The Toyota Way to No.1

advertisement

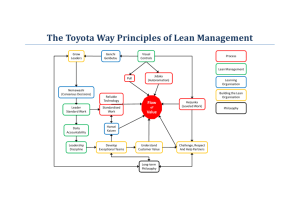

The Toyota Way How They Became #1 Presented by Adrienne Larson What is The Toyota Way? Values and Conduct: Challenge Kaizen (improvement) Genchi genbutsu (go and see) Respect Teamwork The Four Main Components Long-term thinking as a basis for management decisions A process for problem-solving Adding value to the organization by developing its people Recognizing that continuously solving root problems drives organizational learning Is The Toyota Way the reason for their competitive advantage? A brief look at their history: Founded in 1937 as a auto manufacturer Studied USA companies 1982 Took over old GM plant Began selling cars in USA in late 80’s 2007 became the #1 auto manufacture in USA Their Competitive advantage was evident in 2007 Passed the top Three in auto sales #1 car in America was the Camry Entering the Full size truck market #1 fuel economy in car All aspect of lean manufacturing , just in time inventory, and TQM practiced No product recalls Does Toyota still have the competitive advantage in 2013? To answer that we need to look at what has happened to the company since 2007 The Bad News Since 2007……. U.S economy in trouble Toyota had major recalls in 2009 and 2010 Slowed truck sales for Tundra Camry acceleration 9million recall due to bad window switch largest in auto history Lost credibility, closed plants for 11 days 2011Natural disasters caused major production problems Went from 8th (2005)on Forbes list to 55th (2011) Did not maintain consecutively #1 auto manufacture The good news since 2007.... 216 billion in revenue as of May 2013 Top auto manufacture in 2012 Largest hybrid car manufacture globally Second behind Chevy Volt in plug-in hybrid in U.S sales Ended GM partnership 2009 Working towards image of “An American Company” HR issues in 2007 Employing Need to be perfect at all times Culture U.S. the Toyota Way globally of GROUPTHINK competition lacking HR issues in 2013 Getting beyond culture of groupthink but still applying their Toyota way as explained : Base your management decisions on a long-term philosophy, even at the expense of short-term goals Create continuous process flow to bring problems to the surface Use "pull" systems to avoid overproduction Level out the workload Build a culture of stopping to fix problems, to get quality right the first time Standardized tasks are the foundation for continuous improvement and employee empowerment Use visual control so no problems are hidden Use only reliable, thoroughly tested technology that serves your people and processes Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others Develop exceptional people and teams who follow your company’s philosophy Respect your extended network of partners and suppliers by challenging them and helping them improve Go and see for yourself to thoroughly understand the situation (genchi genbutsu) Make decisions slowly by consensus, thoroughly considering all options; implement decisions rapidly Become a learning organization through relentless reflection and continuous improvement Top three issues for HR Build a culture of stopping to fix problems, to get quality right the first time Never let mass recalls to happen again Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others Can American workers rise to this standard? Make decisions slowly by consensus, thoroughly considering all options; implement decisions rapidly The big three American auto manufacturer are giving chase through solid competition Thank You are there Any Questions? Work sited: Wikipedia Case study The Toyota Way PDF][pdf] toyota global visionwww.toyotaglobal.com/company/message_from.../pre sident110309.pdfToyota will lead the way to the future of mobility, ... We will meet challenging goals by engaging the talent and ... Boost human resource development.