Design for Mill/Turning/Drilling

advertisement

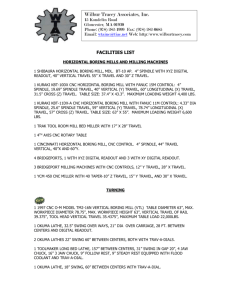

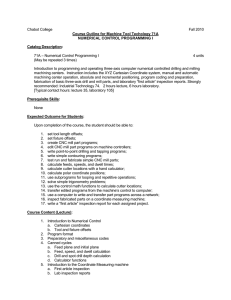

Design for Mill/Turning/Drilling or how to save yourself or your machinist a lot of time and effort Overview • • • • • • Drill Mill Lathe Surface Finish Tips & Tricks Process Planning Drill • Make a hold in something • Drillpress OR hand-held drill • Usually need clamps to hold part in place • Not highly accurate but often good enough A BIG distinction • MANUAL machines vs. CNC machines A BIG distinction • MANUAL machines vs. CNC machines Lathes • Manual • CNC How do choose the correct machine? • Round geometry • Axial alignment • Flat/planar geometry Drill or Mill Lathe • Axial and milled geometry CNC Lathe With live tooling • Odd (not circular) shapes • Pockets, holes, surface geometry CNC Mill Surface Finish Surface Finish From 2.008 class notes, SP03 Surface Finish From 2.008 class notes, SP03 Tips & Tricks For high precision, watch out for • Overhanging geometry (deflection) • Thin sections & tubes (vibration) • Drilling incline planes For ease of manufacturing • • • • • • Standard shape & size holes Proper tolerances (discussed tomorrow) Reference everything off one point Avoid deep pockets & holes NO inside right edges! WATCH OUT for tool access! – a short endmill used inside a deep narrow pocket might CRASH!) – Don’t cut into the vise or clamps! Mill: Part in Vise To make it faster (& less annoying) • Minimize number of fixtures – Every time you take the part out of the vise you have to re-reference it – wastes time! • Include features for easy fixturing & referencing Image from: http://www.wmccm.co.uk/WMCCM/DesktopDefault.aspx?tabindex=0&tabid=2049 Process Planning Process Planning From 2.008 Process Planning lecture, SP03 Process Planning TOMORROW Look for departmental resources Machine shop resources Buy material Make material correct size From 2.008 Process Planning lecture, SP03 Detailed Process Planning for Manufacturing • Choose material and order it • Make material correct starting size/shape – Watch for tolerances when ordering – parts aren’t always exact size or perfectly square • Plan what cuts/features to make first, second, third based on complexity, yield of process, etc. - SKETCH – If something is likely to not work, don’t do that step last! Detailed Process Planning for Manufacturing, Continued… • Determine when to check for quality/accuracy in the process – Easier to measure twice and cut once than the other way around! • For any hand-machining operations, mark the parts in an OBVIOUS way! – ei, an X on the part that you don’t want, scribble where you want material removed Optimizing your Process Plan • Fewer steps = better • Make a flowchart How Its Made Examples Resources • • • • Machinery’s Handbook Manufacturing textbooks (Kalpakjian) Your local machinist MIT shops – MIT departmental shops – Edgerton Student Shop (on Vassar Street) – MIT Hobby Shop