Industrial Automation

advertisement

Industrial Automation

Automation Industrielle

Industrielle Automation

3

Industrial Communication Systems

3.2

Field bus operation

Buses de terreno: modo de trabajo

Bus de terrain: mode de travail

Feldbus: Arbeitsweise

Fieldbus - Operation

3.1 Field bus types

3.2 Field bus operation

Data distribution

Cyclic Operation

Event Driven Operation

Real-time communication model

Time distribution

Networking

3.3 Standard field busses

Industrial Automation

2013

Field Bus Operation 3.2 - 2

Objective of the field bus

Distribute process variables to all interested parties:

• source identification: requires a naming scheme

• accurate process value and units

• quality indication: {good, bad, substituted}

• time indication: how long ago was the value produced

• (description)

source

Industrial Automation

2013

value

quality

time

description

Field Bus Operation 3.2 - 3

Data format

source

value

quality

time

description

minimum

In principle, the bus could transmit the process variable in clear text (even using XML..)

However, this is quite expensive and only considered when the communication network

offers some 100 Mbit/s and a powerful processor is available to parse the message

More compact ways such as ASN.1 have been used in the past with 10 Mbit/s Ethernet

ASN.1: (TLV)

type

length

value

Field busses are slower (50kbit/s ..12 Mbits/s) and thus more compact encodings are used.

Industrial Automation

2013

Field Bus Operation 3.2 - 4

Datasets

Field busses devices have a low data rate and transmit always the same variables.

It is economical to group variables of a device in the same frame as a dataset.

A dataset is treated as a whole for communication and access.

A variable is identified within a dataset by its offset and its size

Variables may be of different types, types can be mixed.

dataset

binary variables

analog variables

dataset

identifier

wheel

speed

0

air

pressure

16

bit offset

Industrial Automation

2013

line

voltage

32

size

time

stamp

48

64 66

70

all door closed

lights on

heat on

air condition on

Field Bus Operation 3.2 - 5

Dataset extension and quality

To allow later extension, room is left in the datasets for additional variables.

Since the type of these future data is unknown, unused fields are filled with '1".

To signal that a variable is invalid, the producer overwrites the variable with "0".

Since both an "all 1" and an "all 0" word can be a meaningful combination, each

variable can be supervised by a check variable, of type ANTIVALENT2:

dataset

correct variable

error

undefined

variable value

check

0 1 0 1 1 1 0 0

0 1

0 0 0 0 0 0 0 0

0 0

1 1 1 1 1 1 1 1

1 1

chk_offset

var_offset

00 = network error

01 = ok

10 = substituted

11 = data undefined

A variable and its check variable are treated indivisibly when reading or writing

The check variable may be located anywhere in the same data set.

Industrial Automation

2013

Field Bus Operation 3.2 - 6

hierarchical or peer-to-peer communication

PLC

“master”

central master / slave: hierarchical

AP

alternate

master

PLC

AP

all traffic passes by the master (PLC);

adding an alternate master is difficult

(it must be both master and slave)

“slaves”

input

peer-to-peer: distributed

PLCs may exchange data,

share inputs and outputs

allows redundancy

and “distributed intelligence”

devices talk directly to each other

PLC

PLC

AP

Industrial Automation

2013

“masters”

AP

input

separate bus master from application master !

output

PLC

AP

“slaves”

output

AP

Application

Field Bus Operation 3.2 - 7

Broadcasts

A variable is read in 1..3 different places on avergage

Broadcasting messages identified by their source (or contents) increases efficiency.

application

processor

plant

image

application

processor

plant

image

…

application

processor

instances

…

plant

image

=

=

distributed variable

data base

plant

image

bus

Each device is subscribed as source or as sink for a number of process variables

Only one device is source of a certain process variable (otherwise collision)

The bus refreshes plant image in the background

The replicated traffic memories can be considered as "caches" of the plant state

(similar to caches in a multiprocessor system), representing part of the plant image.

Each station snoops the bus and reads the variables it is interested in.

Industrial Automation

2013

Field Bus Operation 3.2 - 8

Decoupling Application and Bus traffic

decoupled (asynchronous):

coupled (event-driven):

application

processor

application

processor

events

(interrupts)

traffic

memory

(buffer)

queues

bus

controller

sending: application writes data into memory

receiving: application reads data from memory

the bus controller decides when to transmit

bus and application are not synchronized

Industrial Automation

2013

bus

controller

sending: application inserts data into queue

and triggers transmission,

bus controller fetches data from queue

receiving: bus controller inserts data into queue

and interrupts application to fetch them,

application retrieves data

Field Bus Operation 3.2 - 9

Traffic Memory: implementation

Bus and Application are decoupled by shared memory, the Traffic Memory, (content

addressed memory, CAM, also known as communication memory); process

variables are directly accessible by application.

Application

Processor

Traffic Memory

Ports (holding a dataset)

Associative

memory

an associative memory decodes

the addresses of the subscribed

datasets

Bus

Controller

two pages ensure that read and

write can occur at the same time

(no semaphores !)

bus

Industrial Automation

2013

Field Bus Operation 3.2 - 10

Freshness supervision

Applications tolerate an occasional loss of data, but no stale data, which are at best

useless and at worst dangerous.

Data must be checked if they are up-to-date, independently of a time-stamp (simple

devices do not have time-stamping)

To protect the application from using obsolete data, each port in the traffic

memory contains a freshness counter.

This counter is reset by the bus or the application writing to that port. It is incremented

regularly, either by the application processor or by the bus controller.

The application should always read the value of the counter before using

the port data and compare it with its tolerance level.

The freshness supervision is evaluated by each reader independently, some readers may

be more tolerant than others. Bus error interrupts in case of severe disturbances are not

directed to the application, but to the device management.

Industrial Automation

2013

Field Bus Operation 3.2 - 11

Example of Process Variable application interface (program)

Access of the application to variables in a traffic memory is simple:

ap_put (variable_name, variable value)

ap_get (variable_name, variable value, variable_status, variable_freshness)

Rather than fetch and store individual variables, access is done by clusters

(predefined groups of variables):

ap_put_cluster (cluster_name)

ap_get (cluster_name)

The cluster is a table containing the names and values of several variables.

The clusters can correspond to "segments" in the function block programming.

Note: Usually, only one variable is allowed to raise an interrupt when received:

the one carrying the current time (sent by the common clock)

Industrial Automation

2013

Field Bus Operation 3.2 - 12

Transmission principle

The previous operation modes made no assumption, how data are

transmitted.

The actual network can transmit data

•

cyclically (time-driven) or

•

on demand (event-driven),

•

or a combination of both.

Industrial Automation

2013

Field Bus Operation 3.2 - 13

Cyclic versus Event-Driven transmission

cyclic: send value strictly every xx milliseconds

individual

period

misses the peak

(Shannon-Nyquist!)

always the same,

why transmit ?

time

hysteresis

event-driven: send when value change by more than x% of range

how much hysteresis ?

- coarse (bad accuracy)

- fine (high frequency)

Industrial Automation

2013

limit update

frequency !,

limit hysteresis

nevertheless transmit:

- every xx as “I’m alive” sign

- when data is internally updated

- upon quality change (failure)

Field Bus Operation 3.2 - 14

Fieldbus: Cyclic Operation mode

3.1 Field bus types

Classes

Physical layer

3.2 Field bus operation

Data distribution

Cyclic Operation

Event Driven Operation

Real-time communication model

Time distribution

Networking

3.3 Standard field busses

Industrial Automation

2013

Field Bus Operation 3.2 - 15

Cyclic Data Transmission

address

Bus

Master

1

2

3

4

5

devices

(slaves)

6

Poll

List

plant

The master polls the addresses in a fixed sequence, according to its poll list.

Individual period

1

2

3

4

5

Individual period

6

1

2 3

4

5

N polls

6

1

2 3

4

5

6

time [ms]

RTD

address

10 µs/km

(i)

read transfer

data

(i)

address

(i+1)

time [µs]

The duration of each poll is the sum of

the transmission time of address and

data (bit-rate dependent)

and of the reply delay of the signals

(independent of bit-rate).

44 µs .. 296 µs

Industrial Automation

2013

Field Bus Operation 3.2 - 16

Round-trip delay of master-slave exchange

master

closest data sink

repeater

T_m

most remote data source

repeater

t_repeat

t_repeat

The

round-trip

delay limits

the extension

of the bus

propagation delay

(t_pd = 6 µs/km)

T_m

t_source

t_mm

t_ms

access delay

(t_repeat < 3 µs)

T_s

t_repeat

t_sm

T_m

distance

Industrial Automation

2013

Field Bus Operation 3.2 - 17

Cyclic operation principle

Data are transmitted at fixed intervals, whether they changed or not.

The delivery delay (refresh rate) is deterministic and constant.

The bus is under control of a central master (or distributed time-triggered algorithm).

No explicit error recovery needed since a fresh value will be transmitted in the next cycle.

Only states may be transmitted, not state changes.

Cycle time is limited by the product of the number of data transmitted and the

duration of each poll (e.g. 100 µs / point x 100 points => 10 ms)

To keep the poll time low, only small data items may be transmitted (< 256 bits)

The bus capacity must be configured beforehand.

Determinism gets lost if the cycles are modified at run-time.

Cyclic operation is used to transmit the state variables of the process.

These are called Process Data (or Periodic Data)

Industrial Automation

2013

Field Bus Operation 3.2 - 18

Source-Addressed Broadcast

Process Data are transmitted by source-addressed broadcast.

Phase1: The bus master broadcasts the identifier of a variable to be transmitted:

bus

master

device

device

sink

source

subscribed devices

sink

sink

devices

(slaves)

bus

variable identifier

Phase 2: The device that sources that variable responds with a slave frame

containing the value, all devices subscribed as sink receive that frame.

bus.

master

subscribed

device

subscribed

device

sink

source

subscribed devices

sink

sink

devices

(slaves)

bus

variable value

Industrial Automation

2013

Field Bus Operation 3.2 - 19

Optimizing Cyclic Operation

Problem: Cyclic operation uses a fixed portion of the bus's time

The poll period increases with the number of polled items

The response time slows down accordingly

Solution: introduce sub-cycles for less urgent periodic variables

that are a power of 2 multiple of the base period:

2 ms period

1

2

4a

8

16

1 4b

4 ms period

1

2

3

64

1

4a

time

1 ms period

(basic period)

1 ms

1 ms

group with

period 1 ms

The poll cycles should not be modified at run-time (non-determinism)

A device exports many process data (state variables) with different priorities.

If there is only one poll type per device, a device must be polled at the

frequency required by its highest-priority data.

To reduce bus load, the master polls the process data, not the devices

Industrial Automation

2013

Field Bus Operation 3.2 - 20

Cyclic Transmission and Application

cyclic

poll

cyclic

algorithms

cyclic

algorithms

cyclic

algorithms

cyclic

algorithms

application

1

application

2

application

3

application

4

bus

master

Periodic

List

source

port

Traffic

Memory

Ports

Ports

Ports

sink

port

bus

controller

bus

controller

Ports

sink

port

bus

controller

bus

controller

bus

controller

bus

port address

port data

The bus traffic and the application cycles are asynchronous to each other.

The bus master scans the identifiers at its own pace.

Bus and applications are decoupled by a shared memory, the traffic memory,

which acts as distributed database updated by the network.

Industrial Automation

2013

Field Bus Operation 3.2 - 21

Application Of Cyclic Bus

The principle of cyclic operation, combined with source-addressed broadcast, has

been adopted by most modern field busses

It is currently used for power plant control, rail vehicles, aircrafts, etc...

Deterministic behavior, at expense of reduced bandwidth and geographical extension.

The poll scan list located in the central master (which may be duplicated for

availability purposes) determines the behavior of the bus. It is configured for a

specific project by a single tool, which takes into account the applications’

requirements. This guarantees that no application can occupy more than its share of

the bus bandwidth and gives control to the project leader.

Industrial Automation

2013

Field Bus Operation 3.2 - 22

Example: delay requirement

publisher

application instance

device

subscribers application instances

device

device

applications

bus

bus instance

Worst-case delay for transmitting all time critical variables is the sum of:

Source application cycle time

8 ms

Individual period of the variable

16 ms

Sink application cycle time

8 ms

= 32 ms

Industrial Automation

2013

Field Bus Operation 3.2 - 23

Example: traffic pattern in a locomotive

% periodic time

occupancy is proportional to surface

total = 92%

number of devices: 37 ( including 2 bus administrators)

30 frames of 128 bits

65 frames of 64 bits

37 of 16 bits

18 of 32

49 frames of 256 bits

period

16 ms

Industrial Automation

2013

32 ms

64 ms

128 256

1024

Field Bus Operation 3.2 - 24

Fieldbus: Event-driven operation

3.1 Field bus types

3.2 Field bus operation

Data distribution

Cyclic Operation

Event Driven Operation

Real-time communication model

Time distribution

Networking

3.3 Standard field busses

Industrial Automation

2013

Field Bus Operation 3.2 - 25

Event-driven Operation

• Events cause a transmission only when an state change takes place.

• Bus load is very low on average, but peaks under exceptional situations

since transmissions are correlated by the process (christmas-tree effect).

Multi-master bus: uses write-only transfers

intelligent

stations

eventreporting

station

eventreporting

station

eventreporting

station

sensors/

actors

plant

Detection of an event is an intelligent process:

• Not every change of a variable is an event, even for binary variables.

• Often, a combination of changes builds an event.

• Only the application can decide what is an event, since only the application

programmer knows the meaning of the variables.

Industrial Automation

2013

Field Bus Operation 3.2 - 26

Bus interface for event-driven operation

application

filter

driver

Application

Processor

• Each transmission on bus causes an interrupt.

• Bus controller checks address and stores data in

message queues.

• Driver is responsible for removing messages of queue

memory and prevent overflow.

• Filter decides if message can be processed.

message (circular) queues

interrupt

Bus

Controller

bus

Industrial Automation

2013

Field Bus Operation 3.2 - 27

Response of Event-driven operation

Caller

Application

Transport

software

Bus

Transport

software

Called

Application

request

interrupt

indication

confirm

time

Since events can occur anytime on any device, stations communicate by

spontaneous transmission, leading to possible collisions

Interruption of server device at any instant can disrupt a time-critical task.

Buffering of events can cause unbounded delays

Gateways introduce additional uncertainties

Industrial Automation

2013

Field Bus Operation 3.2 - 28

Determinism and Medium Access In Busses

Although the moment an event occurs is not predictable, the bus

should transmit the event in a finite time to guarantee the reaction delay.

Events are necessarily announced spontaneously

The time required to transmit the event depends on the medium access

(arbitration) procedure of the bus.

Medium access control methods are either deterministic or not.

Non-deterministic

Collision

(CSMA/CA)

Industrial Automation

2013

Deterministic

Central master,

Token-passing (round-robin),

Binary bisection (collision with winner)

Field Bus Operation 3.2 - 29

Events and Determinism

Deterministic medium access is necessary to guarantee delivery time bound

but it is not sufficient since events messages are queued in the devices.

events

producers

& consumers

input and

output queues

bus

acknowledgements

data packets

The average delivery time depends on the length of the queues, on the bus

traffic and on the processing time at the destination.

Often, the applications influence the event delay much more than the bus does.

Real-time Control = Measurement + Transmission + Processing + Acting

Industrial Automation

2013

Field Bus Operation 3.2 - 30

Events Pros and Cons

In an event-driven control system, there is only a transmission or an operation

when an event occurs.

Advantages:

Can treat a large number of events – but not all at the same time

Supports a large number of stations

System idle under steady - state conditions

Better use of resources

Uses write-only transfers, suitable for LANs with long propagation delays

Suitable for standard (interrupt-driven) operating systems (Unix, Windows)

Drawbacks:

Requires intelligent stations (event building)

Needs shared access to resources (arbitration)

No upper limit to access time if some component is not deterministic

Response time difficult to estimate, requires analysis

Limited by congestion effects: process correlated events

A background cyclic operation is needed to check liveliness

Industrial Automation

2013

Field Bus Operation 3.2 - 31

Fieldbus: real-time communication model

3.1 Field bus types

3.2 Field bus operation

Centralized - Decentralized

Cyclic Operation

Event Driven Operation

Real-time communication model

Time distribution

Networking

3.3 Standard field busses

Industrial Automation

2013

Field Bus Operation 3.2 - 32

Mixed Data Traffic

Process Data

represent the state of the plant

Message Data

represent state changes of the plant

short and urgent data items

infrequent, sometimes long

messages reporting events, for:

• Users: set points, diagnostics, status

• System: initialisation, down-loading, ...

... motor current, axle speed, operator's

commands, emergency stops,...

-> Periodic Transmission

of Process Variables

-> Sporadic Transmission of

Process Variables and Messages

Since variables are refreshed periodically,

no retransmission protocol is needed to

recover from transmission error.

Since messages represent state

changes, a protocol must recover lost data in

case of transmission errors

basic period

basic period

event

time

sporadic

phase

Industrial Automation

2013

periodic

phase

sporadic

phase

periodic

phase

Field Bus Operation 3.2 - 33

Mixing Traffic is a configuration issue

Cyclic broadcast of source-addressed variables is the standard solution in field busses

for process control.

Cyclic transmission takes a large share of the bus bandwidth and should be reserved

for really critical variables.

The decision to declare a variable as cyclic or event-driven can be taken late in a

project, but cannot be changed on-the-fly in an operating device.

A message transmission scheme must exist alongside the cyclic transmission to carry

not-critical variables and long messages such as diagnostics or network management

An industrial communication system should provide both transmission kinds.

Industrial Automation

2013

Field Bus Operation 3.2 - 34

Real-Time communication stack

The real-time communication model uses two stacks, one for time-critical variables

and one for messages

time-critical

process variables

time-benign

messages

7

Application

6

Presentation

Remote Procedure Call

5

Session

connection-oriented

4

Transport (connection-oriented)

3

Network (connectionless)

2"

Logical Link Control

medium access

2'

Link (Medium Access)

media

1

Physical

implicit

implicit

Logical Link

Control

connectionless

connectionless

common

Industrial Automation

2013

Management

Interface

Field Bus Operation 3.2 - 35

Application View Of Communication

Periodic Tasks

R1

R2

R3

Event-driven Tasks

R4

E1

Variables Services

(Broadcast)

node

E3

Message Services

Traffic

Memory

Process Data

E2

Queues

Supervisory

Data

Message Data

(unicast)

bus controller

bus

Industrial Automation

2013

Field Bus Operation 3.2 - 36

Cyclic or Event-driven Operation For Real-time ?

The operation mode of the communication exposes the main approach to

conciliate real-time constrains and efficiency in a control systems.

cyclic operation

event-driven operation

Data are transmitted at fixed intervals,

whether they changed or not.

Data are only transmitted when they

change or upon explicit demand.

Deterministic: delivery time is bound

Non-deterministic: delivery time vary widely

Worst Case is normal case

Typical Case works most of the time

All resources are pre-allocated

(periodic, round-robin)

Best use of resources

(aperiodic, demand-driven, sporadic)

object-oriented bus

message-oriented bus

Fieldbus Foundation, MVB, FIP, ..

Profibus, CAN, LON, ARCnet

Industrial Automation

2013

Field Bus Operation 3.2 - 37

Fieldbus: Time distribution

3.1 Field bus types

3.2 Field bus operation

Data distribution

Cyclic Operation

Event Driven Operation

Real-time communication model

Time distribution

Networking

3.3 Standard field busses

Industrial Automation

2013

Field Bus Operation 3.2 - 38

Time: TAI and UTC

TAI (Temps Atomique International) is the scientific time scale. It is continuously

incrementing and will never be reset or discontinued. It is the base of all other scales.

UTC (Universal time coordinated) is the legal time. It is the base for the clocks of all

countries. It indicates approximately 12:00:00 at solar noon in Greenwich at the Spring

equinox (it was formerly called Greenwich Mean Time). The Bureau International des

Poids et Mesures (BIPM), Paris, is responsible for the definition of UTC.

Rate: UTC and TAI proceed at exactly the same rate; both were identical back in 1961.

Leap Seconds: Since 1961, the earth rotation slightly slowed down, days became longer. When

the difference between UTC and solar noon exceed 0,9 s, which happens after some years, the

BIMP adjusts UTC by letting all clocks insert a leap second, so the last minute of a day lasts 61

seconds (the reverse case is also possible, but very unlikely).

Leap seconds cannot be anticipated, since irregularities of the earth’s rotation are unpredictable.

In 2011, UTC lagged behind TAI by 34 seconds: when TAI was 2011-02-04 12:00:00, UTC was

2011-02-04 11:59:26.

One cannot deduce TAI time from UTC time without a table of all elapsed leap seconds, and

UTC cannot be predicted for a given TAI, since the introduction of a leap second is a decision of

the BIPM. The system of leap seconds is still subject to discussion and could be revised in the

future – it could be abolished in 2015.

Industrial Automation

2013

Field Bus Operation 3.2 - 39

Time-stamping and synchronisation

In many applications, such as disturbance logging and sequence-of-events,

the exact sampling time of a variable must be transmitted together with its value.

For this purpose, the devices are equipped with a clock that records the creation date of

a value (not the transmission time).

To reconstruct events coming from several devices, clocks must be synchronized.

considering transmission delays over the field bus (and in repeaters,....)

A field bus provides means to synchronize clocks despite propagation delays and

failures of individual nodes.

t1

t2

processing

input

input

input

t3

t4

bus

t1 val1

Industrial Automation

2013

Field Bus Operation 3.2 - 40

Syntonization vs Synchronization

distinguish:

1) frequency synchronization (syntonization)

2) relative synchronization

3) absolute synchronization

Industrial Automation

2013

Field Bus Operation 3.2 - 41

Example: Phasor information

Phasor transmission over the European grid: a phase error of 0,01 radian is allowed,

corresponding to +/- 26 µs in a 60 Hz grid or 31 µs in a 50 Hz grid.

Industrial Automation

2013

Field Bus Operation 3.2 - 42

Time distribution

In master-slave busses, the master distribute the time as a bus frame.

The slave can compensate for the path delays. Time is relative to the master

In demanding systems, time is distributed over separate lines as relative time (e.g.

PPS = one pulse per second) or absolute time (IRIG-B), with accuracy of 1 µs.

In data networks, a reference clock (e.g. GPS or atomic clock) distributes the time.

A protocol evaluates the path delays to compensate them.

• NTP (Network Time Protocol): about 1 ms is usually achieved.

• IEEE 1588, all network devices collaborate to estimate the delays, an accuracy

below 1 µs can be achieved without need for separate cables (but hardware

support for time stamping required).

(Telecom networks typically do not distribute time, they only distribute frequency)

Industrial Automation

2013

Field Bus Operation 3.2 - 43

NTP (Network Time Protocol) principle

client

t1

network

server

time request

t2

network

delay

time response

t3

t4

time request

(t 4 t1 ) (t3 t 2 )

2

t’1

t’2

time response

network

delay

t’4

t’3

distance

time

Measures delay end-to-end over the network (one calculation)

Problem: asymmetry in the network delays, long network delays

Industrial Automation

2013

Field Bus Operation 3.2 - 44

IEEE 1588 principle (PTP, Precision Time Protocol)

Grand Master Clock

residence time

calculation

peer delay

calculation

MC

Pdelay-response

TC

Pdelay-request

TC

TC

MC = master clock

TC

TC

TC = transparent clock

OC = ordinary clock

OC

OC

OC

OC

Two calculations: residence time and peer delay

All nodes measure delay to peer

TC correct for residence time (HW support)

Industrial Automation

2013

Field Bus Operation 3.2 - 45

IEEE 1588 – 1 step clocks

time

ordinary

(slave) clock

t1

peer delay

calculation

Pdelay_Req

bridge

bridge

1-step

transparent

clock

1-step

transparent

clock

t2

t1

link delay

t4

t3

Pdelay_Resp

(contains t3 – t2)

grand

master clock

Pdelay_Req

t1

Pdelay_Req

t2

Pdelay_Resp

t3

t4

t2

Pdelay_Resp

t3

t4

Sync

residence

time

residence time

calculation

t5

residence

time

Sync

t5

t6

Sync

(contains all + )

distance

Grandmaster sends the time spontaneously.

Each device computes the path delay to its neighbour and its residence time

and corrects the time message before forwarding it

Industrial Automation

2013

Field Bus Operation 3.2 - 46

References

To probe further

• http://www.ines.zhaw.ch/fileadmin/user_upload/engineering/_Institute_und_Zentr

en/INES/IEEE1588/Dokumente/IEEE_1588_Tutorial_engl_250705.pdf

• http://blog.meinbergglobal.com/2013/11/22/ntp-vs-ptp-network-timingsmackdown/

• http://blog.meinbergglobal.com/2013/09/14/ieee-1588-accurate/

Industrial Automation

2013

Field Bus Operation 3.2 - 47

Fieldbus: Networking

3.1 Field bus types

3.2 Field bus operation

Data distribution

Cyclic Operation

Event Driven Operation

Real-time communication model

Time distribution

Networking

3.3 Standard field busses

Industrial Automation

2013

Field Bus Operation 3.2 - 48

Networking field busses

Networking field busses is not done through bridges or routers,

because normally, transition from one bus to another is associated with:

- data reduction (processing, sum building, alarm building, multiplexing)

- data marshalling (different position in the frames)

- data transformation (different formats on different busses)

Only system management messages could be threaded through from end to end,

but due to lack of standardization, data conversion is not avoidable today.

Industrial Automation

2013

Field Bus Operation 3.2 - 49

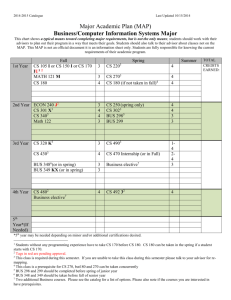

Networking: Printing Example

MPS = Master Printing System

LS = Leitstand

(section supervision)

PM = Print Master

SS =Section Steuerung

(section control)

MPS

Production

Plant-bus (Ethernet)

Operator bus (Ethernet)

Console,

Section Supervision

LS LS LS PM

LS LS LS PM

LS LS LS PM

LS LS LS PM

Printing Towers

Section Busses (AF100)

B

C

Section Control

E

D

SSB

SSC

SSD

SSE

Line bus (AF100)

Reelstand-Gateways

RPB

RPC

RPD

RPE

Reelstand bus (Arcnet)

Reelstands

multiplicity of field busses with different tasks, often associated with units.

main task of controllers: gateway, routing, filtering, processing data.

most of the processing power of the controllers is used to route data

Industrial Automation

2013

Field Bus Operation 3.2 - 50

Assessment

What is the difference between a centralized and a decentralized industrial bus ?

What is the principle of source-addressed broadcast ?

What is the difference between a time-stamp and a freshness counter ?

Why is an associative memory used for source-addressed broadcast ?

What are the advantages / disadvantages of event-driven communication ?

What are the advantages / disadvantages of cyclic communication ?

How is time transmitted ?

How are field busses networked ?

Industrial Automation

2013

Field Bus Operation 3.2 - 51