View in PowerPoint

advertisement

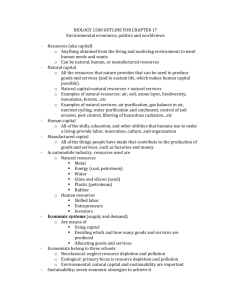

Implementing Pollution Prevention “P2 Dee-fusion” Clearwater, FL June 7, 2000 Cam Metcalf Executive Director jcmetc01@gwise.louisville.edu 502-852-0965 1 Driving Forces on Legislation Property Owners: NIMBY, “Universal Backyard” Taxpayers: Pressured by rising disposal fees Environmentalists: Concerns of ecological effects Industries: Fear punitive regulations & legislation 2 Driving Forces on Legislation Property Owners: NIMBY, “Universal Backyard” Taxpayers/Agency: Pressured by rising treatment fees Environmentalists: Concerns of ecological effects Industries: Fear punitive regulations & legislation 3 Our “Universal Backyard” NIMBY NOTE BANANA CAVE NOPE 4 ‘90 Pollution Prevention Act Defines Source Reduction as: Any practice which reduces the amount of any hazardous substance, pollutant, or contaminant entering any waste stream or otherwise released into the environment (including fugitive emissions) prior to recycling, treatment, or disposal; and reduces the hazards to public health and the environment associated with the release of such substances, pollutants, or contaminants. 5 Hierarchy for Pollution Prevention (P2) Source Reduction Reuse/Recycling Energy Recovery Treatment Disposal 6 P2 Programs are Selling Multi-Media Approaches W ater A ir S olids T ime E nergy 7 Cross-Media Transfer Waste Gaseous/ Particles Waste Processing Waste Processing Waste Processing Solid Residuals Wastewater Gaseous/ Particles Land Watercourse or Impoundment or Deep Well Air 8 Cross-Media Transfer (cont.) An example of cross-media transfer: Facility installs a wet scrubber: VOCs transferred from air to water, which is discharged into a nearby stream. Discharge to stream requires water permit modification: air stripper is installed to meet permit requirements--VOCs transferred back to the air. New air stripper requires another air permit. After 3 permits, 3 years, & $3,000,000 the same amount of contaminants are reaching the air! Pollution Prevention Review, Steven Anderson & Jeanne Herb 9 Process Flow Flow Diagram Diagram Process 10 P2 Means Process modifications; Feedstock substitutions; Product reformulation; Management practices or housekeeping alterations; Recycling within industrial processes; or Equipment replacement or modifications. 11 Good Housekeeping Leads to Pride & Commitment Keep It Clean In the First Place Waste, Leaks & Spills Easier to Spot Dry Cleanup 12 Inventory Management Procurement Control Material Types & Quantities Container Sizes & Packaging Requirements Raw Material Quality MSDS’s Material Control Unloading & Storage Handling & Use 13 Source Reduction Options for Packaging Light weighting Selecting another material Bulk packaging Switching from single-use to reusable containers 14 Preferred Packaging Guidelines NO Packaging Minimal Packaging Consumable Returnable/Reusable Recyclable Packaging, Recycled Material 15 Returnable for Reuse 16 Packaging Designed for Ease of Breakdown & Reuse L’Oreal USA Florence, KY 17 Plastic Container, Strap & Sheet Recycling L’Oreal USA Florence, KY 18 Redesign Packaging for Reuse to Avoid Recycling 19 Parallel Paradigms TQM P2 Customer Satisfaction Stakeholder Satisfaction Continuous Improvement Continuous Reduction Mgmt. By Measurement Monitor Waste Maximize Productivity Minimize Waste Zero Defects Zero Emissions 20 The Future of Pollution Prevention (P2)... Environmental Management Systems (EMSs) “Environmental Management System ” 21 P2 &EMSs “Systems Approach” Prevent Waste: Involvement or Commitment Add Value: Fullfillment Expectations Exceed Expectations “Owner” Employees Supplier Process Customer “Delight” 22 P2 Sustainable Phases Payoff Big ROI Today What When Now OPERATIONS Smaller ROI Today EQUIPMENT/ (Future??) SYSTEMS Near-term Smallest Long-term ROI Today PRODUCTION (Future??) PROCESS 23 Waste Reduction Operation Phase Start Recognized Need Assessment & Trng. Good Housekeeping Waste Separation 0-6 months, Big Return on Investment Simple Recycling 24 Agency & Industry Management Strategies Objectives To meet regulatory requirements To be cost-effective To improve environmental quality To produce a quality product 25 Implementing Pollution Prevention (P2) In General Corporate Commitment Team selection In an IPP Municipality Agrees to & SUPPORTS P2 Activities of its Staff. IPP Staff, Industry & Business Personnel 26 Implementing P2 In General In an IPP Background Headworks Analysis Information Flow Diagram & Plant Survey Materials Balance Sewer Line Blueprints SIU Process Flow Diagrams Permit Applications Indirect Discharge Monitoring Reports Self-monitoring Reports 27 Implementing P2 Alternatives Analysis In The Past Present & Future Best Available Source Reduction Control Technology (BACT Treatment) Opportunities Reuse Potential Recycle Potential Energy Recovery Treatment (BACT) Disposal 28 Evaluate Why P2 is Important to Communities Water is a limited resource Statewide Water Quality - Once quantity is restricted, the quality must be monitored TMDL’s - Limits to what a watershed can receive P2 may be the first step to encourage nonpretreatment cities to reduce pollutant contributions 29 Incorporate P2 Language Restate the City’s environmental policy statements in City Ordinances, wastewater permits & permit applications Require P2 plans & best management practices (EMS) as part of all department’s goals 30 Source Reduction Training Manager Training Employee Training Process / Job / Shift EMS/Systems Approach Internal Assessment Show Corporate & Agency Commitment 31 42 Cubic Yard Compactor Boxes 15 - 22 Loads per Day 32 Closer View of Compactor Loads 33 ID Solid Waste Materials Cardboard Wood Plastics Polystyrene Office Paper 34 Compactor Box Load Total = 10,560 lbs. 35 Cardboard Separation Total = 2,940 lbs. (27.8%) Conveyor of Mixed Solid Wastes Cardboard Sorting by Hand Uncontaminated Cardboard is Baled 36 Solid Waste w/ Cardboard Removed = 7,620 lbs. (71.2%) 37 Wood Separation 38 Wood = 2,400 lbs. (22.7%) 39 Trash = 5,220 lbs. (49.4%) 40 Plastic in the Solid Waste Stream What types? $0.03/lb. Or $60/Ton 41 Reclaim,Recover & Reuse On-site Off-site Materials Exchange 42 Challenges to Recycling Cheaper to use virgin materials Recycled materials often fail to meet Buyer Specs Consumer mistrust of recycled materials Inadequate supply of Post-consumer materials 43 Kentucky Industrial Materials Exchange What is KIME? A database A matching service A way to reduce landfill volume A way for organizations to reduce waste disposal costs & raw material costs 44 Kentucky Industrial Materials Exchange 9% Miscellaneous 48% Hazardous •Acid •Solvent •Etc. Hazardous Non-Hazardous Miscellaneous 43% Non-Hazardous •Glass •Wood •Paper •Etc. 45 Types of Companies Using KIME Laboratory Electrical/ Computer 6% Plastic 7% Government Organizations 6% Wood/Furniture 30% Pigments/ Coating 10% Automotive Parts 5% Metal/Mineral 11% Environmental/ Recycling Rubber/Tire 16% Chemical 4% 4% 46 Waste Reduction Equipment Phase Process Controls Equipment Modifications Source Treatment 6 months - 2 years Some Return on Investment 47 General P2 Considerations Management Process & equipment selection Vehicle Maintenance Sludge management Construction methods & materials Laboratories Operational Control & Maintenance 48 Equipment Maintenance & Preventive Maintenance Routine Inspections Proper setup & adjustment Repairing Leaks Immediately Replace Parts Before Expected Failure Reduce Unexpected Downtime Tracking Maintenance Operator training 49 P2 Process & Equipment Selection Considerations Solid Waste (Reduce/Reuse/Recycle) Energy demand (efficiency) Chemical use (disinfect, odors, aids) Air emissions (VOCs, aerosols) Water use & conservation Sludge generated (heavy metals, etc.) 50 Waste Reduction Process Phase Complex Recycling, Refining, Reuse Process Changes Raw Material and Catalyst Changes Product Reformulations 2 years - 5 years Little Return on Investment 51 Material Substitution Less-toxic, lower-emitting substitutes May effect process elsewhere May require equipment modifications 52 P2 Perspective: Minimization Reduce Materials Usage & Losses Reduce Toxics Use with Alternative Materials Reduce Water Usage Reduce Energy Usage 53 Business Perspective: Optimization Increase Market Share Improve Cash Flow Reduce Cycle Time Reduce Set-up Time Reduce Work In-Progress Reduce Defect & Reject rate Improve Flexibility of Manufacturing Reduce Production Bottlenecks 54 Integrating P2 into Existing Programs Productivity Enhancement Quality Management Systems Preventive Maintenance Operation Automation Inventory Control (JIT) Product Development Computer Integrated Mfg. Employee Health & Safety Environmental Management 55 P2 Program Paradigm Shift Old Paradigm: “Doers” Investigation & Implementation Creates pollution prevention programs Creates new channels of communication Implements existing opportunities Focuses on information transfer Modifies existing activities Seeks to create awareness Builds upon trust New Paradigm: “Finishers” Long-term Organizational Change Integrates P2 w/ existing programs Co-opts existing channels of communication Prepares for new opportunities Focuses on information analysis Modifies existing contexts Seeks to move to action Builds on credibility 56 Integrated P2 Assessment EMS Audit An expanded assessment…EMS Gap Audit Examining: Business Systems Business Practices Overall Manufacturing Context So that: P2 strategies are tailored to the organization’s objectives & targets P2 is implemented with EMPs 57 Senior Management Track Investigate: Business goals & policies Management perspectives on current operations Decision-making methods Amounts & types of planning Organizational structure To Determine: Expressions & amount of management commitment Management triggers & priorities Sacred Cows--What P2 must be respectful of! Who holds key power & influences positions 58 Production/Activities Management Track Investigate: Purchasing & procurement methods Production scheduling methods Inventory control systems Relationships with suppliers/quality assurance To Determine: Opportunities for P2 through production control improvements Opportunities to link P2 to existing production management changes Possible coordination with buyers/suppliers 59 Support Functions/Services Track Investigate: Cost accounting/overhead allocation systems Capital budgeting process Training Programs Compensation & incentive programs Environmental data gathering & management Quality improvement programs, methods & tools To Determine: Total environmental management costs Amount & quality of resources available for P2 planning Ways to integrate P2 into quality improvement efforts 60 Impediments to Success Emphasis on Process Inadequate Training Lack of Planning Poor Communications Lack of Patience Assign to Person, Not a Team Treating as a Special Program 61 Institutional Barriers Supply Practices Materials Usage Patterns Materials Management Practices Waste Disposal Practices Resource Consumption Patterns Preferential Use of Equipment or Techniques 62 www.kppc.org The Next Steps: P2 & EMSs Clearwater, FL June 7, 2000 Cam Metcalf Executive Director jcmetc01@gwise.louisville.edu 502-852-0965 63