Understanding the Supply Chain

advertisement

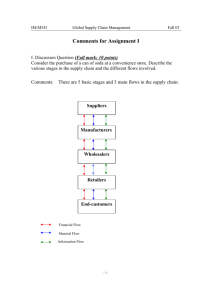

Supply Chain Management Lecture 2 Announcements • Summer Intern Program at Ball Aerospace – 10 week summer program that provides candidates with • Practical experience on relevant projects while working with designated mentors • A competitive salary • Access to state-of-the-art equipment • Possible future employment • Housing assistance • Relocation reimbursement • In-house training • Group activities – For more information visit • http://www.recruitingsite.com/csbsites/ball_aerospace/JobDescription. asp?JobNumber=617603 • http://www.ballaerospace.com/ Outline • Last Tuesday – Chapter 1 • Sections 1, 2 • Today – Chapter 1 • Sections 3, 4, 5 • Next week – Chapters 2 and 3 What is a Supply Chain? • Flow of products and services from – – – – – – – Suppliers Raw materials manufacturers Intermediate goods manufacturers Finished goods manufacturers Distributors and wholesalers Retailers Customers • Connected through transportation, information, and exchanges of funds Supplier Manufacturer Distributor Retailer Customer Key Observations • In order to maximize supply chain surplus – Every facility that impacts costs needs to be considered • Suppliers’ suppliers • Customers’ customers – Efficiency throughout the supply chain network is required using a network level approach What is Supply Chain Management? Supply chain management involves the management of supply chain assets and products, information, and fund flows to maximize total supply chain surplus What is Supply Chain Management? Getting the right things to the right places at the right times for profit What is Supply Chain Management? • “Managing supply and demand, sourcing raw materials and parts, manufacturing and assembly, warehousing and inventory tracking, order entry and order management, distribution across all channels, and delivery to the customer” – The Supply Chain Council • “The design and management of seamless, value-added process across organizational boundaries to meet the real needs of the end customer” – Institute for Supply Management What is Supply Chain Management? • “Supply chain management is a set of approaches utilized to efficiently integrate suppliers, manufacturers, warehouses, and stores, so that merchandise is produced and distributed at the right quantities, to the right locations, and at the right time, in order to minimize system wide costs while satisfying service level requirements” – Simchi-Levi et al, 2003 • Video – Ford Manufacturing Supply Chain What is Supply Chain Management? • Supply chain management is all about relationships – Management of relationships in order to enhance value and reduce cost – Collaboration is an important part of effective supply chain management Evolution of Supply Chain Management Further Refinement of SCM Capabilities SCM Formation/ Extensions JIT, TQM, BPR, Alliances Inventory Management/Cost Optimization Traditional Mass Manufacturing 1950s 1960s 1970s 1980s 1990s 2000s Beyond Evolution of Supply Chain Management • Mass production era (1900s – 1970s) – In the early 1900s, Henry Ford created the first moving assembly line reducing the time to build a Model T from 728 hours to 1.5 hours • Lean manufacturing era (1970s –1995) – In the early 1970s, Japanese manufacturers like Toyota changed the rules of production from mass to lean. Lean manufacturing focuses on flexibility and quality more than on efficiency and quantity. • Mass customization era (1995 – 2010?) – Beginning around 1995 and coinciding with the commercial application of the Internet, manufacturers started to mass-produce customized products. Henry Ford’s famous statement “You can have any color Model T as long as it’s black” no longer applies. Managing a Supply Chain is Not Easy • • • • Geographically dispersed complex network Conflicting objectives across the supply chain Uncertainty and risk factors Information distortion Managing a Supply Chain is Not Easy • Geographically dispersed complex network Managing a Supply Chain is Not Easy • Conflicting objectives across the supply chain Manufacturer • Large production batches Distributor • Low inventory • Few DCs Retailer • • • • Few stores Low inventory Little variety Close to DCs • Large shipments Customer • Convenience • Short lead time • Large variety of products Managing a Supply Chain is Not Easy • Uncertainty and risk factors – 2005 Hurricane Katrina • P&G coffee supplies from sites around New Orleans • Six month impact – 2002 West Coast port strike • Losses of $1B/day • Store stock-outs, factory shutdowns – 2001 India earthquake • Supply interruptions for apparel manufacturers – 1999 Taiwan earthquake • Supply interruptions for HP and Dell Managing a Supply Chain is Not Easy • Information distortion Supplier Manufacturer Distributor Bullwhip effect Retailer Customer Why Study Supply Chain Management? The Magnitude • In 1998, American companies spent $898 billion in supply chain related activities (or 10.6% of Gross Domestic Product) • Third party logistics services grew in 1998 by 15% to nearly $40 billion • It is estimated that the grocery industry could save $30 billion (10% of operating cost) by using more effective logistics strategies – A typical box of cereal spends more than three months getting from factory to supermarket The Potential • In 10 years, Wal-Mart transformed itself by changing its logistics system. It has the highest sales per square foot, inventory turnover and operating profit of any discount retailer • Laura Ashley turns its inventory 10 times a year, five times faster than three years ago – New information system – Centralized warehouse The Impact In 1996, Dell held 31 days of inventory. It now holds only 4 days of inventory. The Impact The Impact • The Turning Point (The Economist, 9/20/07) – “For such a tiny part of GDP, the contents of warehouses has had a surprisingly big effect on its volatility. When industries cut or add stocks according to demand, that adjustment magnifies the effect of the initial change in sales. Stock levels were once much larger relative to the size of the economy, so a small slip in demand could easily blow up into a recession. But thanks to improvements in technology, firms now have timelier and better information about buyers. Speedier market intelligence and production in smaller batches allows firms to match supply to changing conditions. This makes huge stocks unnecessary and minimizes the lurches in inventories that were once so destabilizing. The entire inventory of some lean-running companies now consists of whatever FedEx or UPS is shipping on their account. Mr Cecchetti and his colleagues calculate that, on average, more than half the improvement in the stability of economic growth in the countries they studied is accounted for by diminished inventory cycles. That something so workaday as supply-chain management could have so marked an effect might seem a dull conclusion. But dullness is a virtue, because technological improvement is irreversible” The Impact Study of Supply Chain Management • Successful supply chain management requires decisions on the flow of information, product, and funds that fall into three decision phases – Supply chain strategy or design – Supply chain planning – Supply chain operation Decision Phases in a Supply Chain TIME FRAME years 3 mo.- 1year daily TYPE Strategic TYPICAL DECISIONS •Supply chain network design (How many plants? Location and capacities of plants and warehouses?) •Supply chain strategies (Sell direct or through retailers? Outsource or in-house? Focus on cost or customer service?) •Product mix at each plant Tactical •Workforce & Production planning •Inventory policies (safety stock level) •Which locations supply which markets •Transportation strategies Operational •Production scheduling •Decisions regarding individual orders •Place replenishment orders Study of Supply Chain Management • A supply chain is a sequence of processes and flows that take place within and between different stages – Cycle view • The processes in a supply chain are divided into a series of cycles, each performed at the interface between two successive stages of a supply chain – Push/pull view • The processes in a supply chain are divided into two categories depending on whether they are executed in response or in anticipation of a customer order Cycle View of Supply Chain Processes Customer Customer Order Cycle Cycle view defines the processes involved and the owner of each process Retailer Replenishment Cycle Distributor Manufacturing Cycle Manufacturer Procurement Cycle Supplier Subprocesses in Each Cycle Buyer Supplier markets the product Buyer may return the product Buyer places an order Buyer receives the order Supplier receives the order Supplier supplies the order Supplier Cycle View of Supply Chain Processes Customer Order Process 1. Customer Arrival Customer Order Cycle 2. Customer Order Entry 3. Customer Order Fullfillment 4. Customer Order Receiving Replenishment Cycle Manufacturing Process 1. Order Arrival 2. Production Scheduling 3. Manufacturing/Shipping 4. Receiving Replenishment Process 1. Retail Order Trigger 2. Retail Order Entry 3. Retail Order Fullfillment 4. Retail Order Receiving Manufacturing Cycle Procurement Cycle Procurement Process 1. Component Order Arrival 2. Production Scheduling 3. Manufacturing/Shipping 4. Receiving Push/Pull View of Supply Chain Processes PULL PROCESSES Execution is initiated in response to customer orders (reactive) Customer order arrives PUSH PROCESSES Execution is initiated in anticipation of customer orders (speculative) Processes are divided based on the timing of their execution relative to a customer order Push/Pull Processes for the Supply chain of Dell PULL Customer Customer Order Cycle and Manufacturing Cycle Manufacturer Procurement Cycle PUSH Supplier Push/Pull Processes for the Supply chain of Detergent Customer PULL Customer Order Cycle Retailer Replenishment Cycle Distributor PUSH Manufacturing Cycle Manufacturer Procurement Cycle Supplier Are the following systems push or pull? Soda vending machines Amazon.com Emergency care Paint industry Runway capacity at an Airport Cycle View Versus Push/Pull View Which view is more useful when considering operational decisions and which view is more useful when considering strategic decisions? Examples of Supply Chains Celestial Seasonings • The herbs were originally harvested by hand in the Rocky Mountains • Currently, herbs and leafs come from growers around the world – “We’ve been working to establish sustainable harvests and fair wages for more than 30 years” What are advantages of having one production facility? What are disadvantages of having one production facility? What advantages does selling tea over the Internet provide?