The Distribution Game - Transportation Careers

advertisement

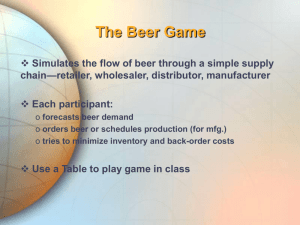

The Distribution Game Modified from the MIT game The Distribution Game • This game originated from MIT’s “Beer Game.” • It was created to demonstrate the “Bullwhip Effect” and how shared information can created a more efficient and effective supply chain. • It also illustrates the basis of Supply Chain Management and its principles. – How single parts of the supply chain influence each other – How individual thinking differs from systematic or network thinking – Potential for system optimization and the use of information systems. Supply Chain Board Setup • Competitive-Cooperative Game with limits on Cooperation • Each team will compete against each other Orders Going Upstream Manufacturer 2 Week Delay Distributor 2 Week Delay Wholesaler Product Going Downstream 2 Week Delay Retailer Objectives and Rules of the Game • You and your fellow classmates will try to run the most efficient and effective supply chain by minimizing inventory and stockout costs. • Each student or team will take on of the following roles: – – – – Manufacturer Distributor Wholesaler Retailer • You cannot talk or communicate with the rest of the supply chain. Objectives and Rules of the Game • You cannot look ahead at orders. • Each turn = 1 week • Shipping and order delays are 2 weeks long – This is know in industry as “lead time.” • Every order must be fulfilled. The orders never cancel out and are good until fulfilled. • Each team/student will follow the instructor’s lead for each week. Steps The following steps will be repeated each turn or week 1.Receive the shipment of product from upstream and place it into your inventory 2.Receive the order from downstream and fulfill the order by shipping the appropriate number of products downstream. 3.Record your inventory or backlog for the week on the given sheet 4.Place your order upstream. The week is then completed! Costs • The lowest cumulative cost wins • Costs will be calculated according to the following rules: – Costs: are cumulative over time • Each unit of inventory costs $.50 per week • Each unit of Backlog costs $1.00 per week – Backlog: an order that cannot be fulfilled when it is received. – Backlogs will be calculated the following way: Last week’s backlog + New orders = Orders to Fill Orders to Fill – Amount Shipped = Current week’s backlog Costs – Each team/student will be responsible for keeping track of costs from week to week. – Each team/student will be responsible for charting customer orders and inventory/backlogs from week to week. – Forms will be given to help with these activities and will be collected at the end of the game. • Start the Game Simulation! • HOW DID YOU DO??? General Observations • • • • What did you think about the other entities in the supply chain Did they show great skill? Did they have your interest at heart? Did they show disregard for your needs? • General Observations: – Performance tends to be poor – Similar patterns always occur – Lack of communication can cause frustration between supply chain partners. Improvement in the Supply Chain through better Management • • • • How could you improve information flows? How could you improve forecasting? Is it feasible to eliminate the wholesaler and distributor? How could you improve order policies?