L7b-1

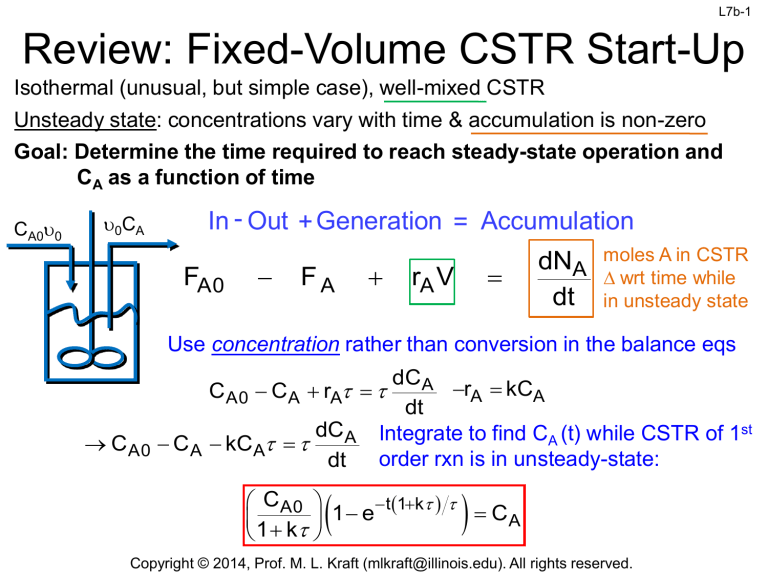

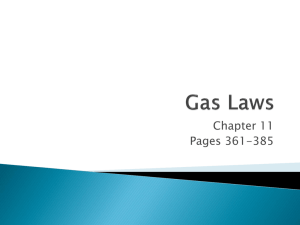

Review: Fixed-Volume CSTR Start-Up

Isothermal (unusual, but simple case), well-mixed CSTR

Unsteady state: concentrations vary with time & accumulation is non-zero

Goal: Determine the time required to reach steady-state operation and

CA as a function of time

CA0u0

u0CA

In - Out + Generation = Accumulation

FA0

FA

rA V

dNA

dt

moles A in CSTR

D wrt time while

in unsteady state

Use concentration rather than conversion in the balance eqs

dC A

rA kCA

C A0 CA rA

dt

dCA Integrate to find CA (t) while CSTR of 1st

CA0 CA kCA

order rxn is in unsteady-state:

dt

CA0

t 1k

1

e

CA

1 k

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

L7b-2

Review: Time to Reach Steady-State

C A0

At steady state, CA0

t 1k

CAS

1 e

CA

1 k

t is large and: 1 k

0

In the unsteady state, CA0

CA0

t s 1k

0.99

1 e

when CA = 0.99CAS:

1

k

1 k

4.6

t time to reach 99% (CA = 0.99CAS) of

steady-state concentration in terms of k

1 k

When k is very small

t 4.6

(slow rxn), 1>>k: s

When k is very big

(fast rxn), 1<<k

63% of the steady-state

concentration is achieved at: 1 k

ts

4.6

k

CA = 0.63CAS

99% of the steady-state

4.6

concentration is achieved at:

1 k

CA 0.99CAS

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

Review: Enhanced Yield in SemiBatch Reactor

F

Semi-batch

L7b-3

D

FB

A

V0 + u0t

A+B

A+B

→P

V0

V0 + u0t

A+B⇌

C+D

V0 - u0t

Vf

Scenario 1 shown in blue. Scenario 2 shown in red.

Scenario 1: Enhance selectivity of desired product over undesired side product

Higher concentrations of A favor formation of the desired product

Higher concentrations of B favor formation of the undesired side product

Scenario 2: Improve the product yield obtained from a reversible reaction

A l B l

C l D g

Allowing D(g) to bubble out of solution pushes equilibrium towards completion

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

CBu0

Review: Mole Balance on A for

Semi-Batch Reactor

L7b-4

Goal: Find how CA D with time (assume reactor is well-mixed)

In - Out + Generation =

Accumulation

dNA

0 0 rA V

dt

Use whatever units are most convenient (NA, CA, XA, etc)

V0 + u0t

Convert NA to CA using:

NA

dCA V r V V dCA C dV

CA NA CA V

A

A

rA V

dt

dt

V

dt

Reactor volume balance:

In - Out + Generation = Accumulation

d V u = u0

dV

u0

0u0 0 0

V0 u0t V

0

dt

dt

rA V V

dCA

C Au0

dt

Rearrange to get in

terms of dCA/dt

rA

CAu0 dCA

V

dt

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

Review: Mole Balance on B in

Semi-Batch Reactor

C u

L7b-5

Goal: Find how CB D with time (assume reactor is well-mixed)

B 0

Mole balance on B:

In - Out + Generation =

FB0

V0 + u0t

0 + rB V

dNB

rB V FB0

dt

Accumulation

dNB

dt

NB CB V

dC

d

dV

CB V rB V CB0u0 CB V B rB V CB0u0

dt

dt

dt

dV

u0

Substitute

dt

dC

CBu0 V B rB V CB0u0 Rearrange to get in terms of dCB/dt

dt

u0 CB0 CB

dCB

rB

dt

V

Balance on B

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

L7b-6

CBu0

Review: Semi-Batch Mole

Balances in Terms of NA

Goal: Find how NA & NB D with time (reactor is well-mixed)

In - Out + Generation = Accumulation

0

0

rA V

dNA

dt

dNA

rA V

dt

V0 + u0t

N

C

Substitute: -rA = kACACB and V0 u0 t V and

V

NANB

dNA

dNA

NANB

then rA k

r

V

k

A

2

dt

dt

V0 u0 t

V u t

0

0

NB comes from basic mole balance:

dNB

NANB

dNB

k

FB0

rA V FB0

dt

V0 u0 t

dt

The design eq in terms of XA can be messy. Sometimes it gives a single

equation when using Nj or Cj gives multiple reactor designs

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

X=0

P0 = 20 atm

PBR, 1000 kg cat

X=?

P = ? atm

2A→B -rA = kCA2

α = 0.0008/kg

k=0.1 dm6/mol∙min∙kg cat at 300 K

FA0 = 10 mol min

1.

Mole balance

2.

Rate law

dX A

r 'A

dW

rA kC A 2

FA0

3. Stoichiometry (put CA C A

in terms of X)

4. Combine

C A0 1 X A P

1 X A P0

dX A

dW

5. Relate P/P0 to W

L7b-7

What conversion and P is

measured at the outlet of the

PBR? The rxn is isothermal at 300

K, assume ideal gas behavior, and

the feed contains pure A (g).

dX A

dW

k C A02

1 XA 2 P 2

P0

1 X A

2

2

kCA0 1 X A P

u0 1 X A 2 P0

FA 0

2

dP

T P0

1 XA

dW

2 T0 P P0

1

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

X=0

P0 = 20 atm

PBR, 1000 kg cat

X=?

P = ? atm

2A→B -rA = kCA2

α = 0.0008/kg

k=0.1 dm6/mol∙min∙kg cat at 300 K

FA0 = 10 mol min

4. Combine

5. Relate P/P0 to W

L7b-8

What conversion and P is

measured at the outlet of the

PBR? The rxn is isothermal at 300

K, assume ideal gas behavior, and

the feed contains pure A (g).

dX A kCA0 1 X A P

dW

u0 1 X A 2 P0

dP

P0

1 X A

dW

2 P P0

2

2

Simultaneously solve dXA/dW and dP/dW (or dy/dW) using Polymath

First, need to determine , CA0, & u0.

NTf NT0

1 2

0.5

NT0

2

What is CA0?

P0

20atm

mol

C A0 0.813

CA0

RT0

dm3

dm3 atm

0.082

300K

mol K

FA0

10mol min

dm3

u0

u0 12.3

3

C A0

min

0.813mol dm

P0 V0 NT0RT0

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

X=0

P0 = 20 atm

PBR, 1000 kg cat

X=?

P = ? atm

2A→B -rA = kCA2

α = 0.0008/kg

k=0.1 dm6/mol∙min∙kg cat at 300 K

FA0 = 10 mol min

L7b-10

What conversion and P is

measured at the outlet of the

PBR? The rxn is isothermal at 300

K, assume ideal gas behavior, and

the feed contains pure A (g).

2

dP

P0

dX A kCA0 1 X A P

1 X A

2

dW

2 P P0

dW

u0 1 X A P0

Simultaneously solve dXA/dW and dP/dW (or dy/dW) using Polymath

3

mol

dm

0.5

C A0 0.813

u0 12.3

dm3

min

2

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

X=0

P0 = 20 atm

PBR, 1000 kg cat

X=?

P = ? atm

2A→B -rA = kCA2

α = 0.0008/kg

k=0.1 dm6/mol∙min∙kg cat at 300 K

FA0 = 10 mol min

L7b-11

What conversion and P is

measured at the outlet of the

PBR? The rxn is isothermal at 300

K, assume ideal gas behavior, and

the feed contains pure A (g).

2

dP

P0

dX A kCA0 1 X A P

1 X A

2

dW

2 P P0

dW

u0 1 X A P0

Simultaneously solve dXA/dW and dP/dW (or dy/dW) using Polymath

3

mol

dm

0.5

C A0 0.813

u0 12.3

dm3

min

2

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

What conversion and P is L7b-12

measured at the outlet of the

PBR? The rxn is isothermal at

300 K, assume ideal gas

behavior, and the feed contains

pure A (g).

P = 14.28 atm

X = 0.93

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

What conversion can be achieved in a L7b-13

fluidized CSTR with the same catalyst weight

and P0 = P (ideal gas behavior, pure A feed)?

F X

CSTR design eq: W A0 A

r 'A

FA0 X A

W

kC A0 1 X A

Use info from PBR to determine FA0, CA0 & k

dX A r ' A

dX A kC A

C 1 XA P T0

NT NT0 1 1

0

CA A0

dW

FA0

dW

FA0

NT0

1

1 XA P0 T

Do not plug in P and P0 that occurred in PBR

0

1

yet! Use Ergun eq to get P/P0 as a function of

Use PBR expt

W, plug into design eq & integrate over W!

P

1 W parameters to

Isothermal and =0. Ergun eq for P/P0 becomes:

solve for α

P0

9atm

1 1000kg

20atm

0.2025 1 1000kg

0.0008 kg1

P

0.0008

C

C

1

X

C

C

1

X

1

W

Plug into CA: A

A0

A

A

A0

A

kg

P0

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

L7b-14

What conversion can be achieved in a

fluidized CSTR with the same catalyst weight

and P0 = P (ideal gas behavior, pure A feed)?

F X

CSTR design eq: W A0 A

r 'A

FA0 X A

W

kC A0 1 X A

Use info from PBR to determine FA0, CA0 & k

dX A kC A

0.0008

CA CA0 1 XA 1

W

dW

FA0

kg

0.0008

k CA0 1 X A 1

W Rearrange

kg

dX A

dW

FA0

Plug CA into PBR

design eq:

dX A kC A0

0.0008 Integrate so that we can

W

1 X A 1

dW

FA0

kg get values of unknowns

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

L7b-15

What conversion can be achieved in a

fluidized CSTR with the same catalyst weight

and P0 = P (ideal gas behavior, pure A feed)?

F X

CSTR design eq: W A0 A

r 'A

FA0 X A

W

kC A0 1 X A

dX A kC A 0

0.0008

PBR design eq :

W

1 X A 1

dW

FA0

kg

X A dX

kC A0 W

0.0008

A

W dW

1

FA 0 0

kg

0 1 X A

1000kg

3

0.0008

1 kC A0

2

2

ln

1

1

W

F

3 0.0008 kg

1

X

kg

A

A0

0

1000kg

3

1

1

0.0008

2

kC A 0 2

ln

1

1

W

1

0.141

F

3

0.000

8

kg

kg

A0

0

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

L7b-16

What conversion can be achieved in a

fluidized CSTR with the same catalyst weight

and P0 = P (ideal gas behavior, pure A feed)?

F X

CSTR design eq: W A0 A

r 'A

FA0 X A

W

kC A0 1 X A

dX A kC A 0

0.0008

PBR design eq :

W

1 X A 1

dW

FA0

kg

1000kg

3

1

0.0008

2

1 kC A0 2

ln

1

1

W

kg

0.859 FA0 3 0.0008 kg

0

3

3

kC A 0

2

0.0008

2

0.0008

0.152

833.3 kg 1 1

1000kg 833.3 kg 1 1

0k g

FA0

kg

kg

3

kC A0

kC A0

833.3 kg 1 0.0894

0.152

833.3 kg 1 1 0.8 2 833.3 kg 1 1 0.152 F

FA 0

A0

kC A0

0.152

758.8kg

FA0

2.0 10 4 kg1

kC A0

FA0

Plug this value into

the CSTR eq

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

L7b-17

What conversion can be achieved in a

fluidized CSTR with the same catalyst weight

and P0 = P (ideal gas behavior, pure A feed)?

F X

CSTR design eq: W A0 A

r 'A

FA0 X A

W

kC A 0 1 X A

2.0 10 4 kg1

kC A0

FA0

XA

1000kg

2.0 10 4 kg1 1 X A

1

0.2

XA

0.2 0.2X A X A 0.2 1.2XA 0.17 XA

1 XA

Conversion in fluidized CSTR, no pressure drop

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

A + 2B → C Elementary rxn, feed is a stoichiometric mixture

Fluidized CSTR, isothermal, isobaric, ideal, gas-phase reaction

P0= 6 atm; T = 443K & u0 = 50 dm3/min

k 53

mol

3

kg cat min atm

L7b-18

at 300K with E=80 kJ/mol, elementary rxn

How many kg of catalyst is required to achieve XA = 0.8?

Fluidized

CSTR

design eq:

F X

C u X

W A0 A W A0 0 A

r 'A

r 'A

1. What is CA0?

CA0 y A0CT0

y A0 =

Known: u0 and XA

Unknown: CA0 & -r’A

NA0

NT0

NT0

P

CT0

V

RT

Feed is a stoichiometric mixture

1

1

y A0 =

→ 1 part A, 2 parts B

1 2 3

6atm

P C 1

mol

C A0 y A0

A0

C

0.055

A0

3

3

RT

atm dm3

dm

0.082

443K

mol K

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

L7b-19

A + 2B → C

Elementary rxn, feed is a stoichiometric mixture

Fluidized CSTR, isothermal, isobaric, ideal, gas-phase reaction

P0= 6 atm; T = 443K & u0 = 50 dm3/min

k 53

mol

3

kg cat min atm

at 300K with E=80 kJ/mol, elementary rxn

How many kg of catalyst is required to achieve XA = 0.8?

F X

C u X

W A0 A W A0 0 A

r 'A

r 'A

2. What is –r’A? Units on k are:

r 'A kPA PB2

Ci

Known: u0, XA, & CA0 (0.055 mol/dm3)

Unknown: -r’A

mol

kg cat min atm3

2a. What is PA?

Ni

P

i

V RT

Substitute for Cj & Cj0

Express rate law in terms

of partial pressure, not Cj

C j0 j j X A

For ideal, isobaric,

Cj

isothermal rxn:

1 XA

Pj0

j j XA

Pj

RT

RT

1 XA

Pj0 j j X A

Pj

1 XA

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

L7b-20

A + 2B → C

Elementary rxn, feed is a stoichiometric mixture

Fluidized CSTR, isothermal, isobaric, ideal, gas-phase reaction

P0= 6 atm; T = 443K & u0 = 50 dm3/min

k 53

mol

3

kg cat min atm

at 300K with E=80 kJ/mol, elementary rxn

How many kg of catalyst is required to achieve XA = 0.8?

F X

C u X

W A0 A W A0 0 A

r 'A

r 'A

Known: u0, XA, & CA0 (0.055 mol/dm3)

Unknown: -r’A

2 Units on k necessitate expressing rate law in

2. What is –r’A? r 'A kPAPB

terms of partial pressure, not Cj

2a. What is PA?

A=-1

A=1

PA0 y A0PT0

Pj

Pj0 j j X A

1 XA

NT NT0

y A0

NT0

J

Fj0

FA0

C j0u0

CA0u0

C j0

CA0

1

3

y j0

y A0

y A0 (1 2 1)

1

PA0 6atm PA0 2atm

3

2

3

2atm 1 X A

PA

1 2 3 XA

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

A + 2B → C

Elementary rxn, feed is a stoichiometric mixture

Fluidized CSTR, isothermal, isobaric, ideal, gas-phase reaction

P0= 6 atm; T = 443K & u0 = 50 dm3/min

k 53

mol

3

kg cat min atm

L7b-21

at 300K with E=80 kJ/mol, elementary rxn

How many kg of catalyst is required to achieve XA = 0.8?

F X

C u X

W A0 A W A0 0 A

r 'A

r 'A

2. What is –r’A? r 'A kPAPB

2b. What is PB?

PA0 j j X A

PB

1 XA

2

3

2

Known: u0, XA, & CA0 (0.055 mol/dm3)

Unknown: -r’A

PA

B=-2

PB

2atm 1 X A

1 2 3 XA

B

J

Fj0

FA0

C j0

CA0

FB0 2

2

FA0 1

2atm 2 2X A

4atm 1 X A

PB

1 2 3 XA

1 2 3 XA

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

y j0

y A0

A + 2B → C

Elementary rxn, feed is a stoichiometric mixture

Fluidized CSTR, isothermal, isobaric, ideal, gas-phase reaction

P0= 6 atm; T = 443K & u0 = 50 dm3/min

k 53

mol

3

L7b-22

at 300K with E=80 kJ/mol, elementary rxn

kg cat min atm

How many kg of catalyst is required to achieve XA = 0.8?

FA0 XA

CA0u0 XA

W

W

r 'A

r 'A

2

2. What is –r’A? r 'A kPAPB

2c. What is k at 443K?

k 443K

Known: u0, XA, & CA0 (0.055 mol/dm3)

Unknown: -r’A

PB

4atm 1 X A

1 2 3 XA

k 443K k 300K e

PA

2atm 1 X A

1 2 3 XA

E 1 1

R T1 T2

1

80000J mol 1

8.314J molK 300K 443K

e

mol

53

kgcat min atm3

k 443K 1.663 106

mol

kgcat min atm3

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

A + 2B → C

Elementary rxn, feed is a stoichiometric mixture

Fluidized CSTR, isothermal, isobaric, ideal, gas-phase reaction

P0= 6 atm; T = 443K & u0 = 50 dm3/min

k 53

mol

3

L7b-23

at 300K with E=80 kJ/mol, elementary rxn

kg cat min atm

How many kg of catalyst is required to achieve XA = 0.8?

FA0 XA

CA0u0 XA

W

W

r 'A

r 'A

2

2. What is –r’A? r 'A kPA PB

Known: u0, XA, & CA0 (0.055 mol/dm3)

Unknown: -r’A

4atm 1 X A

1 2 3 XA

mol

6

PB

k 443K 1.663 10

PA

2atm 1 X A

1 2 3 XA

kgcat min atm3

2atm 1 X A 4atm 1 X A

mol

6

r 'A 1.663 10

3 1 2 3 X

1

2

3

X

kgcat

min

at

m

A

A

1 X 3

mol

A

r ' A 1.663 106

32atm3

3

3

1 2 3 X

kgcat min atm

A

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

2

A + 2B → C

Elementary rxn, feed is a stoichiometric mixture

Fluidized CSTR, isothermal, isobaric, ideal, gas-phase reaction

P0= 6 atm; T = 443K & u0 = 50 dm3/min

k 53

mol

3

kg cat min atm

at 300K with E=80 kJ/mol, elementary rxn

How many kg of catalyst is required to achieve XA = 0.8?

C A0u0 X A

CA0 =0.055 mol/dm3

W

r 'A

1 X 3

mol

A

r ' A 1.663 106

32atm3

3

3

1 2 3 X

kgcat min atm

A

mol dm3

50

0.8

0.055

3

mi

n

dm

W

1 0.8 3

mol

6

32atm3

1.663 10

3

3

1 2 3 0.8

kgcat min atm

W 5.24 10 7 kg cat

Copyright © 2014, Prof. M. L. Kraft (mlkraft@illinois.edu). All rights reserved.

L7b-24