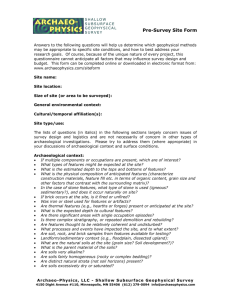

Investigation Stage

advertisement

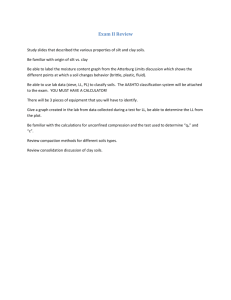

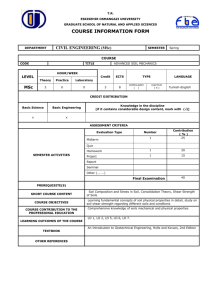

P. JOHN VICTOR RESEARCH OFFICER A.P. Engineering Research Laboratories, Himayatsagar, Hyderabad –500 030. Site Selection for Dam i) Geographical Location – Configuration, Contours, Gorge Portion, Valley Shape ii) Sound Foundation iii) Borrow Area Selection – Nearby. iv) Spillway Section. v) Submergence Consideration vi) Facility of Transportation vii) Controlled Pollution – Deforestation Why “Foundation Soil” Studies? If Foundation Soils are of : i) Rock Foundation – Less Problematic, Grouting to take care of sliding at joints, Seepage control, Field Permeability Tests, Geologist’s Report. ii) Gravel and Dense Sands – Stability is not the problem but Seepage. Contd... If Foundation Soils are of : iii) Fine Sands – Problem of liquefaction due to sudden stress, earth quakes, .... Application of sudden shear stress prevents drainage Large pore pressures. Better to Compact or Remove it. Seepage control measures are to be taken. iv) Clay Foundations – High Plasticity, Low Shear Strength, Slow rate of Consolidation,... Leads to Stability Problem. Remedy is flattening of slopes, ground improvement methods. Contd... If Foundation Soils are of : v) Mixed Layers – Strata of impervious nature at top and pervious soils at depths – high seepage pressures at the toe of the Dam. Remedy is proper drainage and / or loading berm to avoid the danger of blow or piping. vi) Miscellaneous – Actual conditions at the site can be more and more complex !!! EARTHEN EMBANKMENTS MAIN ZONES (FOR SOIL TESTING): HEARTING CASING COT FILTERS TESTS ON SOILS FOR IRRIGATION PROJECTS • Pre Construction • During Construction • Post Construction WHY PRE CONSTRUCTION SOIL EXPLORATION? • Determination of Site Characterization • For bringing out deficiencies / evaluating strength • For arriving at Suitability / Improvement • To provide design inputs in an unambiguous manner - more realistic • To evolve a proper and adequate design avoiding assumptions PRE CONSTRUCTION TESTS a) Along Proposed Axis (Foundations) b) Borrow Area Soils c) Spillway Location d) CM & CD Works e) CNS Soils for Canals f) Filters a) ALONG PROPOSED AXIS (FOUNDATIONS) • CLASSIFICATION TESTS: – Mechanical Analysis • Sieve Analysis • Hydrometer Analysis – Atterberg Limits • Liquid Limit • Plastic Limit • Shrinkage Limit a) ALONG PROPOSED AXIS (FOUNDATIONS) Contd.. • • • • LABORATORY / INSITU PERMEABILITY TEST DIFFERENTIAL FREE SWELL TEST FIELD DENSITIES & MOISTURE CONTENT SHEAR PARAMETERS – TRIAXIAL SHEAR TEST – DIRECT SHEAR TEST – UNCONFINED COMPRESSION TEST • CHEMICAL ANALYSIS • BEARING CAPACITY COMPUTATIONS b) TESTS ON BORROW AREA SOILS • CLASSIFICATION • LABORATORY PERMEABILITY TEST • DIFFERENTIAL FREE SWELL TEST ( IF DFS > 50% , BETTER TO CONDUCT SWELL PRESSURE TEST ) • PROCTOR’S COMPACTION TEST • SHEAR PARAMETERS – TRIAXIAL SHEAR TEST – DIRECT SHEAR TEST – UNCONFINED COMPRESSION TEST • CHEMICAL ANALYSIS • EFFECTIVE STRESS PARAMETERS c) TESTS FOR SPILLWAY CONSTRUCTION • INSITU PERMEABILITY TESTS – SINGLE PACKER METHOD – DOUBLE PACKER METHOD (TO DECIDE ABOUT THE GROUTING) • FIELD ROCK SHEAR TEST (TO ASCERTAIN THE BOND BETWEEN THE NATURAL ROCK AND CONCRETE) • GEOLOGIST’S REPORT d) TESTS FOR CM & CD WORKS • COLLECTION OF UNDISTURBED SOILS (TO COMPUTE THE SAFE BEARING CAPACITY) • DIFFERENTIAL FREE SWELL • PLATE LOAD TEST e) TESTS ON CNS SOILS • MECHANICAL ANALYSIS – SIEVE ANALYSIS – HYDROMETER ANALYSIS • ATTERBERG LIMITS – LIQUID LIMIT – PLASTIC LIMIT • SWELL PRESSURE TEST REQUIREMENTS TO USE AS CNS SOIL • • • • • • • GRAVEL ( > 2 MM ) 0 – 10% SAND ( 2 - 0.06 MM ) 30 – 40% SILT ( 0.06 – 0.002 MM ) 30 – 40% CLAY ( < 0.002 MM ) 15 – 20% LIQUID LIMIT 30 – 50% PLASTIC LIMIT 20 – 25% SWELL PRESSURE < 0.10 Kg/Sq.Cm. IS 9451-1994 f) TESTS FOR FILTERS • MECHANICAL ANALYSIS – SIEVE ANALYSIS – HYDROMETER ANALYSIS – GRADATION CURVE FILTERS (IS 9429 – 1980) Need of Filters: Transition filters are required between impervious zones of fine grained soils, and pervious zones or drains of coarse material to prevent migration of soil grains from the former to the latter. As the direction of seepage is towards the upstream face at the time of drawdown, such filters are needed both on the Upstream and downstream side of the core. FILTERS Requirement of a Filter: a) Its voids should not permit the migration of the particles from the protected zone. b) It should be sufficiently more pervious than the protected zone to induce a sharp reduction in hydraulic gradient. Contd... Requirement of a Filter: D15 of filter D85 of protected soil D15 of filter D15 of protected soil D50 of filter D50 of protected soil <5 > 4 & < 20 < 20 FILTERS Thickness of Filter: a) Horizontal Filter – 15 to 30 Cm. b) Vertical Filter – 1.00 to 1.50 m. INSITU TESTING PROCEDURES & THEIR IMPORTANCE TYPES OF INSITU PERMEABILITY TESTS IN ROCKY STRATA : • SINGLE PACKER METHOD • DOUBLE PACKER METHOD IN SOILS : • JAPANESE METHOD • PUMPING IN TEST • PUMPING OUT TEST IMPORTANCE OF PERMEABILITY DATA • CORE LOGGING OF A BORE HOLE PROVIDES INFORMATION ON THE PHYSICAL CONDITION OF THE ROCK MASS • WATER PERCOLATION TESTS – PERMEABILITY RESULTS OF A STRATA SUPPLEMENTS INFORMATION ON THE DRILL HOLE DATA • WHAT CAN BE THE LOSS DUE TO FEATURES SUCH AS THESE IF STORAGE STRUCTURES CONTEMPLATED? PERMEABILITY • THE STATE OF WATER MOVEMENT BELOW THE SURFACE THROUGH A MEDIUM IS CALLED PERCOLATION AND THE MEASURE OF MOVEMENT CALLED PERMEABILITY DARCY’S LAW • THE FLOW RATE IS PROPORTIONAL TO THE CROSS SECTIONAL AREA OF A MEDIUM THROUGH WHICH THE WATER FLOWS • FOR UNIT CONDITIONS THE EQUATION CAN BE WRITTEN AS Q= KA h/l where K= Co-efficient of permeability Q= quantity of water discharge per unit area of time A= cross sectional area through which it flows h= hydraulic head variation l= the distance in which the head is lost • The Eqn can be re-written as K= Q/A . L/h • Temp and viscosity although affect they are not considered because the effect on flow of water is insignificant WHAT IS LUGEON VALUE? • THE UNITS ARE NORMALLY EXPRESSED IN feet/year; cm/sec; m/sec; feet/day etc. • Another unit commonly used is Lugeon named after a French Engineer M.Lugeon who conceived carrying out water pressure tests • One lugeon is defined as the quantity of water lost in litres/min per metre cross sectional area of bore hole at a pressure of 10 bars • Because of adoptability water tests in river valley projects use this unit which is equivalent to 10 feet/year or 10-5 cm/sec or 10-7 metre/sec PACKER TESTS OR PUMP IN METHOD • SINGLE PACKER METHOD AS THE BORE HOLE PROGRESSES OR • BY DOUBLE PACKER METHOD AFTER COMPLETION OF BOREHOLES • EQUIPMENT REQUIRED ARE DRILLING EQUIPMENT, PRESSURE GAUGE, PUMP, WATER FEEDER LINES, DRILL ROD, PERFORATED ROD AND OTHER FITTINGS WATER METER ETC METHODOLOGY • A MEASURED QUANTITY OF WATER IS PUMPED INTO THE BOREHOLE UNDER KNOWN PRESSURE FOR A UNIT LENGTH OF SECTION • WATER LOST OBSERVED FOR 3 CONTINUOUS READINGS FOR SPECIFIC TIME DURATION. • LUGEONS CALCULATED PRECAUTIONS • SATURATION OF THE TEST SECTIONS FOR A SPECIFIED PERIOD • CALIBRATION OF PRESSURE GAUGES, WATER METRES ETC • USE OF CLEAN WATER TO PREVENT CLOGGING OF THE FEATURES- USE OF SETTLING TANKS • OTHERWISE PERMEABILITY CALCULATIONS CAN BE GROSSLY MISLEADING PROCEDURES • TESTS TO BE PERFORMED UNDER UNCASED SECTIONS AND UNGROUTED SECTIONS AND WHERE DRILLING MUD USED TO BE AVOIDED • PRELIMINARY DRILLING DATA SUCH AS CORE LOSS, COLLAPSED SECTIONS, CHANGE IN LITHOLOGY THEREORE CHANGE IN PERMEABILITY CHRACTERISTICS, POSSIBILITY OF PACKER GETTING STRUCK OR WIDER SECTIONS WHERE PACKER WILL NOT BE SEATED PROPERLY TO BE GATHERED • SINGLE PACKER TESTCAN BE PERFORMED IN HOLES CASING NOT REQUIRED EVEN FOR SOFT SANDSTONE ETC OR WHERE HIGHLY FRACTURED/SHEARED SECTION OF BORE HOLE • IN DOUBLE PACKERS THOUGH EFFICIENT LEAK THROUGH THE LOWER PACKER CAN GO UNNOTICED LEADING TO ERRONEOUS RESULTS • TEST SECTIONS IN ANY CASE SHOULD NOT BE LESS THAN FIVE TIMES THE DIAMETER OF THE BOREHOLES • CYCLIC TESTS ARE PERFORMED TO DETERMINE WASHABILITY AND GROUTABILITY OF JOINTS • PRESSURES TO BE APPLIED IS EITHER GOVERNED BY THE COVER OF ROCK • OR THE FOUNDATION THAT CAN WITHSTAND WITHOUT HEAVING SUBJECT TO MAXIMUM HEAD OF THE RESERVOIR TO BE IMPOUNDED LUGEON CALCULATIONS: Lugeon Value = Intake water in Lt/min/mt X 1MPa Test Pressure (MPa) 1 Kg/cm2 = 10 m head Q = 1.25 Lt/5 min or = 0.0833 Lt/min/mt for 3 m test section H1 = 8.68 m or 0.868 Kg/cm2 H2 = 10 m or 1.00 Kg/cm2 Test Pressure = 1.868 Kg/cm2 = 0.1868 MPa Lugeon Value = 0.833/0.1868 = 0.45 Lugeons H1 = Distance between centre of test section & swivel H2 = Applied Pressure SIZES OF DRILL HOLES Size of Casing Dia. of hole in mm. EX 38.1 AX 48.4 BX 60.3 NX 76.2 JAPANESE METHOD: 2 ft X 4 ft pit ¼ : 1 slope Leave first two readings for one hour each. Then take another minimum of 3 – 4 readings hourly. 4 ft X 4 ft …. Repeat same procedure. BUT…. DEPTH = 1 ft 9 inches and @ 3 inches, tie thread to measure water. Find difference in discharge Difference X 21.2 = k X 10-6 cm/sec GROUTABILITY VS PERMEABILITY • MEDIA INDICATING LESS THAN ONE LUGEON NORMALLY COULD NOT BE GROUTED • BETWEEN ONE TO FIVE LUGEONS USE OF APPROPRITAE PRESSURES AND DETERMINATION OF POST GROUT PERMEABILITY TESTS REQUIRED FOR CROSS CHECKING PLATE LOAD TEST INSITU ROCK SHEAR TEST LABORATORY TESTING PROCEDURES SOIL CHARACTERISATION IDENTIFICATION MECHANICAL ANALYSIS SIEVE ANALYSIS HYDROMETER ANALYSIS ATTERBERG’S LIMITS LIQUID LIMIT PLASTIC LIMIT SHRINKAGE LIMIT CLASSIFICATION NOTATIONS: G – S – M – C – W – P – H – I – L – O – Pt GC – GW – CH – ML ....... SC–SM; GC–SC SIEVE ANALYSIS Why? – To know the grain size distribution of coarse grained soils (gravel & sand) For gravel For Sands 40 mm 2.000 mm 25 mm 0.600 mm 12.5 mm 4.75 mm 0.425 mm 0.250 mm 0.150 mm 0.075 mm ADD DISPERSIVE AGENT SIEVE SETS SIEVE SHAKER HYDROMETER ANALYSIS Why? – To know the grain size distribution of fine grained soils (silt & clay) Grain Size Distribution Clay Silt Particle 0.002 size in mm Sand 0.075 Gravel 4.75 Cobbles 75 GRAVEL 4.75 FINE SAND 0.075 FINE 0.425 2.00 MEDIUM 4.75 COARSE 20 75 COARSE Boulders 300 ATTERBERG’S LIMITS Vol. Cu.Cm. Solid SemiSolid Plastic SL PL Moisture content (%) Liquid LL CASAGRANDE’S LIQUID LIMIT DEVICE Specific Gravity It is the ratio of the mass of a given volume of solids to the mass of an equal volume of water at 4 o C. DIFFERENTIAL FREE SWELL TEST Free Swell Index test IS: 2720 part 40 Graduated glass cylinders100ml sample passing 425 micron sieve 10mg in each cylinder kerosene in one and distilled water in another FSI in % expansiveness < 20 low 20-35 moderate 35-50 high > 50 very high Free Swell Index: It indicates the Expansive qualities of soil. It gives the amount of volume increase of soil on coming in contact with water DIRECT SHEAR TEST SET UP FOR TRIAXIAL COMPRESSION TEST 1.5“ DIA. 3.0“ HEIGHT (–) 4.75 mm SOIL 1.25 mm/min PROCTOR’S COMPACTION TEST Why? – To find out the Maximum Dry Density (MDD) and Optimum Moisture Content (OMC) of a soil under a particular compactive effort. Heavy compaction (5, 25, 45, 4.9) Dry Density (gm/cc) Light compaction (3, 25, 31, 2.6) MOISTURE CONTENT (%) PROCTOR’S COMPACTION APPARATUS