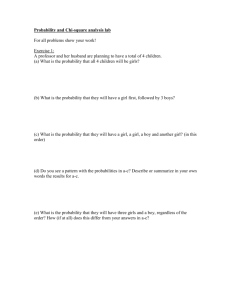

Break-even point occurs when

advertisement

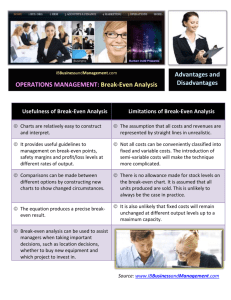

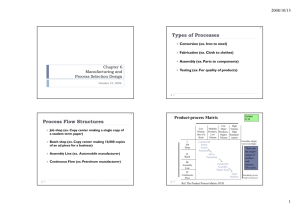

Capacity Planning Production Planning and Control Capacity The throughput, or the number of units a facility can hold, receive, store, or produce in a period of time Determines fixed costs Determines if demand will be satisfied Used to plan overtime horizon Planning Over a Time Horizon Long-range planning Add facilities Add long lead time equipment Intermediaterange planning Subcontract Add equipment Add shifts Short-range planning * Add personnel Build or use inventory * Modify capacity Schedule jobs Schedule personnel Allocate machinery Use capacity Design and Effective Capacity Design capacity is the maximum theoretical output of a system Normally expressed as a rate Effective capacity is the capacity a firm expects to achieve given current operating constraints Often lower than design capacity Utilization and Efficiency Utilization is the percent of design capacity achieved Utilization = Actual Output/Design Capacity Efficiency is the percent of effective capacity achieved Efficiency = Actual Output/Effective Capacity Bakery Example Actual production last week = 148,000 rolls Effective capacity = 175,000 rolls Design capacity = 1,200 rolls per hour Bakery operates 7 days/week, 8 hours, 3 shifts Design capacity = (7 x 3 x 8) x (1,200) = 201,600 rolls Bakery Example Actual production last week = 148,000 rolls Effective capacity = 175,000 rolls Design capacity = 1,200 rolls per hour Bakery operates 7 days/week, 8 hours, 3 shifts Design capacity = (7 x 3 x 8) x (1,200) = 201,600 rolls Utilization = 148,000/201,600 = 73.4% Bakery Example Actual production last week = 148,000 rolls Effective capacity = 175,000 rolls Design capacity = 1,200 rolls per hour Bakery operates 7 days/week, 8 hours, 3 shifts Design capacity = (7 x 3 x 8) x (1,200) = 201,600 rolls Utilization = 148,000/201,600 = 73.4% Efficiency = 148,000/175,000 = 84.6% Bakery Example Actual production last week = 148,000 rolls Effective capacity = 175,000 rolls Design capacity = 1,200 rolls per hour Bakery operates 7 days/week, 8 hours, 3 shifts Design capacity = (7 x 3 x 8) x (1,200) = 201,600 rolls Utilization = 148,000/201,600 = 73.4% Efficiency = 148,000/175,000 = 84.6% Bakery Example Actual production last week = 148,000 rolls Effective capacity = 175,000 rolls Design capacity = 1,200 rolls per hour Bakery operates 7 days/week, 8 hours, 3 shifts Efficiency = 84.6% Efficiency of new line = 75% Expected Output = (Effective Capacity)(Efficiency) = (175,000)(.75) = 131,250 rolls Capacity and Strategy Capacity decisions impact all 10 decisions of operations management as well as other functional areas of the organization Capacity decisions must be integrated into the organization’s mission and strategy Managing Demand Demand exceeds capacity Limit demand by raising prices, scheduling longer lead time Long term solution is to increase capacity Capacity exceeds demand Stimulate market Product changes Adjusting to seasonal demands Produce products with complimentary demand patterns Average unit cost (dollars per room per night) Economies and Diseconomies of Scale 25 - Room Roadside Motel 50 - Room Roadside Motel Economies of scale 25 75 - Room Roadside Motel Diseconomies of scale 50 Number of Rooms 75 Capacity Considerations Forecast demand accurately Understanding the technology and capacity increments Find the optimal operating level (volume) Build for change Tactics for Matching Capacity to Demand 1. Making staffing changes 2. Adjusting equipment and processes Purchasing additional machinery Selling or leasing out existing equipment 3. Improving methods to increase throughput 4. Redesigning the product to facilitate more throughput Complementary Demand Patterns Sales in units 4,000 – 3,000 – By combining both, the variation is reduced Snowmobile sales 2,000 – 1,000 – JFMAMJJASONDJFMAMJJASONDJ Time (months) Jet ski sales Approaches to Capacity Expansion Expected demand New capacity Expected demand Demand New capacity New capacity (c) Capacity lags demand with incremental expansion Demand (b) Leading demand with one-step expansion Expected demand (d) Attempts to have an average capacity with incremental expansion Demand Demand (a) Leading demand with incremental expansion New capacity Expected demand Break-Even Analysis Technique for evaluating process and equipment alternatives Objective is to find the point in dollars and units at which cost equals revenue Requires estimation of fixed costs, variable costs, and revenue Break-Even Analysis Fixed costs are costs that continue even if no units are produced Depreciation, taxes, debt, mortgage payments Variable costs are costs that vary with the volume of units produced Labor, materials, portion of utilities Contribution is the difference between selling price and variable cost Break-Even Analysis Assumptions Costs and revenue are linear functions Generally not the case in the real world We actually know these costs Very difficult to accomplish There is no time value of money Break-Even Analysis – Total revenue line 900 – 800 – Cost in dollars 700 – Break-even point Total cost = Total revenue Total cost line 600 – 500 – Variable cost 400 – 300 – 200 – 100 – Fixed cost | | | | | | | | | | | – 0 100 200 300 400 500 600 700 800 900 1000 1100 | Volume (units per period) Break-Even Analysis BEPx = Break-even point in units BEP$ = Break-even point in dollars P = Price per unit (after all discounts) x = Number of units produced TR = Total revenue = Px F = Fixed costs V = Variable costs TC = Total costs = F + Vx Break-even point occurs when TR = TC or Px = F + Vx BEPx = F P-V Break-Even Analysis BEPx = Break-even point in units BEP$ = Break-even point in dollars P = Price per unit (after all discounts) x = Number of units produced TR = Total revenue = Px F = Fixed costs V = Variable costs TC = Total costs = F + Vx BEP$ = BEPx P F = P P-V F = (P - V)/P F = 1 - V/P Profit = TR - TC = Px - (F + Vx) = Px - F - Vx = (P - V)x - F Break-Even Example Fixed costs = $10,000 Material = $.75/unit Direct labor = $1.50/unit Selling price = $4.00 per unit $10,000 F BEP$ = = 1 - (V/P) 1 - [(1.50 + .75)/(4.00)] Break-Even Example Fixed costs = $10,000 Direct labor = $1.50/unit Material = $.75/unit Selling price = $4.00 per unit $10,000 F BEP$ = = 1 - (V/P) 1 - [(1.50 + .75)/(4.00)] $10,000 = = $22,857.14 .4375 $10,000 F BEPx = = = 5,714 4.00 - (1.50 + .75) P-V Break-Even Example 50,000 – Revenue Dollars 40,000 – Break-even point 30,000 – Total costs 20,000 – Fixed costs 10,000 – |– | | | | | 0 2,000 4,000 6,000 8,000 10,000 Units Break-Even Example Multiproduct Case BEP$ = where V P F W i F ∑ Vi 1x (Wi) Pi = variable cost per unit = price per unit = fixed costs = percent each product is of total dollar sales = each product Multiproduct Example Fixed costs = $3,500 per month Annual Forecasted Item Price Cost Sales Units Sandwich $2.95 $1.25 7,000 Soft drink .80 .30 7,000 Baked potato 1.55 .47 5,000 Tea .75 .25 5,000 Salad bar 2.85 1.00 3,000 Multiproduct Example Fixed costs = $3,500 per month Annual Forecasted Item Price Cost Sales Units Sandwich $2.95 $1.25 7,000 Soft drink .80 .30 7,000 Baked potato 1.55 .47 Annual 5,000 Weighted % of Contribution Tea Selling Variable .75 .25Forecasted 5,000 Item (i) Price (P) Cost (V) (V/P) 1 - (V/P) Sales $ Sales (col 5 x col 7) Salad bar 2.85 1.00 3,000 Sandwich Soft drink Baked potato Tea Salad bar $2.95 .80 1.55 $1.25 .30 .47 .42 .38 .30 .58 .62 .70 $20,650 5,600 7,750 .446 .121 .167 .259 .075 .117 .75 2.85 .25 1.00 .33 .35 .67 .65 3,750 8,550 $46,300 .081 .185 1.000 .054 .120 .625 Multiproduct Example BEP = $ Fixed costs = $3,500 per month ∑ F 1 - Vi x (Wi) Pi $3,500 x Forecasted 12 Annual = = $67,200 Cost Sales Units .625 Item Price Sandwich $2.95 $1.25 7,000 $67,200 Soft drink .80 .30 7,000 Daily = = $215.38 Weighted Baked potato 1.55 .47 Annual 5,000 sales 312 days % of Contribution Tea Selling Variable .75 .25Forecasted 5,000 Item (i) Price (P) Cost (V) (V/P) 1 - (V/P) Sales $ Sales (col 5 x col 7) Salad bar 2.85 1.00 3,000 .446 x $215.38 Sandwich Soft drink Baked potato Tea Salad bar $2.95 .80 1.55 $1.25 .30 .47 .42 .38 .30 .58 .62 .70 $20,650 $2.95 5,600 7,750 .75 2.85 .25 1.00 .33 .35 .67 .65 3,750 8,550 $46,300 = 32.6 .259 33 .446 sandwiches .121 .075 .167per day .117 .081 .185 1.000 .054 .120 .625 Decision Trees and Capacity Decision -$14,000 Market favorable (.4) Market unfavorable (.6) $100,000 -$90,000 $18,000 Market favorable (.4) Medium plant Market unfavorable (.6) $60,000 -$10,000 $13,000 Market favorable (.4) Market unfavorable (.6) $40,000 -$5,000 $0 Strategy-Driven Investment Operations may be responsible for return-on-investment (ROI) Analyzing capacity alternatives should include capital investment, variable cost, cash flows, and net present value Net Present Value (NPV) P= where F P i N F (1 + i)N = future value = present value = interest rate = number of years NPV Using Factors P= where Portion of Table S7.1 F = FX N (1 + i) X = a factor from Table S7.1 defined as = 1/(1 + i)N and F = future value Year 1 2 3 4 5 5% .952 .907 .864 .823 .784 6% .943 .890 .840 .792 .747 7% .935 .873 .816 .763 .713 … 10% .909 .826 .751 .683 .621 Present Value of an Annuity An annuity is an investment which generates uniform equal payments S = RX where X = factor from Table S7.2 S = present value of a series of uniform annual receipts R = receipts that are received every year of the life of the investment Present Value of an Annuity Portion of Table S7.2 Year 1 2 3 4 5 5% .952 1.859 2.723 4.329 5.076 6% .943 1.833 2.676 3.465 4.212 7% .935 1.808 2.624 3.387 4.100 … 10% .909 1.736 2.487 3.170 3.791 Questions?