SFI Norman Organisasjon og ledelse

advertisement

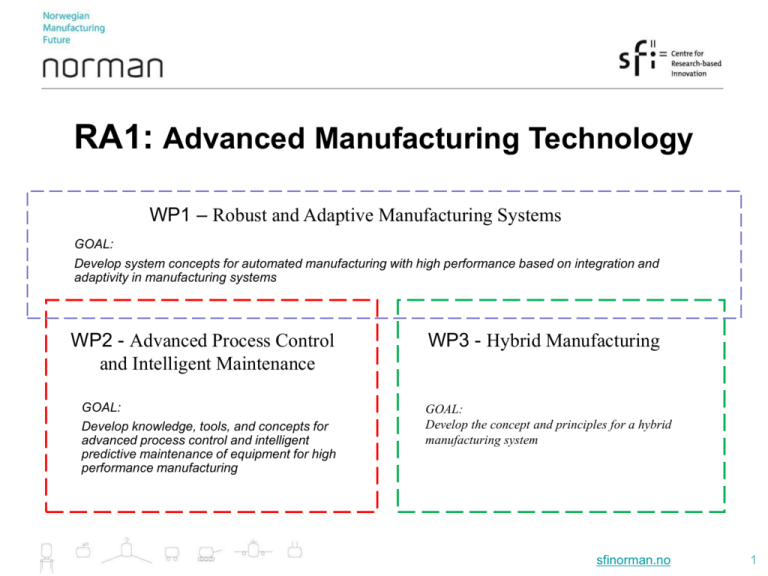

RA1: Advanced Manufacturing Technology WP1 – Robust and Adaptive Manufacturing Systems GOAL: Develop system concepts for automated manufacturing with high performance based on integration and adaptivity in manufacturing systems WP2 - Advanced Process Control and Intelligent Maintenance GOAL: Develop knowledge, tools, and concepts for advanced process control and intelligent predictive maintenance of equipment for high performance manufacturing WP3 - Hybrid Manufacturing GOAL: Develop the concept and principles for a hybrid manufacturing system sfinorman.no 1 Collaboration between WPs Research area 1: Advanced Manufacturing Technology WP5 T3 Work Organization T5 WP1 - Robust and Adaptive Manufacturing Systems WP2 - Advanced Process Control and Intelligent Maintenance WP3 - Hybrid Manufacturing WP4 T2 Planning and Control T4 WP6 sfinorman.no 2 PhD involvement WP1 T1: T2: T3: T4: WP2 T1: T2: T3: T4: T5: WP3 T1: T2: T3: Robust and Adaptive Manufacturing Systems Implications of the concept of the constantly changing manufacturing system for: Study new design methods for manufacturing control based on an agent-oriented bottom-up approach Develop and integrate new agent-oriented design tools in the APROX framework Define operator information and control requirements in highly automated manufacturing environments - work organization and demand for skill development Define handling characteristics for non-rigid materials Advanced Process Control and Predictive Maintenance Sensor and sensor system development and integration for measurement of critical process parameters Control strategies and methods for self-adjusting, -calibrating and -reconfigurable processes Fault diagnosis and prognosis system for preventive maintenance of production equipment 3D-object measurement and inspection on the basis of 3D point clouds Operator decision-support: strategies, models and tools for effective problem solving based on a combination of operator/specialist knowledge and monitoring of measured or estimated process parameters Hybrid manufacturing Development of a hybrid manufacturing cell by integration of additive manufacturing with conventional CNC milling Case studies: principles for enhanced tooling capability and high performance parts by incorporation of complex geometries and variable material composition for advanced thermal management and directed part material properties Design for performance: design principles to exploit the possibilities of the Hybrid Manufacturing concept Task in all WP's: International collaboration and network building sfinorman.no 3 PhD involvement WP1 T1: T2: T3: T4: WP2 T1: T2: T3: T4: T5: WP3 T1: T2: T3: Robust and Adaptive Manufacturing Systems Implications of the concept of the constantly changing manufacturing system for: New design methods: symbolic communication between machines/devices. For such communication, both software and hardware of present equipment must be extended. Develop and integrate new agent-oriented design tools: systems, e.g. assembly systems, capable to work in not well structured environment. - work organization and demand for skill development Define handling characteristics for non-rigid materials Advanced Process Control and Predictive Maintenance Sensor and sensor system development and integration for measurement of critical process parameters: Sensor networks capable of acquiring symbolic data Control strategies and methods for self-adjusting, -calibrating and -reconfigurable processes: strategies and methods based on symbolic data mining and optimization. Solutions imitating biological reflexes Fault diagnosis and prognosis system for preventive maintenance of production equipment 3D-object measurement and inspection on the basis of 3D point clouds Operator decision-support: strategies, models and tools for effective problem solving based on a combination of operator/specialist knowledge and monitoring of measured or estimated process parameters: HMI communicating with operators on the symbolic level Hybrid manufacturing Development of a hybrid manufacturing cell by integration of additive manufacturing with conventional CNC milling Case studies: principles for enhanced tooling capability and high performance parts by incorporation of complex geometries and variable material composition for advanced thermal management and directed part material properties Design for performance: design principles to exploit the possibilities of the Hybrid Manufacturing concept sfinorman.no 4 Results from RA1 WP1 Robust and Adaptive Manufacturing Systems Control logic verification Before Now Programming logic in QUEST* syntax Programming logic in target language** syntax 'Verified' control logic Truly verified control logic in real equipment environment *QUEST simulation software **Python sfinorman.no 5 Results from RA1 WP1 Robust and Adaptive Manufacturing Systems Now Control logic verification Programming logic in target language** syntax Truly verified control logic in emulated equipment environment Switching to real equipment environment sfinorman.no 6 Results from RA 1 WP2 Advanced Process Control and Predictive Maintenance 1. Flexible, automated sewing further developed: + A software has been developed for integration of control of robot, PyMoCo and ROS + Real time control has been tested and promising results have been achieved for 8 milliseconds control. + A new speed sensor (mechanics and electronics) has been developed. The sensor will be used for measurements required for further development of the control system for the sewing cell. = Sew together parts of different shapes and materials, without prior knowledge of the part geometries 2. A predictive maintenance model has been established in order to obtain optimal maintenance scheduling based on the condition of the equipment. 3. RFID techniques in condition monitoring has been researched, and a demo of RFID application in production system has been established. 4. A dual arm robot installation is being built sfinorman.no 7 Results from RA 1 WP3 Hybrid Manufacturing 1. A new method for preparing the substrates for additive manufacturing in a CNC milling machine has been developed. 2. The cohesion of the AM section to the base part has been tested with excellent results (Marlok C1650+ CL 50WS AM tool steel). 3. Porous sections built into the tool insert derived as a valuable complement to other practical solutions 4. A prototype integrated control system for the hybrid cell (OMOS) has been further developed, in collaboration with exchange student from Slovenia. 5. A prototype of the hybrid cell control system has been developed. sfinorman.no 8 Other results New projects: • Autoflex - Flexible automated manufacturing of large and complex products: Partners: RollsRoyce Marine AS, Benteler Aluminium Systems Norway AS, Intek Engineering AS, SINTEF Raufoss Manufacturing AS and NTNU. • SmartTools: Partners: Sandvik Teeness AS, SINTEF ICT, SINTEF Raufoss Manufacturing and NTNU IPK Contribution to education: • The Framework of IFDPS becomes a part of a course (TPK 4155 Applied Computational Intelligence in Intelligent Manufacturing) • The RFID application demo for Production System becomes a practice study for a course called PK8106 Knowledge Discovery and Data Mining sfinorman.no 9 International collaboration within RA1 in 2012: Chairman from Industry for Joining Sub-Platform: SFI Norman and SINTEF Raufoss Manufacturing AS have worked actively in Manufuture by participating in the HLG. As a result Kristian Martinsen now holds the chair, as an industry representative, for the new sub-platform for Joining. Exchange agreement with four students from Ensiame Engineering School, Valenciennes, France. Have been working on design of a flexible jig for assembly of components for Sandvik Teeness and a dual arm robot installation. Collaboration through the development of the new ISO standard on additive manufacturing technology does now include the chair for ISO/TC261 WG1 Terminology for additive manufacturing. DTI (Denmark), VTT (Finland), Acreo (Sweden), Fraunhofer (Germany): collaboration on coatings, integrated sensors and new business models for injection molding industry. Two new EU-projects have been granted, SASAM and Diginova, where SINTEF Raufoss Manufacturing is a partner. Diginova, short for Innovation for Digital Fabrication, is a coordination and support action project under NMP 7th FP, Networking of materials laboratories and innovation. SASAM, which is short for Support Action for Standardisation in Additive Manufacturing, is a similar type of project. Collaboration on a EU-proposal "VITAMIN", where Sandvik Teeness was partner together with SRM and SINTEF ICT from Norway. Not granted. sfinorman.no 10 Planned international collaboration within RA1 for 2013: Polytechnic Institute of Braganca, Portugal: • Prof. Paulo Leitaõ: workshop around holonic manufacturing, common publication or similar. The University of Manchester, UK: Dr. Yi Wang: • • establishing projects on Intelligent systems and Predictive Maintenance. Common publication: a book on data mining for zero-defect manufacturing VTT Technical Research Centre of Finland, +rest of consortium • EU proposal for call FoF.NMP.2013-7 "New hybrid production systems in advanced factory environments based on new human-robot interactive cooperation": University of Ljubljana: • Prof. Slavko Dolinsek and student David Homar, continue collaboration on development on OMOS (Optimized Manufacturing Operation Sequence) University of Berlin (???? ): • Prof. Günther Seliger: workshop around flexible automation and possibly researcher exchange? sfinorman.no 11 More detailed on results sfinorman.no 12 Some results from RA1 Substrate preparation • Flat milling produces a glossy surface; – Low-friction for powder spreading – Reflective to laser beam • Standard procedure: Sand blasting, -unsuitable for the hybrid cell • Hybrid cell procedure: Extra sharp cutting tool inserts "scratch" the substrate – Provides an exact z = 0 -point for starting the AM building • Edge radius: 0 – 0.1 mm; • Cutting depth: 0.1 mm; • Feed rate: 0.05 mm/O sfinorman.no 13 OMOS: Optimized Manufacturing Operation Sequence sfinorman.no 14 Some results from RA1 WP3: Industrial case studies: insert for a bracket to an office chair Results: • Cooling time for conventional insert and “old” design 70 sec. – Estimated cooling time with new design approximately +25 sec. = 95 sec. • Cooling time with new design and conformal cooling insert: 48 sec. • Cost of machining AM produced insert similar to conventional production, however the cost of AM makes this an expensive insert Industrial need: reduced cost of production by AM closer to final shape sfinorman.no 15 Demonstrator development Working principle: sfinorman.no 16 Demonstrator development Example: System Frame of IFDPS – Intelligent Fault Diagnosis and Prognosis System Degradation Process Equipment or Process Maintenance Scheduling / Maintenance Optimization Information Delivery Fault Prognosis Bee Colony Algorithms (BCA) Auto-regressive Moving Averaging (ARMA) Ant Colony Optimization (ACO) Fuzzy Logic Prediction Particle Swarm Optimization (PSO) ANN Prediction Gentic Algorithms (GA) Match Matrix Prediction Meta-Heuristic approaches Fault Diagnosis Support Support Machine (SVM) Sensors (Data Acquisition) Signal Pre-process Feature Extraction Denosing Time Domain Compression Time-Frequency Domain Extract Weak Signal Frequency Domain (FFT, DFT) Filter Wavelet Domain (WT, WPT) Amplification Principal Component Analysis (PCA) Data Mining (Decision Tree & Association rules) Artificial Neural Network (SOM & SBP) Statistical Maching sfinorman.no 17