The Toyota Way - Snyder Consulting & Associates

advertisement

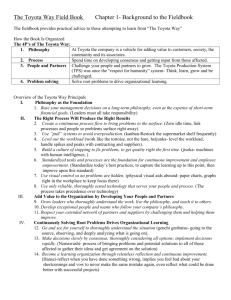

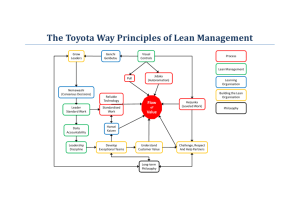

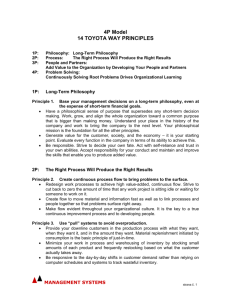

The Toyota Way by Jeffrey Liker 14 Management Principles from the World’s Greatest Manufacturer Tedd Snyder Snyder Consulting & Associates tfsnyder@teddsnyder.com MAQIN Lean and Six Sigma Special Interest Group May 19, 2004 Toyota History 1894 - Sakichi Toyoda, a tinkerer and inventor, begins making manual looms. 1926 – Toyoda opens Toyoda Automatic Loom Works. He later invents looms that stop automatically when thread breaks (jidoka). 1937 - Kiichiro Toyoda, an engineer, opens Toyota Motor Company. Visits Ford and GM during the 30s. 1945 - Toyoda challenges company to catch up to US in 3 years. 1948 - Toyota’s debt is 8 times its capital value. 1950s –Toyota studies US plants, including Ford, and supermarkets during a 12 week study visit. They see little improvement since his trip in the 30s but use supermarkets as a model for just-in-time production. The Toyota Approach : 4Ps Continuously solving root PROBLEMS Principles 12-14 Add value to the organization by developing your PEOPLE and PARTNERS Principles 9-11 The right PROCESS will produce the right results Principles 2-8 Long Term PHILOSOPHY Principle 1 Toyota’s 14 Management Principles 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. Base your management decisions on a long term philosophy, even at the expense of short term financial goals. Create continuous process flow to bring problems to the surface. Use “pull” systems to avoid overproduction. Level out workload (heijunka). Build a culture of stopping to fix problems, to get quality right the first time. Standardized tasks are the foundation for continuous improvement and employee empowerment Use visual control so no problems are hidden. Use only reliable thoroughly tested technology that serves your people and processes. Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others Develop exceptional people and teams who follow your company’s philosophy Respect you extended network of partners and suppliers by challenging them improve. Go and see for yourself to thoroughly understand the situation. Make decisions slowly by consensus, thoroughly considering all options; implement decisions rapidly Become a learning organization through relentless reflection (hansei) and continuous improvement (kaizen) Principle 1: Base your management decisions on a long term philosophy, even at the expense of short term financial goals Have a sense of purpose that supercedes any short term decision making. Work, grow, align the organization toward a purpose greater than “making money.” Understand your place in the history of the company and work to bring the company to the next level. Generate value for the customer, society and the economy. Evaluate every function in the company in terms of its ability to achieve this. Be responsible. Strive to decide your own fate. Act with self reliance and trust in your own abilities. Accept responsibility for your conduct and maintain and improve the skills that enable you to produce added value. Principle 2: Create continuous process flow to bring problems to the surface Redesign processes to achieve high value added, continuous flow. Create flow to move material and information fast as well as to link processes and people together so that problems surface right away. Make flow evident throughout your organizational culture. Case Study – Navy yard job summaries Lead time reduced 63% Distance paperwork traveled reduced 55-92% Number of steps reduced by 67% Handoffs reduced by 80% Principle 3: Use “pull” systems to avoid overproduction Provide your downstream customers in the process with what they want, when they want it, and in the amount that they want. Toyota studied US supermarkets in the 50’s Pull vs Push (Production Schedule) Material replenishment initiated by consumption is the basis for just-in-time. Just-in Time - an organized system of inventory buffers. Examples- filling your gas tank, office supplies. Kanban - sign, signboard, doorplate, poster, billboard, card…signal “Flow (one piece) where you can and pull where you must.” - Rother and Shook in “Learning to See” Scheduling still happens, but keep it short (days vs months) Principle 4: Level out workload (heijunka) Eliminating Muda is just one third of the equation for making lean successful. Eliminating Muri and eliminating Mura in production are just as important. Muda (waste) Transportation, Inventory,Movement Waiting, Overproduction, Overprocessing, Defects + Unused employee abilities Muri (overwork), Mura (inconsistency),Heijunka (evenness) AAABBBCCC to ABCABCABC Case study- Gutter manufacturer Lead time reduced by 40% Changeover time reduced by 70% WIP reduced by 40% Inventory obsolescence reduced by 60% Principle 5: Build a culture of stopping to fix problems, to get quality right the first time Quality at the source Jidoka – autonomation Andon – signal for help Yellow, then red Team leader fix, figure, pull Segmented assembly line with buffer inventory “Freshman job” Takt = 57 Touch = 44.7 Poke yoke – “get rid of mistakes” mistake avoidance (example-cotter pin/light curtain) (avoid easy mistakes) Administrative approaches –standardized work and checklists (pilots) (engineering forced to consider alternatives) Toyota’s quality process 1. 2. 3. 4. Go and see Understand the situation One piece flow or andon Ask why 5 times Principle 6: Standardized tasks are the foundation for continuous improvement and employee empowerment Standardized work is not the end result, the “one best way,” it is the beginning of improvement. Use stable, repeatable methods everywhere to maintain the predictability, timing, and regular output of your processes. (This also helps to manage them). It is the foundation of flow and pull. Standardized work consists of three elements Takt time Sequence of the process Amount of stock on hand Capture the accumulated learning about a process by standardizing the current best practices. Allow creative and individual expression to improve upon the standard; then incorporate it into the new standard. Principle 7: Use visual control so no problems are hidden Visual Control – The ability to see abnormalities at a glance. Example - Ask a coworker to see a specific document, item, or something on their computer or the company’s intranet. 5S Sort Straighten Shine Standardize Sustain Example – email audits Process Control Boards (daily goals, takt rate, manpower, current status throughout the day) Reduce your reports to one piece of paper whenever possible. E.g. A3 (11x17) Reports (Storyboards) A4 (8 ½ x 11)next! Principle 8: Use only reliable thoroughly tested technology that serves your people and processes Use technology to support people, not to replace people. Conduct actual tests before adopting new technology in business processes, manufacturing systems, or products. Reject technologies that conflict with your culture or that might disrupt stability, reliability, and predictability. Encourage your people to consider new technologies when looking into new approaches to work. Quickly implement a thoroughly considered technology if it has been proven in trials and it can improve the flow of your processes. Principle 9: Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others Grow leaders from within rather than buying them from outside. (This is an example of applying Heijunka)…or constancy of purpose. Leaders must be role models of the company’s philosophy and way of doing business. A good leader must understand the daily work in great detail so they can be the best teacher of your company’s philosophy. “Before we make cars (monozukuri), we make people (hito- zukuri).” Principle 10: Develop exceptional people and teams who follow your company’s philosophy Create a strong, stable culture in which company values and beliefs are widely shared and lived out over a period of many years. Respect for Humanity system Uses both intrinsic and extrinsic approaches to motivation Train exceptional individuals and teams to work within the corporate philosophy to achieve exceptional results. Balance between teamwork and excellent individual work Use cross functional teams to improve quality and productivity and enhance flow by solving problems. Make an ongoing effort to teach individuals how to work together as team toward common goals. Teamwork is something that has to be learned. Principle 11: Respect you extended network of partners and suppliers by challenging them improve Have respect for your partners and suppliers and treat them as an extension of your company. Challenge your partners to grow and develop. It shows that you value them. Set challenging targets and assist your partners in achieving them. (e.g. John Deere, Harley Davidson) Principle 12: Go and see for yourself to thoroughly understand the situation Genchi (actual location) genbutsu (actual material or product)…also known as going to the gemba. Example-Siena chief engineer drives in 50 states, 13 provinces and territories and Mexico Improvements include turning radius, wind stability, drift, cup holders and trays “Common sense will tell you the answer, but collecting data (and then understanding the facts) will tell you whether your common sense was correct.” The Ohno circle – He asked an engineer to stand and observe an operation…for 8 hours! “The Geography of Thought: How Asians and Westerners Think Differently and Why” by Richard Nisbett Westerners see things Easterners see things and relationships Language? Hourensou- to report, to update periodically, to consult or advise Genchi genbutsu for executives (coordinated reporting) Principle 13: Make decisions slowly by consensus, thoroughly considering all options; implement decisions rapidly Given a year to implement a project… Western – typically 3 months planning, 9 months implementing and correcting (Tedd’s example-in a class exercise, I assign 15 min. to “plan” and 45 minutes to “do.” Participants never use the full 15 minutes, even since I’ve reinforced the importance of this time.) Toyota – typically 10 months planning, pilot, implement flawlessly Toyota decision making Find out what is really going on, including genchi genbutsu Understanding underlying causes that explain surface appearances – asking “Why?” five times Broadly considering alternative solutions and developing a detailed rationale for the preferred solution. 1. 2. 3. – – Building consensus within the team, including employees and outside partners. 4. – 5. What alternatives have you considered? How does this solution compare with those alternatives? Nemawashi –the process of discussing problems and potential solutions with all those affected, to collect their ideas and get agreement on a path forward. e.g. tollgate review Using very efficient communication vehicles to do 1-4, preferably one side of one page (e.g. one page 7 step storyboards) Principle 14: Become a learning organization through relentless reflection (hansei) and continuous improvement (kaizen) “Many people are surprised when I give talks and tell them that Toyota doesn’t have a Six Sigma program. Six Sigma is based on complex statistical analysis tools. People want to know how Toyota achieves such high levels of quality without the quality tools of Six Sigma. You can find an example of every Six Sigma tool in use somewhere in Toyota at some time. Yet most problems do not call for complex statistical analysis, but instead require painstaking, detailed problem solving. This requires a level of detailed thinking and analysis that is all too absent from most companies in day-to-day activity. It is a matter of discipline, attitude, and culture.” Jeffrey Liker Principle 14: Become a learning organization through relentless reflection (hansei) and continuous improvement (kaizen) 7 step problem solving method Problem solving is 20% tools and 80% thinking. Hansei – loosely “reflection” or lessons learned Hansei kai – reflection meetings “Please do the Hansei.” 1. Feel sorry. 2. Create a plan to solve the problem. 3. Sincerely believe you will not make this mistake again. Without Hansei, it is impossible to have kaizen. e.g. DMAIC tollgates No magic metrics Policy Deployment In Closing… “We place the highest value on actual implementation and taking action.” Fujio Cho President, Toyota Motor Corporation 2002