small amounts of vitamin C Fortified with Vitamin A and D MINERALS Calcium Phosphorus Magnesium Potassium Sodium Chloride Sulfur PIGMENTS Fresh whole milk ivory caused by refraction of light in dispersed particles Skim milk bluish cast Carotene and riboflavin yellow tinge Riboflavin green tone FLAVOR OF MILK Mouthfeel due to emulsified fat, colloidally dispersed proteins, lactose, milk salts Fresh milk contains acetone, actealdehyde, methyl ketones, and short chain fatty acids to provide aroma Normally a mild sweet flavor Heat processing changes flavor Affected by physical condition of cow and composition of the feed OFF FLAVORS Main cause pasture weeds Old or moldy feed rancid or bitter flavors Oxidation of fat oxidized phospholipids fishy odors Exposure to sunlight changes riboflavin and milk proteins CLASSIFICATION OF MILK SOLUTION Sugar - lactose Water-soluble vitamins thiamin & riboflavin Mineral salts, and minerals COLLOIDAL DISPERSION Casein bound to calcium phosphate in micelle - too big to dissolve Whey proteins EMULSION Unstable due to large droplet phase of fats, temporary MILK PROCESSING SANITATION AND QUALITY PHF Grade A Pasteurized Milk Ordinance USDA, US Public Health Service (FDA) and state departments of agriculture regulate milk and milk products Voluntary GRADES Grade A – available to consumer – fluid milk Grade B & C higher bacterial count, safe, wholesome Grade US extra and US standard used for dried milk Grades based on bacterial count of fresh milk Given on a voluntary fee for service basis PASTEURIZATION Treating with heat to kill pathogens and inactivate spoilage enzymes; some spoilage organisms may survive so cool promptly and hold under refrigeration Destroys lipase which catalyzes hydrolytic rancidity Process is time/temperature dependent Alkaline phosphatase - same heat denaturation curve as milk pathogens; presence indicates inadequate pasteurization TIME/TEMPERATURES Use high temperature, short time (H.T.S.T.) 162F, 72C for 15 seconds Low temperature longer time Ultra-high temperature (U.H.T.) growing, 280F for 2-4 sec. May develop cooked flavor, use in shelf stable products, often used with cream, eggnog, half and half STERILIZATION Only occurs with ultra-high temperatures for 2-6 seconds Can be aseptically packaged; no refrigeration until opened HOMOGENIZATION Prevents creaming; maintains more uniform composition, optional process Mechanically reduces size, increases number of fat globules permanently emulsifies fat globules Characteristics: Whiter milk More viscous, creamy milk More bland - fat globules smaller Less stable to light Increased chance of rancidity FORTIFICATION Whole milk - optional addition of A & D Lowfat milk, nonfat, low-fat chocolate - Must be fortified for A Addition of D optional but routinely practiced To increase viscosity, appearance, and nutritive value of lowfat milk, nonfat milk solids may be added – states protein fortified or fortified with protein BLEACHING FDA - benzoyl peroxide or benzoyl peroxide with potassium alum, calcium sulfate, and magnesium carbonate to be used as a bleaching agent in milk to remove pigments such as carotenoids and chlorophylls Vitamin A or precursors may be destroyed sufficient A added into milk or curd (for cheesemaking) TYPES OF MILK FLUID Must be free of pathogenic bacteria Fat content and % of MSNF subject to FDA regulations Flavored – same nutrients as milk to which flavor added Certified milk – limited distribution due to cost, sanitary standards very high Eggnog- mixture of dairy ingredients (cream, milk) egg yolk containing ingredients, nutritive carbohydrate sweeteners. OTHER FLUID MILK Canned whole milk – homogenized, sterilized, canned aseptically Frozen whole milk – homogenized, pasteurized, fat separates when thawed, protein denatured by freezing Skim or nonfat – as much fat as possible removed, minimum of MSNF, fortified with vitamin A. Optional: vitamin D, emulsifiers, stabilizers Low-fat milk – some fat removed, named according to fat remaining, minimum MSNF, fortified with vit. A. Optional: Vit. D, emulsifiers, stabilizers Labeled with protein fortified if MSNF >10% CONCENTRATED MILKS EVAPORATED MILK Concentrated through process of evaporation Evaporated in a vacuum chamber Whole or nonfat – 60% of H2O removed Homogenized, fortified, canned, sterilized Increasingly less stable with progression of concentration and heat may coagulate prevent by forewarming Maillard reaction light tan color Reconstitute 1:1 ratio CONDENSED MILK Similar in content and use to evaporated milk NOT sterilized Perishable at temperatures above 450F SWEETENED CONDENSED MILK Concentrated whole or nonfat milk 60% of H2O removed Sweetened with sucrose or dextrose prior to concentration 40-45% sugar level, may cause grittiness Pasteurized, not sterilized due to high concentration of sugar Used in pie filling – thickening occurs because concentrated proteins coagulate from the effect of added acid DRIED MILK Processed from whole or nonfat milk (more common) Condensed 2/3 of H2O removed Sprayed into heated vacuum chamber less than 5% moisture level Most nonfat fortified “Instant” or “agglomerated” – some moisture added back pourable, dispersible, in cold H2O May also dry buttermilk, whey CULTURED AND FERMENTED MILK AND MILK PRODUCTS CULTURED/FERMENTED Cultured products fermented by addition of bacterial culturesStreptococci and Lactobacilli Ferment lactose lactic acid; create low pH to coagulate casein Acidified products – souring milk with acid, with or without microorganisms Cultured and acidified products contain different amounts of lactic acid different flavors BUTTERMILK Traditionally liquid left after churning butter, differs from nonfat milk due to content of phospholipids and proteins from fat globule, NFDM solids added Cultured buttermilk – pasteurized lowfat or nonfat milk with Lactobacilli and Streptococci added Acidified buttermilk – lactic acid producing bacteria not compulsory Smooth cultured flavor, high acid content useful in cooking SOUR CREAM Traditionally heavy cream soured Pasteurized, homogenized fresh light cream Coagulated similar to buttermilk Flavors, stabilizers added Proteolytic bacterial enzyme activity may cause bitter flavor after 3-4 weeks YOGURT Culture pasteurized dairy product with lactobacillus bulgaricus and streptococcus thermophilis National Yogurt Association seal for live and active bacteria; at least 100 million bacteria/gram at time of manufacture Yogurt with viable strains of bacteria eaten in sufficient quantities some will survive passage through stomach and release lactase in the intestine OTHER PRODUCTS Acidophilus milk - pasteurized low-fat or nonfat milk with Lactobacillus Acidophilus added, Bacteria can live in intestine and produce number of B vitamins Reduced Lactose milk - pasteurized milk treated with lactase sweeter than regular milk Kefir– fermented dairy products, kefir grain yields bacteria added to milk Koumiss – milk heated before fermentation Ferments to yield soft curd with yeasty sour curd with mild alcoholic flavor MILK SUBSTITUTES Imitation milk – combination of several nondairy ingredients; nutritionally inferior Substitute milk – nutritionally equivalent; reduced calories or fat, usually milk derivatives ( casein, casein salts, whey) Filled milk – substitute milk with milkfat replaced with vegetable oil CREAMS DESCRIPTION High fat component separated from milk Federal standards must have at least 18% milkfat Yellow, fat-soluble pigments visible TYPES Light coffee cream – 18-30% Light whipping cream – 30-36% Heavy cream – 36% butterfat, minimum Half and half – cream diluted with nonfat milk 10.5% PRINCIPLES OF USING MILK AND MILK PRODUCTS EFFECTS OF HEAT Prolonged heating adversely affects: Flavor – dependent on length of time of heating and temperature reached Due to production of sulfur compounds from denaturation of whey proteins Due to caramelized flavor from Maillard reaction Odor Cooking properties HEAT AND MILK PROTEINS Heated milk forms precipitate on bottom and sides of pan – coagulated whey proteins Precipitated proteins tend to scorch One whey protein component produces a low volume in yeast breads made with unheated milk- scalded milk greater volume in yeast breads Heated in uncovered pan forms “skin” – coagulated proteins, fat, minerals because milk drying out on top Prevents steam from escaping boil over HEAT AND MILK PROTEINS Casein changes little under normal heating May not take place until milk has been boiled for 14 hours Temperatures above boiling cleavage of peptide and phosphate bonds In concentrated milks coagulation greater due to protein concentration Unstable emulsion like soured milks accelerate coagulation with heat HEAT AND MILK MINERALS Decreases dispersion of calcium phosphate Precipitates and becomes enmeshed in whey proteins on bottom of pan EFFECT OF ACID Normal pH = 6.5-6.7 Add acid pH decreases Below 5.1 casein destabilizes At pH 4.5 casein salts formed milk curdles Coagulum traps whey which is released when curd is cut, stirred, or heated Curd is soft, fragile Cheese from acid coagulation is low in calcium compared to whey Cream of tomato soup – separates milk proteins Acids in fruits curdle milk in smoothies Add lemon juice to sauce at end of cooking EFFECT OF ENZYMES Coagulate proteins Clabbered by rennin – stomach of milkfed calves – extract is rennet, now use pepsin from hog stomachs Genetically engineered rennet from genetically modified Aspergillus mold Clots are tough, rubbery, contain most of calcium Add to warm milk for optimal activity EFFECT OF ALKALI Baking soda, for example Stabilizes colloidal dispersions EFFECT OF POLYPHENOLIC COMPOUNDS Tannins Astringent compounds found in fruit, vegetables, plant foods Produce curdling especially if soured or destabilized by heat Potatoes cause curdling in scalloped dishes EFFECT OF SALT In high concentration will destabilize a gel Influences coagulation of casein Ham added to milk-based dish high sodium content curdles surrounding liquid