Information Systems: A Manager's Guide to Harnessing Technology

advertisement

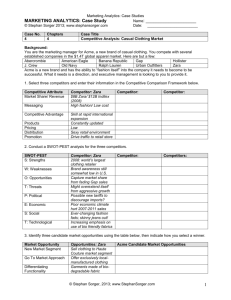

Information Systems: A Manager’s Guide to Harnessing Technology 3-1 This work is licensed under the Creative Commons Attribution-Noncommercial-Share Alike 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/or send a letter to Creative Commons, 171 Second Street, Suite 300, San Francisco, California, 94105, USA 3-2 Chapter 3 Zara: Fast Fashion from Savvy Systems A Zara store in Manhattan: Controlling the supply chain is key, Jennifer S. Altman 3-3 "you need to have five fingers touching the factory and Hve touching the customer." Translation: Control what happens to your product until the customer buys it. CEO Amancio Ortega 2-4 Learning Objectives • Understand how Zara’s parent company, Inditex, leveraged a technologyenabled strategy to become the world’s largest fashion retailer • Contrast Zara’s approach with the conventional wisdom in fashion retail examining how the firm’s strategic use of information technology influences design and product offerings, manufacturing, inventory, logistics, marketing, and ultimately profitability 3-5 Learning Objectives • Detail how Zara’s approach counteracts specific factors that Gap has struggled with for over a decade • Identify the environmental threats that Zara is likely to face and consider options available to the firm for addressing these threats 3-6 Table 3.1 - Gap versus Inditex at a Glance 3-7 Why Study Zara? • To understand and appreciate : – The counterintuitive and successful strategy of Zara – The technology, which has made all of this possible 3-8 Gap: An Icon in Crisis • Micky Drexler, the iconic CEO, helped turn Gap’s button-down shirts and khakis into America’s business casual uniform • Drexler’s team had spot-on tastes throughout the 1990s • When sales declined in the early 2000s, Drexler tried to revitalize the brand by filling the stores with teenage apparels • This shift sent Gap’s mainstay customers to retailers that easily copied the styles that Gap had made classic 3-9 Gap: An Icon in Crisis • Gap’s same-store sales declined for twenty-nine months straight, profits vanished • Paul Pressler, the new CEO shut down hundreds of stores, but it did not help due to bad bets on colors and styles • The marketing model used by Gap to draw customers in via big-budget television promotion had collapsed • In January 2007, Pressler resigned 3-10 Contract Manufacturing: Lower Costs at What Cost? • Conventional wisdom suggests that leveraging cheap contract manufacturing in developing countries can keep the cost of goods low – Contract manufacturing: Involves outsourcing production to third-party firms • Firms that use contract manufacturers don’t own the plants or directly employ the workers who produce the requested goods • Firms can lower prices and sell more product or maintain higher profit margins 3-11 Contract Manufacturing: Lower Costs at What Cost? • The downside of contract manufacturing – In order to have the low-cost bid, contract firms: • Skimp on safety • Ignore environmental concerns • Employ child labor • Engage in some ghastly practices 3-12 Contract Manufacturing: Lower Costs at What Cost? • Firms that fail to adequately ensure their products are made under acceptable labor conditions risk a brand-damaging backlash that may: – Turn off customers – Repel new hires – Leave current staff feeling betrayed 3-13 Don’t Guess, Gather Data • To make sure that the stores carry the kinds of products customers want, Zara managers ask the customers • Zara’s store managers are armed with personal digital assistants (PDAs) that can be used to: – Gather customer input – Chat up with customers to gain feedback on what they’d like to see more of • Incentives for success—as much as 70 percent of salaries can come from commissions 3-14 Don’t Guess, Gather Data • Staff also checks for customer preferences by looking at unsold items • PDAs are linked to the store’s point-of-sale (POS) system • Point-of-sale (POS) system: A transaction process that captures customer purchase information, showing how garments rank by sales • Managers can send updates that combine the hard data captured at the cash register with insights (soft data) on what customers would like to see 3-15 Don’t Guess, Gather Data • All of this valuable data allows the firm to plan styles and issue rebuy orders based on feedback rather than hunches and guesswork • The goal is to improve the frequency and quality of decisions made by the design and planning teams 3-16 Design • Zara designs follow evidence of customer demand • Zara design staff consists of young and fresh designers from design school • Teams are regularly rotated to: – Cross-pollinate experience – Encourage innovation 3-17 Manufacturing and Logistics • The average time for a Zara concept to go from idea to appearance in store is fifteen days versus their rivals who receive new styles once or twice a season • The firm is able to be so responsive through: – A competitor-crushing combination of vertical integration and technologyorchestrated coordination of suppliers – Just-in-time manufacturing – Finely tuned logistics 3-18 Manufacturing and Logistics • Vertical integration: When a single firm owns several layers in its value chain • Value chain: The set of interdependent activities that bring a product or service to market • Nearly 60 percent of Zara’s merchandise is produced in-house, with an eye on leveraging technology in areas that: – Speed up complex tasks – Lower cycle time – Reduce error 3-19 Manufacturing and Logistics • Inventory optimization models ensure that each store is stocked with just what it needs • Zara leverages contract manufacturers to produce staple items with longer shelf lives, which account for only about one-eighth of dollar volume 3-20 Manufacturing and Logistics • Ceiling-mounted racks and customized sorting machines patterned on equipment used by overnight parcel services and Toyota-designed logistics, whisk items from factories to staging areas for each store • Clothes are ironed in advance and packed on hangers, with security and price tags affixed • Trucks serve destinations that can be reached overnight, while chartered cargo flights serve farther destinations within forty-eight hours • Zara is also a pioneer in going green – Introduction of biodiesel for the firm’s trucking fleet 3-21 Stores • Running out of bestsellers at Zara delivers several benefits: – Allows the firm to cultivate the exclusivity of its offerings – Encourage customers to buy right away and at full price – Encourages customers to visit often – Reduces the rate of failed product introductions 3-22 Technology ≠ Systems. Just Ask Prada • Zara’s IT expenditure is less than one-fourth the fashion industry average • Zara excels by targeting technology investment at the points in its value chain where it will have the most significant impact • Zara makes sure that every dollar spent on tech has a payoff 3-23 Technology ≠ Systems. Just Ask Prada • The Prada example offers critical lessons for managers: – Getting the right mix of the following five components is critical to executing a flawless information system rollout: • Hardware • Software • Data • Procedures • People – Financial considerations should forecast the return on investment (ROI) of any effort – Designers need to thoroughly test the system before deployment 3-24 Moving Forward • Zara’s value chain is difficult to copy, but it still has challenges to face • Limitations of Zara’s Spain-centric, just-in-time manufacturing model: – If problems occur in northern Spain, Zara has no other fall back – The firm is potentially more susceptible to financial vulnerabilities as the Euro has strengthened relative to the dollar – Rising transportation costs • Zara’s financial performance can also be impacted by broader economic conditions 3-25 Moving Forward • Zara’s value chain is difficult to copy; but it is not invulnerable, nor is future dominance guaranteed • Zara’s management must – Have an understanding of how information systems can enable winning strategies – Scan the state of the market and the state of the art in technology, looking for new opportunities and remaining aware of impending threats 3-26 Let numbers speak for themselves • • • • • • The chain’s profitability is among the highest in the industry. “the most innovative and devastating retailer in the world.” High fashion but are comparatively inexpensive (average item price is $27) Legions of fans eagerly await “Z-day,” the twice-weekly inventory delivery. Managers are motivated because as much as 70 percent of salaries can come from commissions. Postponement strategy: Roughly half of the cloth arrives undyed so the firm can respond as any midseason fashion shifts occur. http://en.wikipedia.org/wiki/Postponement (e.g., Acer PC CPU, Beer labeling) 2-27 • • • Clothes are ironed in advance and packed on hangers, with security and price tags affixed. Store staff regain as much as three hours in prime selling time (per day?). While running out of bestsellers might be seen as a disaster at most retailers, at Zara the practice delivers several benefits. 2-28 Attributes Competitors Zara New Items Designed 2,000~4,000 (H&M,Gap) 30,000 From concepts to products 3~5 months (H&M), 6 months (Gap) , 9 months (others) 15 days Manufacturing No factory (H&M) 60% produced in house Batch size Hugh batch size “everything is the same” (Gap) Small batches “You’ll never end up looking like someone else.” average markdown ratio approximately 50% 15% (85% full price) # of store visit per year 3 17 Marketing /Revenue ratio 3.5% 0.3% Failed product introductions 10% 1% gross margins 56.8% 37.5% IT Investment Stores ¼ of the industry average 3,076 stores WW with 2,551 in US (Gap) 3,900 stores across 70 countries. 2-29 Technologies Deployed and Information Gathered • • • • • • personal digital assistants (PDAs)—handheld computing devices PDAs are also linked to the store’s point-of-sale (POS) system Looking for evidence in the piles of unsold items that customers tried on but didn’t buy. Zara designs follow evidence of customer demand. Computer-controlled machine cutting tools “The success of the model lies in being able to adapt what you’re offering in the shortest time possible to what clients want. For Inditex, time is the principal factor to take into account, more so than the costs of production.” 2-30 • • • • • • • • Close the communication loop: Customer Store Manager/staff market specialists/designer Production staff Buyer Subcontractor Warehouse managers/distributor Separate design, sales, and procurement and production planning staffs are dedicated to each clothing line (Men, women, and children). Zara's cadre of 200 designers sits right in the midst of the production process End-to-end control of supply chain. Reduce the supply chain cycle time: Speed and responsiveness Supply chain flexibility: Most garments come with five to six colors and five to seven sizes, Zara's system has to deal with something in the realm of 300,000 new stock-keeping units (SKUs), on average, every year. 2-31 2-32 Bullwhip Effect in Supply Chain Main information flow Physical flow ERP Demand-Driven Supply Chain SCM SCM CRM Bullwhip effect -the tendency of supply chains (and all open-loop information systems) to amplify small disturbances. Increasing Variability of Orders up the Supply Chain The Bullwhip Effect in Supply Chains, Hau L. Lee, V. Padmanabhan and Seungjin Whang, Sloan Management Review, April 15, 1997 http://en.wikipedia.org/wiki/Zara_(clothing) http://www.zara.com/#/en_GB/catalogue/woman/ http://www.zara-clothing.net/zara-basic/