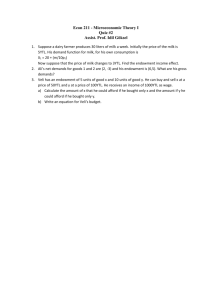

ANS 110 Oct 18

advertisement

Prevention • Make sure milking equipment is operating properly • Try to have cows remain standing for a time period after milking • Use separate cloths or towels for each cow to clean the teats • Immediately after milking, dip each teat with a teat dip solution Milking Cows Mastitis The antibiotic residue in milk is zero Human allergies to antibiotics Effects on processing properties Sequence of Events Reproductive Cycle Calving 82 d Calving 283 d ---------------------------------------------------------------Pregnant Not Pregnant Lactation Cycle 305 day lactation Calving Calving 60 d “Dry” ----------------------------------------------------------------120 90 Lactation Curve Milk lb/day 60 30 60 90 Days Postpartum 305 Dry Body Condition Scoring - Scale 1 -- 5 Body Condition score = 1 Body Condition Scoring - Scale 1 -- 5 Body Condition score = 2 Body Condition Scoring - Scale 1 -- 5 Body Condition score = 3 Body Condition Scoring - Scale 1 -- 5 Body Condition score = 4 Body Condition Scoring - Scale 1 -- 5 Body Condition score = 5 Milk • Definition – “Milk is the lacteal secretion, practically free from colostrum, obtained by the complete milking of one or more healthy cows, containing not less than 3.25% of milkfat and not less than 8.25% of milk-solids-not-fat” Milk Composition • • • • • 87.3% water 3.7% milkfat 3.4% protein 4.9% lactose 0.7% ash Milk Factoids • ~ 12 % of the American household’s total food expenditure is for dairy products • Milk and milk products provide 10 % of total calories in the U.S. food supply Milk Consumption and Usage 1992 1996 (Million Pounds) Fluid products 58.5 Manufactured Products Butter American Cheese Other Cheeses Ice Cream 92.2 30.48 29.26 20.19 14.19 59.3 91.5 26.19 32.55 21.39 15.25 Milk Fat • Most variable component of milk • 97-98% triglycerides (short- and long-chain fatty acids with different degrees of saturation) • Fat droplets, encased in part by proteins, form the cream of milk • Synthesis of fatty acids – Non-ruminants- glucose precursor – Ruminants – volatile fatty acids Milk Protein • Major groups – caseins (82%) – 4 types; precipitate from skim milk at pH 4.6 – whey proteins (18%) - alpha-lactalbumin and betalactoglobulin – Other proteins (minor amount) • • • • Enzymes Transport of nutrients Disease resistance (antibodies, etc.) Growth factors • Growth and development of neonate – Appropriate amino acid profile – Growth factors Milk Lactose • Unique to the mammary gland • Major carbohydrate in milk • Disaccharide composed of glucose and galactose • Attracts water movement into mammary secretory cells Minerals • Milk minerals provide necessary components for skeletal development of the young • Calcium and phosphorus are main milk minerals and are necessary for bone formation From farm to market • Cooperatives – Michigan Milk Producers Association • 3 billion lbs/year, 11th in U.S • Owned by producers; 100% of net margin returned to producers at end of year • Market the farmers’ milk to bottlers, processors & other manufacturing Where is Michigan milk used? • • • • • • Butterball Farms Entenmann’s Elias Brothers Great Lakes Caramel Nestle Hunt-Wesson • • • • • • Butter patties Pastries Ice cream Caramel Apples Frozen dinners Snack pudding Milk pricing example • Component pricing – – – – Butterfat: $1.67/lb x 3.5 lb = $5.85 Protein: $1.68/lb x 3.16 lb = $5.31 Fluid carrier: $.28/cwt x 93.34 = $.26 Price differential = $1.32 • Blend price • Over-order Premium $12.74 $13.15 Grades of milk I • Refer to quality of milk • Grade A – 1) Temperature: cooled to 45 °F (7 °C) or less within 2 h after milking, provided that the blend temperature after the first and subsequent milkings does not exceed 50 °F (10 °C) Grades of milk II • 2) Bacteria: – a. Less than 100,000 CFU/ml of milk – b. Less than 300,000 CFU/ml as commingled milk prior to pasteurization • 3) Antibiotics • 4) Somatic cell counts (SCC) not to exceed 750,000 per ml Grades of milk III • Grade B – bacteria 1,000,000 CFU/ml – SCC 1,500,000/ml Precautions for the producer • Herd health – Disease – Antibiotics • Added water • Sanitation program Processing Terminology Homogenization • Reduction of fat globules from 3 - 20 µm diameter to <2 µm • Prevents cream from rising to the top Processing Terminology: Pasteurization By law, all fluid milk sold for human consumption must be pasteurized • Purposes – primary: destroy pathogens – secondary: destroy spoilage organisms • Pasteurizing occurs at – 145 ° F for 30 min – 161 ° F for 15 s – 191 ° F for 1 s – 212 °F for .01 s Fluid Milk Products • Whole Milk: >3.25% milkfat, >8.25% milk SNF (solids not fat) • Lowfat Milk – ½ -- 1 ¼% milkfat, >8.25% milk SNF • Skim Milk - <1/2% milkfat, >8.25% milk SNF • Half-and-Half • >10.5% but <18% milkfat Ice cream and frozen desserts • Composition – ice cream – >10% milkfat; >20% total milk solids – must contain >1.6 lb total solids/gallon – Reduced fat ice cream – 25% reduction in fat content – Lowfat ice cream – 3 g fat per serving (1/2 cup) – Nonfat ice cream – 1/2 g milkfat per serving (1/2 cup) Other products • • • • • Cottage cheese Cheeses Whey powder Butter Powder • Long shelf life, reconstituted to use in bakery products and other foods • Major export product Fermented dairy foods • Yogurt – Produced by adding a bacteria (lactobacillus) to milk – Bacterial action produces lactic acid – The lactic acid will then make the milk curdle yogurt • Buttermilk • Sour cream Milk Required to make: One pound of: Butter Whole milk cheese Requires: 21.2 lbs of whole milk 10.1 lbs of whole milk Ice cream ( 1 gallon ) 12.0 - 15.0 lbs whole milk Cottage cheese 6.25 lbs of skim milk