Yarn Appearence - Prof. Dariush Semnani

advertisement

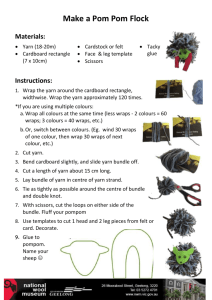

Grading of Yarn Appearance Using Image Analysis and Artificial Intelligence Technique Dariush Semnani Oct 2004 1 HIGH LIGHT POITS ASTM Standard Method (Section: D2255) Previous Methods for using computer vision in yarn apparent grading The aim of present research Methodology Results and discussion Conclusion Oct 2004 2 ASTM Standard Method (Section: D2255) Yarn grading based on appearance Use for short staple yarns Four grade, six category of yarn count Definition of yarn grades Methodology is based on human vision Comparing with standard boards of yarn Oct 2004 Grading is only for apparent features Not for every yarn Types It is not capable for grading of yarn in extended region Objective so non calculative Mistakes of human vision, Different judges Difficult conditions for experiment 3 A Sample for Standard Boards Cat.: 16-25 TEX Grade A Oct 2004 Grade B Grade C Grade D 4 Previous Methods for using computer vision in yarn apparent grading Scanning of a yarn thread in different equal sections with CCD camera. Measuring of yarn diameter by image processing. Detecting of unevenness of yarn. Assign a grade to yarn based on diameter unevenness. Modeling of yarn board by sorting of scanned threads as EIB board. Oct 2004 Lightening problems, not conformed with standard method. Not capable for detecting of yarn body region. Faults could not been classified. Assigned grade is not conformed with standard. Real board has objective appearance. 5 The aim of present research Present a new method for yarn grading based on appearance which is conformed with standard and useable for yarn boards Useable for different yarn counts and yarn types. Capable to classify faults based on configuration Use image processing technique for yarn board Development of grading region Calculation of faults. Definition of numerical index of grade by fuzzy logic Oct 2004 6 Methodology Definition of apparent yarn feature based on various kinds of fault Elimination of yarn body from picture of yarn table Elimination of background from yarn core eliminated image Counting and classification of faults Grading of yarn appearance based on fault factors Oct 2004 7 Definition of apparent yarn feature based on various kinds of fault STANDARD DEFINITION: nep with thickness of less than three times of yarn diameter. nep with thickness of more than three times of yarn diameter. Foreign trashes. Fettling fibers with thickness of less than three times of yarn diameter such as small bunch, slug, or slub. Fettling fibers with thickness of more than three times of yarn diameter such as big bunch, slug, or slub. Unevenness coating of yarn surface with shapes of fuzziness. Free fibers on yarn surface. These fibers are named fuzz. The fuzz should not be confused with the cover. Oct 2004 SUMMERIZED DEFINITION: Class I: Big and entangled faults which are tightened fibers with uniform configuration. Class II: Big faults with less area in comparison with first category (Class I). Class III: Non uniform and extended faults with spread configuration. Class IV: Small spread faults such as non uniform coating fibers and short tangled hairs. 8 Definition of fault classes All of the big tightened faults such as fettling fibers, tangled fibers, big neps, big melted spots and confused helical fibers are classified in class I. These faults have big tangled area. Other similar faults with smaller are in comparison with class I are classified in class II. Long spread fibers as small fuzz are classified in class III. These faults are spread in area. Small spread coating fibers and different small faults are classified in class IV. Oct 2004 9 Class IV A Sample for faults Class II Class III Class I Class III Class I Oct 2004 10 Elimination of yarn body from picture of yarn table Scanning of board (300 DPI, Gray Scale 256, 10 by 9 inch) More Resolution=More Processing Time & Less Res.=Less Accuracy Converting image to binary mode (Level 110) Elimination of yarns Cores Oct 2004 11 Relation between original image and faults image F=G+N M j f i, j / M i1 If j T f i , j gi, j 0 If i T Oct 2004 f i, j n i, j 0 If If T j T j 12 Why it is required to divide image to tapes d d0 l=100 α x tg 5 degree l0 x=8 EX: 65 Tex N N0 x d l x 0 d 0 l0 l l0 N N0 l 12.4 N x0 Oct 2004 13 Finding Threshold for detecting of thread core b Curve : Sorted vector of columns means for whole tapes a: Turning point Th: Threshold for thread core X : sorted vector of means Intensity: 0-1 m. (h 1)X / 2 1 a Th c h i i 1 1 h ( x 0) X 1 h y x h X yh Oct 2004 X In nominal method, point (a) is located where the difference between vector of line cb and sorted mean vector (curve) is in minimum. The height of point (a) is desired threshold value (Th). 14 Oct 2004 15 Elimination of background from yarn core eliminated image A small threshold for detecting of black columns in every tape = 0.1 Procedure verifies every column with threshold for whole tapes. After elimination of black columns length of tape is various among different tapes. So the image of fault is a wide image with height of tape length and width of remained columns (not black). Oct 2004 16 Counting and classification of faults Convert Fault Image to blocks vector Finding optimum block size Estimation of optimum values for thresholds Classification of blocks by estimated thresholds Oct 2004 17 Image Blocking Tape length Width= remained columns Size: B by B Width= remained columns x tape length / B2 Oct 2004 18 Finding Optimum Block Size Calculation of Variance of blocks means for different block size Optimum block size has Maximum variance of block means Oct 2004 19 Estimation of Optimum Values for Threshold TFm= Threshold of blocks means TFv= Threshold of blocks variances TFm : for bigness of fault in block TFv =for configuration of fault in block Thresholds are located in turning point of sorted vector of means and variances Turning point is calculated by numerical second order differential of vectors Oct 2004 Sorted vector of means or deviations of blocks Tf Index of vector 20 Classification of blocks by estimated thresholds -Class I: Condition: bi 1.2T fm N1 . Big neps, slug or slubs, and other big tangled faults are classified in this class. -Class II: Condition: T fm bi 1.2T fm & vbi T fv N2 . Entangled faults which are smaller than faults of class I is classified in this class. -Class III: Condition: T fm bi 1.2T fm & vbi T fv N3 . The faults which are spread in block is classified in this class. Class IV: Any other blocks which are not classified in above classes . The spread small faults are located in this class Oct 2004 N4 21 The error of bad classification of faults between tow blocks Error of the worst situation for the thinnest yarn = 0.036% Error of the worst situation for the thickest yarn = 2.5% Oct 2004 16 pixels Region between blocks 22 N1 K K PFF 100 MN N2 K K PHF 100 MN N3 K K PLF 100 MN Oct 2004 N4 K K PNF 100 MN 23 Table 1: Suitable Tape and block size for core elimination of threads and classification of faults in images of standard boards Block size Length (Pixels) tapes (Pixels) Yarn Count of board (Tex) Region of yarn Count (Tex) Category 16x16 35 8 4-8 I 20x20 40 12 8-12 II 25x25 50 16 12-16 III 30x30 60 20 16-25 IV 45x45 90 50 25-50 V 50x50 100 65 50-590 VI Oct 2004 24 Category Grade Tfm Tfv A 0.32 0.16 B 0.31 0.15 C 0.28 0.16 D 0.29 0.16 A 0.35 0.18 B 0.40 0.19 C 0.30 0.16 D 0.32 0.17 A 0.25 0.13 B 0.26 0.13 C 0.30 0.17 D 0.29 0.18 A 0.24 0.11 B 0.20 0.14 C 0.20 0.14 D 0.20 0.15 A 0.37 0.20 B 0.21 0.15 C 0.16 0.12 D 0.16 0.13 A 0.18 0.13 B 0.25 0.15 C 0.20 0.15 D 0.19 0.15 I II Table 2: Threshold values for classification of fault blocks in images of standard boards III IV V VI Oct 2004 25 Grading of yarn appearance based on fault factors ID=P.W PFF PHF P PLF PNF Oct 2004 W [ w1, w2, w3, w4] 26 Estimation of W (Classifier Ceriteria) from ANN 6 ANN for 6 classifier regarding to 6 Categories Fuzzy Layer PFF w1 ANN : Perceptron with 2 layers PHF Fuzzy layer only in use w2 ID w3 Training : 10000 epok with training rate 0.1 PLF w4 Grade PNF Oct 2004 27 Results and discussion Cat. I, II, III: PFF weight of big faults (PFF) which is named W1, is more important in weights Cat. IV and V: both of PFF and PHF are effective on yarn appearance, the effect of spread faults is less than tangled faults, but the difference of these faults with tangled faults is less than previous categories Cat. VI: small and spread faults are more effect on yarn appearance in comparison with last categories, though weight of tangled faults is more than small and spread faults Oct 2004 28 Category Grade PFF PHF PLF PNF A 0.01 0 0.91 25.94 B 0.19 0 3.16 39.49 C 0.03 0 1.37 48.12 D 0.12 0 3.46 58.28 A 0 0 1.01 50.44 B 0 0 1.46 56.39 C 0.11 0 1.26 43.1 D 0.12 0 2.03 39.25 A 0.01 0 1.26 31.03 B 0.11 0 1.61 34.75 C 0.77 0 10.49 29.8 D 1.86 0 8.24 29.4 A 0.02 0 1.07 23.53 B 2.75 0.11 6.25 14.26 C 5.07 2.18 5.36 10.57 D 7.54 7.32 0 6.41 A 5.72 0 11.81 36.78 B 6.03 13.45 5.16 22.51 C 18.26 0 13.65 7.26 D 15.19 14.06 1.64 8.38 A 2.96 4.74 10.54 23.17 B 6.06 0 14.4 24.88 C 14.4 12.31 3.66 14.71 D 17.3 17.43 0 10.35 I II Tabel 3: Calculated factors for images of standard boards III IV V VI Oct 2004 29 Table 4: Region of grades indexes and indicator values Indicator value Region of apparent grade A 25 Less & 20-40 B 50 40-60 C 70 60-80 D 90 80-100 & above Grade of appearance Oct 2004 30 Category Grade W1 W2 W3 W4 A 33.221 B I Table 5: Faults weights which are calculated from standard pictures by neural nets 59.363 29.999 1.999 1.999 1.199 C 61.334 D 80.393 A 37.397 B II 50.077 249.99 24.99 24.99 0.241 C 69.375 D 90.190 A 34.934 B III 41.957 24.891 1.891 1.891 1.041 C 70.024 D 92.485 A 26.195 B IV 50.008 6.377 5.077 2.877 0.977 C 69.147 D 91.509 A 24.112 B V 56.002 3.697 2.397 0.167 0.027 C 69.983 D 90.359 A 29.389 B VI Oct 2004 Grade Index by Modified Weight Factor from ANN 41.128 4.136 0.939 0.789 0.189 C 76.785 D 89.876 31 Table 6: Minimum error of training for neural nets SSE Minimum error I 322.649 18.666 II 154.117 12.711 III 169.539 14.654 IV 4.432 1.923 V 36.942 3.995 VI 144.028 11.282 Category Oct 2004 32 Table 7: Recommended grades for grading of yarns based on appearance Grade of yarn appearance based on ASTM grading A B C D Oct 2004 Developed grades Region of Index of degree A+ 0-20 A 20-30 A- 30-40 B+ 40-50 B 50-60 C+ 60-70 C 70-80 D+ 80-90 D 90-100 D- Above 100 33 Conclusion Detection and classification of faults from yarn board Measurement of faults by image analysis and box counting method Grading of yarn appearance from measured faults by a classifier criteria. Estimation of classifier criteria by using ANN. The error of grading is acceptable. The presented method is independent to faults nature and it works based on their apparent parameters It is possible to develop this method for grading of other types of yarn such as worsted, woolen, filament, high bulk and textured yarns Oct 2004 34