our Facilities List in Microsoft Word Format

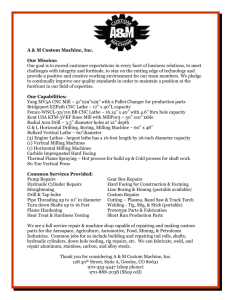

advertisement

Wilbur Tracey Associates, Inc. 15 Kondelin Road Gloucester, MA 01930 Phone: (978) 282-1999 Fax: (978) 282-0685 Email: wtainc@tiac.net Web: http://www.wilburtracey.com FACILITIES LIST HORIZONTAL BORING MILLS AND MILLING MACHINES 1 SHIBAURA HORIZONTAL BORING MILL, MDL. BT-10 AP. 4” SPINDLE WITH XYZ DIGITAL READOUT, 40” VERTICAL TRAVEL 55” X TRAVEL AND 30” Z TRAVEL. 1 KURAKI KBT-10DX CNC HORIZONTAL BORING MILL WITH FANUC 15M CONTROL: 4” SPINDLE, 19.69” SPINDLE TRAVEL, 40” VERTICAL (Y) TRAVEL, 60” LONGITUDINAL (X) TRAVEL, 31.5” CROSS (Z) TRAVEL. TABLE SIZE: 37.4” X 43.3”. MAXIMUM LOADING WEIGHT 4,400 LBS. 1 KURAKI KBT-11DX-A CNC HORIZONTAL BORING MILL WITH FANUC 11M CONTROL: 4.33” DIA SPINDLE, 25.6” SPINDLE TRAVEL, 59” VERTICAL (Y) TRAVEL, 78.74” LONGITUDINAL (X) TRAVEL, 57” CROSS (Z) TRAVEL. TABLE SIZE: 63” X 55”. MAXIMUM LOADING WEIGHT 6,600 LBS. 1 TRAK TOOL ROOM MILL BED MILLER WITH 17” X 28” TRAVEL 1 4TH AXIS CNC ROTARY TABLE 1 CINCINNATI HORIZONTAL BORING MILL, CNC CONTROL. 4” SPINDLE, 44” TRAVEL VERTICAL, 40”X AND 60”Y. 4 BRIDGEPORTS, 1 WITH XYZ DIGITAL READOUT AND 3 WITH XY DIGITAL READOUT. 3 BRIDGEPORT MILLING MACHINES WITH CNC CONTROLS, 12” Y TRAVEL, 28” X TRAVEL. 1 YCM 450 CNC MILLER WITH 40 TAPER-10” Z TRAVEL, 15” Y TRAVEL, AND 30” X TRAVEL. TURNING 1 1997 CNC O-M MODEL TM2-16N VERTICAL BORING MILL (VTL) TABLE DIAMETER 63”, MAX. WORKPIECE DIAMETER 78.75”, MAX. WORKPIECE HEIGHT 63”, VERTICAL TRAVEL OF RAIL 39.375”, TOOL HEAD VERTICAL TRAVEL 35.4375”, MAXIMUM TABLE LOAD 22,000LBS. 1 OKUMA LATHE, 32.5” SWING OVER WAYS, 21” DIA OVER CARRIAGE, 28 FT. BETWEEN CENTERS AND DIGITAL READOUT. 2 OKUMA LATHES 22” SWING 60” BETWEEN CENTERS, BOTH WITH TRAV-A-DIALS. 1 TOOLMAKER LONG BED LATHE, 157” BETWEEN CENTERS, 31” SWING IN GAP 20”, 4 JAW CHUCK, 16” 3 JAW CHUCK, 9” FOLLOW REST, 9” STEADY REST EQUIPPED WITH FLOOD COOLANT AND TRAV-A-DIAL. 1 OKUMA LATHE, 18” SWING, 60” BETWEEN CENTERS WITH TRAV-A-DIAL. FACILITIES LIST PAGE 2 1 SHELDON TURRET LATHE, 14” SWING, 6 TOOL STATIONS. 1 BULLARD 54” VERTICAL TURRET LATHE WITH DIGITAL READ OUT. 1 MEUSER LATHE, 42” CHUCK, 72” FACE PLATE, 60” BETWEEN CENTERS. 1 MEUSER LATHE WITH 40” SWING, 120” BETWEEN CENTERS. 1 MIMIC 9000 HYDRAULIC TRACER, FITS ALL OUR LATHES. 1 SLANT 50 CNC TAPE LATHE, CHUCK CAPACITY OF 12.5” DIAMETER, 26” BETWEEN CENTERS. 1 TAKISAWA CNC TS25 LATHE, CHUCK CAPACITY OF 12”, 38” BETWEEN CENTERS. DRILLING 1 THREE HEAD GANG DRILL WITH 60” TABLE. 1 CLAUSING DRILL WITH TAPPING HEAD. 1 SQUARE TAPPING MACHINE WITH ALL AVAILABLE ATTACHMENTS. CUTTING 1 HORIZONTAL BAND SAW. 1 VERTICAL BAND SAW. 1 COLD SAW WITH 12 FT. TABLE FOR CUTTING TUBING. FINISHING 1 LARGE TUMBLER. 1 8” UPRIGHT BELT SANDER. 1 DUMORE TOOL POST GRINDER. 2 OVERHEAD CRANES, 1 5TON, 1 10TON CAPACITY. 1 60” TIME SAVER. 4 COMPUTERS FOR JOB TRACKING. 3 TRUCKS- ONE ¾ TON, AND TWO 2TON. 2000 SQUARE FOOT FAB SHOP. FULL WELDING FACILITIES (MILLER MIG WELDER AND MILLER SYNCHROWAVE 350 TIG WELDER).