T3-OL14 Marina V. Bukhtiyarova, Carlos A. Carrero Marquez

advertisement

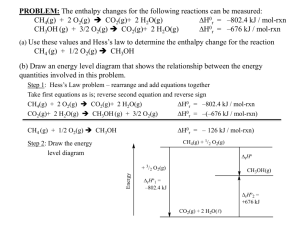

MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION METHANOL SYNTHESIS ON COPPER-BASED CATALYSTS M.V. Bukhtiyarova MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION Introduction 1. Methanol production is a large industrial process. 2. Methanol is produced using synthesis gas at 250°C and 50 – 100 bars CO + 2H2 = CH3OH Catalyst: Cu/ZnO/Al2O3 3. High emission of CO2 resulted in studying methanol synthesis through CO2 hydrogenation. 4. Methanol can be viewed as a way of hydrogen storage Methanol synthesis MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION CO2 + 3H2 CH3OH +H2O Methanol synthesis setup Gas mixture: H2:CO2 = 3:1 Pressure: 30 and 50 bars Temperature: 190, 210, 230, 250 and 260°C GHSV: 4800 and 7200 h-1 Süd-Chemie catalyst : Cu/ZnO/Al2O3 (old generation) Gas chromatography of liquid sample MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION Sample obtained at 250°C, 30 bar, 7200 h-1 Samples are dissolved in acetone to have reproducible results 400 Wasser #87 [modified by gschmitz] pA 300 TCD air RSG-MS-017-13 Methylformiat 3 50 1 acetone 100 1 - 68 [modified by gschmitz] 100 2 - 62 pA 75 1 200 Reference methylformate solution contains 5% of methanol 2 2 Reference methylformate 25 2 1 2 Sample 1 -5 0,00 min 1,00 2,00 No. Ret.Time Peak Name min 1 2.50Methanol 2 3.31Wasser 3,00 4,00 Rel.Area % 48.277 51.723 5,00 -10 0,00 min 1,00 2,00 No. Ret.Time min 1 1.69 2 2.02 3 2.98 3,00 4,00 Peak Name 5,00 6,00 Rel.Area % Methyl formate 0.014 n.a. 0.015 Methanol 99.970 Traces of methylformate are observed during methanol synthesis 7,00 Methanol synthesis 1.4 30 Ratio CH3OH/H2O, ml/ml 40 Volume, ml MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION 50 CH3OH H2O GHSV = 4800 h -1 260°C p = 30 bar 250°C 20 230°C 210°C 10 190°C 0 6 9 12 15 18 21 24 27 30 190°C 210°C 1.2 -1 GHSV = 4800 h 1.0 p = 30 bar 250°C 260°C 0.8 6 9 CO2 + 3H2 12 15 18 Time, h Time, h Methanol synthesis: CH3OH +H2O H = – 49.7 kJ/mol 230°C Reverse water gas shift: CO2 + H2 CO +H2O H = 41.2 kJ/mol Ratio of CH3OH/H2O (ml/ml) = 2.24 Increasing temperature promotes water-gas shift reaction 21 24 Dependence on pressure 50 50 30 CH3OH H2O GHSV = 4800 h 40 -1 260°C p = 30 bar Volume, ml 40 Volume, ml MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION Methanol synthesis 250°C 20 230°C 210°C 10 30 CH3OH H2O GHSV = 4800 h -1 260°C 250°C p = 50 bar 230°C 20 210°C 10 190°C 190°C 0 0 6 9 12 15 18 21 24 27 30 6 9 12 15 18 21 24 27 Time, h Time, h MS: RWGS: CO2 + 3H2 CH3OH +H2O CO2 + H2 CO +H2O According to Chatelier’s principle increase of pressure results in higher methanol formation 30 Dependence on space velocity 50 30 50 CH3OH H2O GHSV = 4800 h CH3OH H2O 40 -1 260°C p = 30 bar Volume, ml 40 Volume, ml MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION Methanol synthesis 250°C 20 230°C 10 210°C 30 260°C GHSV = 7200 h p = 30 bar -1 250°C 20 230°C 10 210°C 190°C 190°C 0 6 9 12 15 18 Time, h 21 24 27 30 0 6 9 12 15 18 21 24 Time, h Volume of formed methanol and water depends on reaction conditions 27 30 Dependence on space velocity at high pressure 50 50 30 CH3OH H2O GHSV = 4800 h 40 -1 260°C 250°C p = 50 bar Volume, ml 40 Volume, ml MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION Methanol synthesis 230°C 20 210°C 10 0 9 12 15 18 Time, h 21 24 27 260°C 250°C GHSV = 7200 h -1 p = 50 bar 230°C 20 210°C 10 190°C 6 30 CH3OH H2O 30 190°C 0 6 9 12 15 18 21 Time, h Volume of methanol and water does not practically change at temperature higher than 250°C 24 27 30 Dependence on pressure GHSV = 4800 h-1 Dependence on space velocity p = 30 bar 20 16 18 -1 14 12 10 8 6 4 2 0 453 463 473 30 bar 50 bar 14 4800 h -1 6000 h -1 7200 h 16 CO2 conversion, % CO2 conversion, % MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION CO2 conversion 483 493 503 513 Temperature, K 523 533 543 12 10 8 6 4 2 0 453 463 473 483 493 503 513 523 533 Temperature, °C Conversion of CO2 increase with temperature and decrease with space velocity 543 Dependence on pressure GHSV = 4800 h-1 Dependence on space velocity p = 30 bar 80 80 70 70 Selectivity CH3OH, % Selectivity CH3OH, % MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION Methanol selectivity 60 50 40 -1 4800 h -1 6000 h -1 7200 h 30 20 10 0 453 463 473 483 493 503 513 Temperature, K 523 533 543 60 50 40 30 bar 50 bar 30 20 10 0 453 463 473 483 493 503 513 Temperature, K At high pressure selectivity practically does not change with temperature 523 533 543 Dependence on space velocity p = 30 bar Dependence on pressure GHSV = 4800 h-1 8 8 7 7 -1 4800 h -1 6000 h -1 7200 h 6 5 Yield CH3OH, % Yield CH3OH, % MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION Methanol yield 4 3 2 1 30 bar 50 bar 6 5 4 3 2 1 0 453 463 473 483 493 503 513 Temperature, K 523 533 543 0 453 463 473 483 493 503 513 523 533 543 Temperature, °C Methanol yield increases with temperature, pressure and decreases with space velocity Comparison with literature data -1 0,0 4800 h -1 6000 h -1 7200 h Ea = 48.7 kJ/mol -0,5 Ea = 48.2 kJ/mol Ea = 44.9 kJ/mol -1,0 -1,5 -2,0 1,85 1,90 1,95 2,00 2,05 1/T, 1/K 2,10 2,15 2,20 Activation energy, kJ/mol 0,5 Ln(Rate(CH3OH)) MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION Activation energy 50 48 46 44 a Cu/ZnO/Al2O3 Cu/ZnO d a 42 40 38 Cu/ZnO/Al2O3/Cr2O3 b Cu/ZrO2 c (a) Our data (b) H. Arakawa, Energy Conv. Mgmt: 33 (1992) 521 (c) X. Guo, J. Mol. Catal. A: 345 (2011) 60 (d) A. Karelovic, Catal. Today: 197 (2012) 109 36 Obtained activation energy is in the agreement with activation energy presented in literature Conditions for stability test: H2:CO2 = 3:1; 30 bar, 230°C; 4800 h-1 10 8 Yield CH3OH, % MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION Methanol synthesis 6 4 2 0 0 50 100 150 200 250 300 350 400 450 Time, h Productivity of methanol decreases during first 100 after that the catalyst works stable for another 300 hours Methanol synthesis CO2 + 3H2 CH3OH +H2O Gas mixture: H2:CO2 = 3:1 Pressure: 30 bar Temperature: 190, 210, 230, 250 and 260°C GHSV: 4800 h-1 Clariant (Süd-Chemie) catalysts Old Catalyst New Catalyst 65 16 60 14 14 12 12 10 10 8 8 6 6 4 4 2 2 0 0 453 463 473 483 493 503 513 523 533 543 Temperature, K Selectivity CH3OH, % 16 18 Yield CH3OH, % 18 Conversion CO2, % MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION Methanol synthesis: Old Catalyst New Catalyst 55 50 45 40 35 30 25 453 463 473 483 493 503 513 523 533 543 Temperature, K The “old generation” catalyst works better for CO2 hydrogenation at low pressure MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION Conclusions 1. Methanol yield depends on reaction conditions: high pressure results in formation of higher amount of methanol 2. Practically pure methanol with trace amount of methylformate is produced 3. Clariant (Süd-Chemie) catalyst for methanol synthesis is stable during longterm experiment for 400 hours 4. Clariant (Süd-Chemie) catalyst of old generation is more suitable for production methanol by CO2 hydrogenation MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION THANK YOU FOR YOUR KIND ATTENTION Productivity CH3OH, kgMet/(kgcat*h) Productivity CH3OH, kgMet/(kgcat*h) MAX-PLANCK-INSTITUT FÜR CHEMISCHE ENERGIE KONVERSION Methanol yield -1 4800 h -1 6000 h -1 7200 h 453 463 473 483 493 503 513 Temperature, °C 523 533 543 30 bar 50 bar 453 463 473 483 493 503 513 Temperature, °C 523 533 543 Gas chromatography of liquid samples Instrument Column: Programm Method Report Agilent 6890 Stabilwax 30 m S-1 TCD 60 Wasser Rep Wasser Detektor Injector Tem.Programm Gas Split Injection Volume TCD 250°C 250°C 80°C He 0,93 bar 1 ml 1:20 0.5 µl Instrument Column: Programm Method Report 6890 Stabilwax 30m S-69 Stabilwax Pyrrol Rep normal Detektor Injector Tem.Programm: Gas: Split FID 300°C 240°C 50°C H2 0,86 bar 2,3 ml 1:20 Injection Volume: 0.5 µl The measurement using FID was done for determination organic impurities in methanol. FID does not detect water