POM LECT 29 ver 2

advertisement

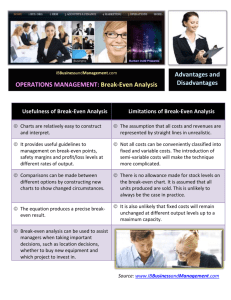

LECTURE 29 LSM733-PRODUCTION OPERATIONS MANAGEMENT By: OSMAN BIN SAIF 1 Summary of last Session Characteristics of a Waiting-Line System Arrival Characteristics Waiting-Line Characteristics Service Characteristics Measuring a Queue’s Performance Queuing Costs 2 Summary of last Session (Contd.) The Variety of Queuing Models Model A(M/M/1): Single-Channel Queuing Model with Poisson Arrivals and Exponential Service Times Model B(M/M/S): Multiple-Channel Queuing Model Model C(M/D/1): Constant-Service-Time Model Model D: Limited-Population Model 3 Summary of last Session (Contd.) Other Queuing Approaches 4 Agenda for this Session Capacity Design and Effective Capacity Capacity and Strategy Capacity Considerations Managing Demand Demand and Capacity Management in the Service Sector 5 Agenda for this Session (Contd.) Bottleneck Analysis and Theory of Constraints Process Times for Stations, Systems, and Cycles Theory of Constraints Bottleneck Management Break-Even Analysis Single-Product Case 6 Agenda for this Session (Contd.) Applying Expected Monetary Value to Capacity Decisions 7 ADDITIONAL CHAPTER: CAPACITY AND CONSTRAINT MANAGEMENT 8 Capacity The throughput, or the number of units a facility can hold, receive, store, or produce in a period of time Determines fixed costs Determines if demand will be satisfied If facilities remain idle 9 Planning Over a Time Horizon Options for Adjusting Capacity Long-range planning Add facilities Add long lead time equipment Intermediaterange planning Subcontract Add equipment Add shifts Short-range planning * Add personnel Build or use inventory * Modify capacity Schedule jobs Schedule personnel Allocate machinery Use capacity * Difficult to adjust capacity as limited options exist Figure S7.1 10 Design and Effective Capacity Design capacity is the maximum theoretical output of a system Normally expressed as a rate Effective capacity is the capacity a firm expects to achieve given current operating constraints Often lower than design capacity 11 Utilization and Efficiency Utilization is the percent of design capacity actually achieved Utilization = Actual output/Design capacity Efficiency is the percent of effective capacity actually achieved Efficiency = Actual output/Effective capacity 12 Bakery Example Actual production last week = 148,000 rolls Effective capacity = 175,000 rolls Design capacity = 1,200 rolls per hour Bakery operates 7 days/week, 3 - 8 hour shifts Design capacity = (7 x 3 x 8) x (1,200) = 201,600 rolls Bakery Example Actual production last week = 148,000 rolls Effective capacity = 175,000 rolls Design capacity = 1,200 rolls per hour Bakery operates 7 days/week, 3 - 8 hour shifts Design capacity = (7 x 3 x 8) x (1,200) = 201,600 rolls Bakery Example Actual production last week = 148,000 rolls Effective capacity = 175,000 rolls Design capacity = 1,200 rolls per hour Bakery operates 7 days/week, 3 - 8 hour shifts Design capacity = (7 x 3 x 8) x (1,200) = 201,600 rolls Utilization = 148,000/201,600 = 73.4% Bakery Example Actual production last week = 148,000 rolls Effective capacity = 175,000 rolls Design capacity = 1,200 rolls per hour Bakery operates 7 days/week, 3 - 8 hour shifts Design capacity = (7 x 3 x 8) x (1,200) = 201,600 rolls Utilization = 148,000/201,600 = 73.4% Bakery Example Actual production last week = 148,000 rolls Effective capacity = 175,000 rolls Design capacity = 1,200 rolls per hour Bakery operates 7 days/week, 3 - 8 hour shifts Design capacity = (7 x 3 x 8) x (1,200) = 201,600 rolls Utilization = 148,000/201,600 = 73.4% Efficiency = 148,000/175,000 = 84.6% Bakery Example Actual production last week = 148,000 rolls Effective capacity = 175,000 rolls Design capacity = 1,200 rolls per hour Bakery operates 7 days/week, 3 - 8 hour shifts Design capacity = (7 x 3 x 8) x (1,200) = 201,600 rolls Utilization = 148,000/201,600 = 73.4% Efficiency = 148,000/175,000 = 84.6% Bakery Example: Estimating Output of a New Facility They are considering adding a second production line and they plan to hire new employees and train them to operate this new line Effective capacity on this new line = 175,000 rolls which is the same on the first line However, due to new hires they expect that efficiency of this new line will be 75% rather than 84.6% Expected Output = (Effective Capacity)(Efficiency) = (175,000)(.75) = 131,250 rolls Capacity and Strategy Capacity decisions impact all 10 decisions of operations management as well as other functional areas of the organization Capacity decisions must be integrated into the organization’s mission and strategy Important Issues in Capacity Planning 1. Forecast demand accurately 2. Understand the technology and capacity increments 3. Find the optimum operating level (volume) 4. Build for change 21 Average unit cost (dollars per room per night) Economies and Diseconomies of Scale 25 - room roadside motel 50 - room roadside motel Economies of scale 25 75 - room roadside motel Diseconomies of scale 50 Number of Rooms 75 Figure S7.2 22 Managing Demand Demand exceeds capacity Curtail demand by raising prices, scheduling longer lead time Long term solution is to increase capacity Capacity exceeds demand Stimulate demand through price reductions Product changes Adjusting to seasonal demands Produce products with complementary demand patterns 23 Complementary Demand Patterns Sales in units 4,000 – 3,000 – 2,000 – 1,000 – JFMAMJJASONDJFMAMJJASONDJ Time (months) Jet ski engine sales Figure S7.3 24 Complementary Demand Patterns Sales in units 4,000 – 3,000 – Snowmobile motor sales 2,000 – 1,000 – JFMAMJJASONDJFMAMJJASONDJ Time (months) Jet ski engine sales Figure S7.3 25 Complementary Demand Patterns Sales in units 4,000 – 3,000 – Combining both demand patterns reduces the variation Snowmobile motor sales 2,000 – 1,000 – JFMAMJJASONDJFMAMJJASONDJ Time (months) Jet ski engine sales Figure S7.3 26 Tactics for Matching Capacity to Demand 1. Increasing/decreasing employees and shifts 2. Adjusting equipment Purchasing additional machinery Selling or leasing out existing equipment 3. Improving processes to increase throughput 4. Redesigning products to facilitate more throughput 5. Adding process flexibility to meet changing product preferences 6. Closing facilities 27 Demand and Capacity Management in the Service Sector Demand management (scheduling customers) Appointment, reservations, FCFS rule Capacity management (scheduling workforce) Full time, temporary, part-time staff 28 Bottleneck Analysis and Theory of Constraints Capacity analysis determines the throughput capacity of workstations in a system A bottleneck has the lowest effective capacity in a system A bottleneck is a limiting factor or constraint 29 Theory of Constraints Five-step process for recognizing and managing limitations Step 1: Identify the constraint Step 2: Develop a plan for overcoming the constraints Step 3: Focus resources on accomplishing Step 2 Step 4: Reduce the effects of constraints by offloading work or expanding capability Step 5: Once overcome, go back to Step 1 and find new constraints 30 Bottleneck Management 1. Release work orders to the system at the pace of set by the bottleneck 2. Lost time at the bottleneck represents lost time for the whole system 3. Increasing the capacity of a non-bottleneck station is a mirage 4. Increasing the capacity of a bottleneck increases the capacity of the whole system 31 Process Times for Stations, Systems, and Cycles The process time of a station is the time to produce a unit at that single workstation The process time of a system is the time of the longest process in the system … the bottleneck The system capacity is the inverse of the system process time The process cycle time is the total time through the longest path in the system 32 A Three-Station Assembly Line Process time of stations: 2, 4 and 3 min/unit Process time for the system: 4 min/unit Process Cycle Time= 2 + 4 + 3 = 9 min/unit System Capacity = ¼*60(min)= 15 units/hour A B C 2 min/unit 4 min/unit 3 min/unit Figure S7.4 33 Capacity Analysis EXAMPLE Two identical sandwich lines Lines have two workers and three operations All completed sandwiches are wrapped Bread 15 sec/sandwich Fill 20 sec/sandwich Toast 40 sec/sandwich Order Wrap 30 sec/sandwich 37.5 sec/sandwich Bread 15 sec/sandwich Fill 20 sec/sandwich Toast 40 sec/sandwich 34 Capacity Analysis Bread Order 30 sec 15 sec Bread 15 sec Fill Toast 20 sec 40 sec Fill Toast 20 sec 40 sec Wrap 37.5 sec It seems that the toast work station has the longest processing time – 40 seconds, but the two lines work in parallel and each deliver a sandwich every 40 seconds so the process time of the toast work station is 40/2 = 20 seconds. So process time of five stations are 30, 15, 20, 40 and 37.5 sec., respectively. With 37.5 seconds, wrapping station has the longest processing time and it is the bottleneck. So process time of the system is 37.5 sec. System capacity per hour is (1/37.5)*3,600 seconds = 96 sandwiches per hour Process cycle time is 30 + 15 + 20 + 40 + 37.5 = 142.5 seconds 35 Capacity Analysis Example Standard process for cleaning teeth Cleaning and examining X-rays can happen simultaneously Hygienist Cleans the teeth Customer Checks in A Lab Ass. Takes X-ray A Lab Ass Develops X-ray 2 min/unit 2 min/unit 4 min/unit 24 min/unit Dentist re-processes Dentist Examines X-ray and processes 8 min/unit Customer pays 6 min/unit 5 min/unit 36 Capacity Analysis Cleaning Check in Takes X-ray Develops X-ray 24 min/unit 2 min/unit 2 min/unit 4 min/unit X-ray exam Dentist Check out 8 min/unit 6 min/unit 5 min/unit All possible paths must be compared Cleaning path is 2 + 2 + 4 + 24 + 8 + 6 = 46 minutes, X-ray exam path is 2 + 2 + 4 + 5 + 8 + 6 = 27 minutes Longest path involves the hygienist cleaning the teeth, so the process cycle time is 46 min. The patient will be out of door after 46 min. Bottleneck is the hygienist at 24 minutes which is the process time of the system System capacity is (1/24)*60 min = 2.5 patients/per hour 37 Break-Even Analysis Technique for evaluating process and equipment alternatives Objective is to find the break-even point in dollars and in units at which cost equals revenue Requires estimation of fixed costs, variable costs, and revenue 38 Break-Even Analysis Fixed costs are costs that continue even if no units are produced Depreciation, taxes, debt, mortgage payments Variable costs are costs that vary with the volume of units produced Labor, materials, portion of utilities Contribution is the difference between selling price and variable cost 39 Break-Even Analysis Assumptions Costs and revenue are linear functions Generally not the case in the real world We actually know these costs Very difficult to verify Time value of money is often ignored 40 Break-Even Analysis – Total revenue line 900 – 800 – 700 – Cost in dollars Total cost line Break-even point Total cost = Total revenue 600 – 500 – Variable cost 400 – 300 – 200 – 100 – – 0 | Figure S7.5 Fixed cost | | | | | | | | | | | 100 200 300 400 500 600 700 800 900 1000 1100 Volume (units per period) 41 Break-Even Analysis BEPx = break-even point in units BEP$ = break-even point in dollars P = price per unit (after all discounts) x = number of units produced TR F V TC = = = = total revenue = Px fixed costs variable cost per unit total costs = F + Vx Break-even point occurs when TR = TC or Px = F + Vx BEPx = F P-V 42 Break-Even Analysis BEPx = break-even point in units BEP$ = break-even point in dollars P = price per unit (after all discounts) BEP$ = BEPx P F = P P-V F = (P - V)/P F = 1 - V/P x = number of units produced TR F V TC = = = = total revenue = Px fixed costs variable cost per unit total costs = F + Vx Profit = TR - TC = Px - (F + Vx) = Px - F - Vx = (P - V)x - F 43 Break-Even Example Fixed costs = $10,000 Direct labor = $1.50/unit BEP$ = Material = $.75/unit Selling price = $4.00 per unit F 1 - (V/P) = $10,000 1 - [(1.50 + .75)/(4.00)] 44 Break-Even Example Fixed costs = $10,000 Direct labor = $1.50/unit F 1 - (V/P) BEP$ = = BEPx = Material = $.75/unit Selling price = $4.00 per unit = $10,000 .4375 F P-V $10,000 1 - [(1.50 + .75)/(4.00)] = $22,857.14 = $10,000 4.00 - (1.50 + .75) = 5,714 45 Break-Even Example 50,000 – Revenue 40,000 – Break-even point Dollars 30,000 – Total costs 20,000 – Fixed costs 10,000 – |– | | | | | 0 2,000 4,000 6,000 8,000 10,000 Units 46 Expected Monetary Value (EMV) and Capacity Decisions Determine states of nature Future demand Market favorability Analyzed using decision trees Hospital supply company Four alternatives for capacity expansion 47 Expected Monetary Value (EMV) and Capacity Decisions Market favorable (.4) Market unfavorable (.6) Market favorable (.4) Medium plant Market unfavorable (.6) Market favorable (.4) Market unfavorable (.6) $100,000 -$90,000 $60,000 -$10,000 $40,000 -$5,000 $0 48 Expected Monetary Value (EMV) and Capacity Decisions Market favorable (.4) Market unfavorable (.6) Market favorable (.4) Medium plant Large Plant EMV = (.4)($100,000) + (.6)(-$90,000) EMV = -$14,000 Market unfavorable (.6) Market favorable (.4) Market unfavorable (.6) $100,000 -$90,000 $60,000 -$10,000 $40,000 -$5,000 $0 49 Expected Monetary Value (EMV) and Capacity Decisions -$14,000 Market favorable (.4) Market unfavorable (.6) $100,000 -$90,000 $18,000 Market favorable (.4) Medium plant Market unfavorable (.6) $60,000 -$10,000 $13,000 Market favorable (.4) Market unfavorable (.6) $40,000 -$5,000 $0 50 Summary of the Session Capacity Design and Effective Capacity Capacity and Strategy Capacity Considerations Managing Demand Demand and Capacity Management in the Service Sector 51 Summary of the Session(Contd.) Bottleneck Analysis and Theory of Constraints Process Times for Stations, Systems, and Cycles Theory of Constraints Bottleneck Management Break-Even Analysis Single-Product Case 52 Summary of the Session (Contd.) Applying Expected Monetary Value to Capacity Decisions 53 THANK YOU 54