DMI - Delta Mold Inc.

advertisement

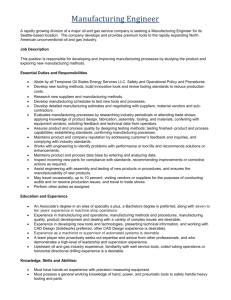

DMI (Delta Mold Inc.) Your Global Resource for Injection Mold Tooling Charlotte, North Carolina (USA) ISO 9001: 2000 Certified Charlotte NC Facilities HEADQUARTERS BUILDING 54,000 Sq. / ft Charlotte NC Facilities (Continued) ADJACENT SUPPORT FACILITY 14,000 Sq./ft -Key Facts Established 1978 Privately Owned Annual Sales $20 + Million ISO 9001: 2000 Certified 53,000 square feet of Climate Controlled Manufacturing-14,500 Square Feet of Administrative and Engineering Total Employees 85 (Strategic Alliances) * Delta Technologies Group * Offshore Partnerships * Offshore Partnerships Auburn Hills Michigan Taipei Taiwan / Suzhou China Qingdao China Equipment Overview Main Tooling Facility Repair Facility 3- Overhead Cranes 1-25 ton, 2-20 ton 2- Mecof High Speed Mills. 1- large CS 500, and 1- Medium Performa 4- Boring Mills 1- Johnford High Speed Mill 2- Gundrill 2- Small Droop & Rien’s Retro-Fitted for High-Speed 11- Bridgeports 1- Parpas High Speed 5 Axis Mill 1- Lathe 1- 10-ton crane 1- Johnford High Speed Mill 1- Drill Press 1- Lathe 2- Bridgeports 1- OKK milling machine 2- Boring Mills 4- Depo Mills (Details and small tools) 4- Spotting Presses 1- Makino V-55 N/C Machine for Cutting Electrodes 2- Large Makino EDNC 156 tank EDM’S 4- Medium Size Elox Tanks 4- Surface Grinders 1- 2500-Ton Cincinnati Co-Injection Press 1- Toshiba 950-Ton Sampling Press Machine Limits Mecof # 1 Mecof # 2 Toshiba # 1 Toshiba # 2 Toshiba # 3 Toshiba # 4 Toshiba # 5 Wotan BM Droop # 1 Droop # 2 Depo # 1 Depo # 2 Depo # 3 Depo # 4 Gundrill 157 90 79.5 98 78.7 78.7 118 70 74.2 73.8 50 50 40 40 104 X 67 39 59 59 59 59 90.5 40 37.2 33.2 23.7 23.7 24 24 58 Y 39.3 47 55 60 55 55 63 58 33.3 33.3 30 30 25 25 96 Z Weight 70,500 70,500 13,800 17,600 13,800 13,800 33,000 6,000 15,400 15,400 3,000 3,000 2,000 2,000 60,000 Table 208 x 43 Fixed 86 x 45 63 x 55 Rotary 98 x 59 Fixed 63 x 55 Rotary 63 x 55 Rotary 86 x 72 Rotary 72 x 44 Rotary 94 x 39 Fixed 94 x 39 Fixed 57 x 24 Fixed 57 x 24 Fixed 50 x 23 Fixed 50 x 23 Fixed 96 x 60 Fixed Our Quality Beliefs & Targets Build the Best Mold, for the Best Price, on Time, Every time, Better Serve Our Customer Needs. To Provide Products and Services That Not Only Meet, But Exceed the “Expectations of Our Customers”. Continue Our Reputation As a Company That Cares For Our Customer’s Needs, While Developing and Maintaining a Strong Working Partnership. Quality Certifications ISO 9001: 2000 (Core Business) Production & Prototype Tooling PRODUCTS: LATEST AVAILABLE TECHNOLOGIES INCLUDING: 3D Model Tool Design Solids (IDEAS) PowerPoint Feasibility Studies Solidworks / Moldworks Direct Real Time CNC Machining High Speed Machining Centers Production Injection Molds External & Gas Assist Tools Stack Molds Compression, and RIM Molds Aluminum Prototype Tooling Continually Updated New Technologies / Capital Investments Research, Development and Implementation of New Equipment and Technologies High Speed Machining (9 Machines) Tool Tryout/Customer Support 950-Ton Toshiba Injection Press New Cincinnati 2500-Ton CoInjection Press Tool Design and Tooling Process Enhancements CAD Data Management New Technologies / Capital Investments (Continued) 3D Solids Technology 100 % Paperless in Tool Design and Manufacturing Real-Time Programming Of all CNC Equipment Latest Technology in High-Speed Milling Tooling Verification / Customer Support 950-Ton Toshiba Ejection Press with Gas Assist, Sequential Gating, and Counter Pressure Capabilities Tooling Verification / Customer Support (Continued) New 2500-Ton Twin Barrel Cincinnati Co-Injection Press. (Single Barrel Machine Shown Below) Tooling Verification / Customer Support (Continued) CMM Machine for Small Jobs & Limited Part Inspections Portable Romer CMM Arm For Infinite Size Tooling Tooling Facility Pictures 1st Bay, Machine Row 2-High-Speed Mecof’s , 1-High-Speed Parpas, 4- High-Speed Depos, 4-Boring Mills, 2-Droop & Rein, 1-Gundrill Tooling Facility Pictures 2nd Half of First Bay Tooling Facility Pictures Middle Bay, Assembly & Spotting Tooling Facility Pictures 3rd Bay, EDM Department, Benching & Tryouts Wide Ranging Tooling Capabilities From Small Too Large Wide Ranging Tooling Capabilities Tooling / Product “Samples” Tooling / Product “Samples” CAD DATA MANAGEMENT • Full Time Data Administrator • T-1 Data Transfer • CAD/CAM Workstations (35) • Intranet Based Data Vault • Capable of Direct Translation of These Formats: CATIA, UniGraphics, I-DEAS, Pro-E, IGES, STEP,VDA, SOLIDWORKS. Delta / Customer Partnership Advantages • Early Tool & Part Feasibility Reviews For Improved Product and Tool Harmony • Dedicated Program Management • Budget Control • Meeting Participation • Data Coordination • Timing & Progress Reporting Major Customers Delta Mold Contacts Title/Department Contact Name E-mail Address Ext. Executive Officer President COO Executive Vice President VP New Product Designs Business Unit Director Program Manager Program Manager Office Manager Purchasing Quality Manager Advanced Technology Specialist Human Resources Customer Service Administrator System/Data Administrator Eric . H Mozer Donald W. Wisch Jim Quinn Thomas F. Werner Danny L. Johnson Doug Davis Bill Hencak Greg Rosmon Judith A. Harkey Debbie Rose Ginger Hughes Bill Cole Rachel Palermo Kim Wisch Nathan Wisch emozer@deltamold.com dwisch@deltamold.com jquinn@deltamold.com twerner@deltamold.com djohnson@deltamold.com ddavis@deltamold.com bhencak@deltamold.com grosmon@deltamold.com jharkey@deltamold.com drose@deltamold.com ghuges@deltamold.com bcole@deltamold.com rpalermo@deltamold.com kwisch@deltamold.com nwisch@deltamold.com 206 228 233 227 221 208 209 211 204 231 232 331 202 210 235 REFERENCES AVAILABLE UPON REQUEST