Microbial Enhanced Oil Recovery-Laboratory Experiments with a

advertisement

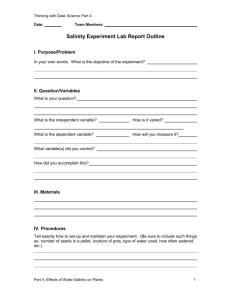

I.A Jimoh, Rudyk S.N and Søgaard E.G Section of Chemical Engineering, Department of Chemistry, Biotechnology and Chemical Engineering, Aalborg University, Campus Esbjerg Denmark • Introduction •Enhanced Oil Recovery Methods and why are they needed? • Microbial Enhanced Oil Recovery • Experimental Study (Objectives) • Results of Laboratory Investigations • Conclusions/Further Works 2 • Currently global energy production from fossil fuels is about 80-90% with oil and gas representing about 60 % • During oil production, primary oil recovery can account for between 30-40 % oil productions • While additional 15-25% can be recovered by secondary methods such as water injection leaving behind about 3555 % of oil as residual oil in the reservoirs • This residual oil is usually the target of many enhanced oil recovery technologies and it amounts to about 2-4 trillion barrels (Hall et al., 2003) www.energyinsights.net 3 Enhanced oil recovery (EOR) methods aimed to recover additional oil after primary recovery or natural drives in the reservoirs •Water flooding (water injection) •Gas injection (not miscible) •Carbon dioxide flooding (miscible) •Steam injection and in-situ burning •Surfacants or foams injection •Microbial Enhanced Oil Recovery Methods 4 Use of microbes to improve oil recovery, established by Beckman 1926 How much additional oil can be produced? Up to 60% oil in place after primary recovery 5 6 Bioproduct Acids Effect Modification of reservoir rock Improvement of porosity and permeability Biomass Reaction with calcareous rocks and CO2 production Selective or non selective plugging Emulsification through adherence to hydrocarbons Modification of solid surfaces Degradation and alteration of oil Reduction of viscosity and oil pour point Desulfurization of oil Gases (CO2, CH4, H2) Reservoir repressurization Oil swelling Viscosity reduction Increase permeability due to solubilization of carbonate rocks by CO2 Solvents Dissolving of oil Lowering of interfacial tension Surface-active agents Emulsification Polymers Mobility control Selective and non-selective plugging After Janshekar, 1985 7 Microbial Enhanced Oil Recovery (MEOR) is a technology using micro-organisms to facilitate, increase or extend oil production from reservoir. Average size of microbe is one micron, 10,000th of cm. More than 27,000 species of bacteria have been identified. The bacteria, which can be mobile or non-mobile, have three basic shapes: round (coccus), rod (bacillus) and spiral (spirillum). Microbes are the most primitive earth's single celled organisms. Their basic role in life is to recycle the components of living organisms, converting them to the nutrient chemicals used by plants in photosynthesis & chemosynthesis. Shape of Microbes During last 15 years some countries began to develop and apply MEOR methods successfully again such as USA, Russia, Romania, Germany, Malaysia, China, India, Norway, UK, Venezuela, Iran, Trinidad among others. More than 300 cases of MEOR methods application – mostly of single well stimulation – were reported. 1. 2. 3. Selective Plugging Hydrocarbon Chain Degrading Bacteria Cyclic Microbial Recovery Znamenskiy Field, Russia: • Microbes of activated sludge and bio-stimulators application on the last stage of carbonate rock field development. • Totally during 1996-2002, 68 injectors were treated. • 1 t of bio-product gave up to 756 t of oil. Microbes plug the washed out tunnel forcing water to flow through yet unwashed areas. Stimulating naturally occurring bacteria that feed on oil to create conditions that release residual oil from the reservoir. The interfacial tension between water and oil is lowered resulting in easier oil recovery. Statoil Applying an aerobic MEOR technique to the development of Norne field. Considers that the technique will produce about 32 million incremental barrels; about 6% above what would otherwise have been recovered. Carbon hungry bacteria are injected by Statoil into the Norne field to free oil clinging to the reservoir rock and enhanced recovery A large group of bacteria is able to cut hydrocarbon chains thus decreasing the viscosity of oil. The microbes degrade hydrocarbons to the following components Heavy oil field in Western Siberia, Russia, January, 2006 Before Treatment After Treatment For a Period 3 Months Production rate 5 - 7 m3/h 15 -19 m3/h (mostly 1617 m3/h) Water cut 48 % 25 % Quality of oil - improved Viscous Oil (Bokor Field Malaysia) Before Treatment After Treatment Over past 5 months (post MEOR) Production rate 152 b/d 334 b/d Water cut 75 % 45 % Lazar et al., 2007:Microbial Enhanced Oil Recovery Microbes replicate -process is self sustaining Eliminates logistical hassle Self- directing Find their own carbon source in the reservoir Create recovery enhancing chemicals where needed A Rather cheap method compared to CO2 injection Selfpropagating 15 High salinity High temperature High pressure in oil reservoirs pH Pore geometry The big question is how to find the right candidate! 16 1). Can the selected bacterium Cloostridium Tyrobutyricum produce desired metabolites needed for enhanced oil recovery? 2). Can the selected bacterium Clostridium Tyrobutyricum survive at high salinities and Self- directing perform its metabolism to a certain extent? 3). How will pH, gas production and acid production change as a function increasing salinity? What about the creation of biopolymers? 4). What is the influence of chalk exposed for microbial metabolism? 5). Can we have improved recovery from residual oil using this strain ? All experiments are performed at temperature 37 oC and ambient pressure 17 Self- directing Salinity effect on bacteria morphology : Note the round shaped bacteria 18 Cummulative gas vol (ml) 4000 Pure culture 3000 Adapted strain 2000 1000 0 10 30 50 90 100 Salinity (g/l) Component Carbon dioxide Hydrogen Nitrogen Total % Composition 83.66 16.23 0.11 100.0 Cumulative gas production at different salinity and gas composition 19 24 Hours Rs mol/litre/hour 0.0003 72 Hours 120 Hours 0.00015 0 0 20 40 60 80 100 Salinity (g/l) Rate of absorption of CO2 in the fermentation media 20 2500 n-butyric acid (mg/L) 2000 40 g/L 1500 50 g/L 60 g/L 70 g/L 1000 80 g/L 90 g/L 500 100 g/L 0 0 40 80 120 Time (Hours) Acid production at different salinity with Clostridium tyrobactericum 21 2500 n-butyric acid ( mg/L) 2000 1500 24 HOURS 72 HOURS 1000 120 HOURS 500 0 4 4.5 5 5.5 6 6.5 7 pH Acid production and pH variation at different salinity 22 Pre-treat porosity 60 Post-treat porosity Porosity (%) 55 50 45 40 35 30 1 1 2 2 3 3 4 4 5 5 6 6 7 7 Time (weeks) Porosity modification of 14 chalk samples immersed in bacteria media 23 Carbonate rock matrix in microbial media 24 Biofilm thickness (cm) 1 0.8 0.6 0.4 0.2 0 0 30 60 90 120 150 Salinity (g/L) 10 days 20 days 30 days 40 days Biofilm formation at oil water interface 25 Parameters Value Initial Oil Saturation 120 ml Residual Oil Saturation after Water Flooding 33 ml Nutrient Injected 0.4 PV Inoculums 0.2 PV Incubation 37 oC for 7 Days Secondary Water Flooding 7 PV Oil Displaced after Secondary Water Flooding 13 ml % Oil Recovery after Microbial Treatment 39% (I PV=170ml) Oil recovery from packed sandstone column 26 1). The selected bacterium (Clostridium tyrobuyticum) can produced desired metabolites needed for residual oil recovery thus eliminating use of harsh chemicals. 2). The microbes can survive and become adapted to conditions with high salinities. however, their metabolism is decreasing with increasing salinity. 3). Gas production shows a mixture of CO2 and H2 which amounts are decreasing with increasing salinities. Biofilms are createdup to 100 g/L of salinity. 4). The porosity of chalk increases as a function of time probably because of the acidic dissolution of the chalk. 5). Residual oil recovery greater than 30% was achieved. 27 Thank you for your attention! Contact Address: Room B115, Niels Bohrs Vej 8 Esbjerg, DK 6700, Denmark iaj@bio.aau.dk 28