Final Presentation

advertisement

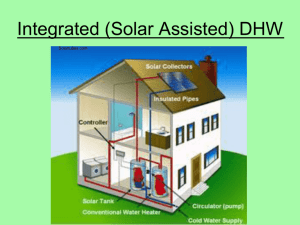

Performance Modeling of Low Cost Solar Collectors in Central Asia Project Presentation Steph Angione, Zach Auger, Adrienne Buell, Suza Gilbert, Emily Kunen, Missy Loureiro, Alex Surasky-Ysasi, Amalia Telbis Problem Definition • Goal: Design a performance model for a solar collector in central Asia • Specifications: – Heat water for domestic use – Be low cost – Use local materials – Be efficient – Be easily maintained – Be sustainable Step 1:Background Research • Background Research: – Region and climate data – Materials and availability – Heat transfer – Testing and modeling process Geography, Climate and Housing: Tajikistan – Latitude of 34°00’N and longitude of 68°00’E – More than half of the country lies above 3,000 meters – Climate • Highlands similar to lower Himalayas – Housing • Built into the mountains • Multifamily/ multistory – Construction • Raw bricks, plaster & cut straw (horizontal layers) • Where available: wood used for roof beams • Cement often used for roof Geography, Climate and Housing : Afghanistan – Latitude of 33°00’N and longitude of 65°00’E – Includes three distinct areas: • central highlands, southern plateau, and northern plains – Climate • hottest in southwest, coldest in northern regions with waves of intense cold and temperatures below zero – Housing • Construction Materials: stone, coniferous wood, plaster, straw, and brick • Terraced Housing Materials • What to look for when choosing a material: – – – – – – Thermal Properties Durability Availability Construction Methods Maintenance Costs • Materials Specified by EWB: – – – – – Sheet Metal Wood Glass Black Paint Horsehair • Regional Materials: – Clay, Cement, Brick, Sheep Wool, Straw, Plaster Sheet Metal • Variety of metals available – Best heat capacity – Aluminum [903 J/kg*K] – Best conductivity – Copper [401 W/m*K] • Durability and Construction Methods: – Cutting tasks only require aviation snips – Pieces are easy to bend Copper Sheet: • Can be shaped into any form easily • Doesn’t not crack when hammered, stamped, forged or pressed • Resists corrosion and does not rust • Can be recycled • Easiest metal to solder Aluminum Sheet: • Excellent conductor of heat • Light (about 1/3 weight of copper) • Withstands wind, rain, chemicals, pollution • Excellent durability • Can be recycled • Soldering requires specialized reaction fluxes and tools • Wood: – Used for construction • Easily cut – Hand-tools sufficient – Durable insulation – Readily available • Black Paint: – Used to absorb solar energy by changing the absoptivity • Absorptivity = a = 94% – Radiates back 90% of solar radiation • Horsehair and sheep wool: – Used for insulation: lasts for over 200 years – Material readily available • 0.3 million horses in Afghanistan • 11-14 million sheep in Afghanistan • Glass: – Used as glazing – Reduces losses – Has to be tempered and have high transmittance • Other insulation: – Bousillages – mixture of moss and clay • Outer layer is a mixture of horsehair, water, and clay Heat Transfer Formulas • Conduction – Fourier’s Law: dQ/dt=-kA(dT/dx) – Through a material • Convection – Newton’s Law of Cooling: dQ/dt=hA(Ts-Tf) – Fluid flowing past a solid • Radiation – Stephan-Boltzman Law: dQ/dt=εσATb4 – Heat emitted by an object Hot Material Components of a Solar Collector • Absorber Plate • Absorber Surface Coatings • Glazing • Insulation • Casing Testing and Modeling •Determine All Variables and Constants • Visualized Design/Schematic –CAD software: •SolidWorks, ProE –Free-hand sketches Calculations • Use of MatLab or Excel • Use of possible simulations – F-chart! – TRNSYS Step 2: Identify the Situation • Specified Situation: – Domestic hot water heating for average household size of 7 people – Water use per person per day: 25 liters – Region: rural, mountainous – System output temperature: 60 °C – Year round functionality – Storage tank water capacity: 1-2 days – Delivery system: either batch or continuous flow Step 3: Selected Designs To Model Solar Heater Types and Designs • Passive vs. Active Solar Heaters – Active • use pumps to circulate water or an antifreeze solution through heatabsorbing solar thermal collectors 1.1 Open Loop Direct Water Heating Use Pump – Passive • The water is circulated without the aid of pumps or controls • Open Loop vs. Closed Loop • If the liquid that needs to be heated is also the one being circulated: Open Loop • If antifreeze or another solution used in a heat exchanger to heat the water: Drain-Back Freeze Protection Cost Less More Efficient UNRELIABLE 1.2 Closed Loop Drain Down One Liquid Unreliable Freeze Protection Drain Back 2 Liquids Heat Exchanger Closed Loop Antifreeze Solution Less Efficient Good Freeze Protection • Possibilities and their +/…what we ended up picking Active – Open Loop: • (+) cost less • (-) pump controlled • (-) only possibility for freeze protection: manually draining X Second one OUT !!! – Closed Loop: • Drain Down: – (-): not reliable !!! X First one OUT !!! • Drain Back: – (+) good freeze protection – (+) can use water/water instead of antifreeze – (-) pump and 2 different storage tanks • Passive – Batch • (+)easy (can even be a tank painted in black) • (+) offers freeze protection because the water is only present in the tanks and the areas are large; the water cools off slowly • (-) takes long to heat the amount of water – Thermosyphon • • • • • (+) no need for pumps (+) offers good freeze protection (-) heavy tank placed above the collector (-) efficiency decreases when using indirect heating We voted between: Drain Back, Batch and Thermosyphon – Systems chosen • Group I (Suza, Missy, Emily and Zach): Drain • Back System Group II (Stephanie, Adrienne, Alex and Amalia): Thermosyphon Team Drain Back Team Members: •Melissa Loureiro •Emily Kunen •Suza Gilbert •Zach Auger Drainback • • • • • • • • Solar collector located above storage tank 2 liquid system • Both can be water • 1liquid water and 1an antifreeze solution Active closed loop system • Uses pump Pump circulates water through collectors when collectors are warmer than stored water Heat exchanger used in storage tank Heat transfer between circulating fluid and potable water Circulating solution drains to a 2nd tank when pump shuts off Tank is placed on a tilt for complete drainage Team Drain Back System • Collector – – – – – – 28 parallel copper pipes Copper plate 1.13m^2 area Soda lime glass glazing Sheep wool insulation Black interior • Housing • Heat Exchanger – Heat transfer fluid flows through exchanger – Exchanger within storage tank containing working fluid • Pump • Drain back Reservoir Model •Software: Microsoft Excel •Spreadsheets for: -Materials -Energy Input and Output -Collector -Heat Exchanger -Sunlight -Efficiency Efficiency and Costs – Soft Copper Tubing for Heat Exchanger: $83.26/100 feet – Copper Sheet: $147.30/ 2 sheets – Copper Feeder Pipes: $26.00/12 feet – Glazing: $320.00/ 2 sheets – Black Paint: $30/gallon •Efficiency: Efficiency 90.00% 89.80% 89.60% 89.40% Efficiency • Total Cost: US$1167.02 89.20% 89.00% Sheep wool Bousillage Clay 88.80% Straw 88.60% 88.40% Jan Feb March Apr May June Month July Aug Sept Oct Nov Dec What’s Next • Performance Modeling – Several days of testing – Slight variations in model • Prototype – Improve construction techniques – Compare to performance model Team Thermosyphon Amalia Telbis Alex SuraskyYsasi Steph Angione Adrienne Buell Thermosyphon – – – – Area 1.85 m^2: standardized according to available glazing Absorber Plate: 0.02” thick copper sheet bent around the parallel pipes Glazing: 1/8” thick single glass sheet with 0.01% iron-content Parallel Flow Pattern: Copper piping • Header and footer 1.5” • Parallel pipes 0.5” • Free floating array supported by wood risers every 10” – Housing: Wood frame that slides into the mounting stand at 33o – Insulation: • dead air between plate and layer of plywood • boussilage clay, water, and horsehair • 1m high stand with brick walls encasing dead air – Back flow prevention: one way valve – Pressure relief valve needed at high antifreeze temperatures Thermosyphon: • Working fluid: 40.5% ethanol-water mixture • Boiling Temperatures: 84oC • Freezing Temperature: -24oC • Heat exchanger: • Countercurrent • Bendable copper tubing: 1”outer diameter – Length: 9m – 11 loops- 0.25m diameter spaced at 1.05” • Storage tank: placed above the solar collector • Dimensions: 0.5m x 0.5m x 1.05 m steel casing • Insulation: sheep wool, boussilage and brick Modeling: • Software used: Excel • Governing Equations: • Efficiency (%) 92 1/5inch pipe 90 3/4inch pipe 88 86 84 82 80 78 0 10 20 30 40 50 60 70 Mixt Tem p (oC) Temp of Plate vs Temp of Mixture 160 140 120 Temp Plate (oC) • – Heat transfer in the solar collector – Mass flow rate calculation – Heat transfer in the heat exchanger Collector plate efficiencies at a constant ambient temperature (20oC) for parallel pipes of different sizes vs. the temperature of the antifreeze Collector plate temperatures at a constant ambient temperature (20°C) for parallel pipes of different sizes vs. the temperature of the antifreeze Efficiency vs Mixt Tem perature 94 100 80 1/5inch pipe 60 3/4 inch pipe 40 20 0 0 10 20 30 40 Temp Mixt (oC) 50 60 70 Results: Annual Output Temperatures of both the water and the antifreeze: The water reaches The antifreeze reaches ▪ app. 30°C in the winter ▪ app. 58°C in the summer ▪app. 65°C in the winter ▪above boiling point in summer Antifreeze End Temperature in Kabul Performance in Kabul AnnualDaily Performance in Kabul 100 100 100 90 90 90 Temperature at Start of Hour (C) 70 70 70 60 60 50 50 60 50 40 40 40 3030 30 December Antifreeze 2020 December Water 20 June Antifreeze 1010 June Water 10 2 Ju ly Ju ly Ju n Ju e ne M a My ay Ap April ril 4 6 Au gu Au s t gu st Se pt Se em pt ber em be r O ct ob O er ct ob er No ve m No be ve r m be De r ce m De be ce r m be r 0 M a M rch ar ch 0 Fe Febr u br ar ua y ry 00 Ja Janu nua ry ar y Output Temperature of Water (C) Temperature (C) 80 80 80 8 Hour Month Month 10 12 14 What’s next? • • • • • Use computer programming software – F-chart method to analyze efficiencies – Matlab to ease the process of iteration Optimize design Model different regions Change the working fluid during the summer or use a different antifreeze solution Make a business plan and try to implement Design Comparison DRAIN BACK THERMOSYPHON Freeze protection = draining system Freeze protection =working fluid: ethanol-water mixture Powered by pump Uses natural convection Price ~ $1167 US Collector Area = 1.13 meters^2 Parallel pipes in collector = 28 Parallel pipe outer diameter = .625 in Single Glazing Length of Heat Exchanger = 3.01 meters Price ~ $1250 US Collector Area = 1.85 meters^2 Parallel pipes in collector = 21 Parallel pipe outer diameter = .5 in Single Glazing Length of Heat Exchanger = 9 meters Implementation: The need for sustainable development What is Sustainable Development? • Meeting present needs with out compromising those of the future • Goals – Improve quality of life – Promote further economic growth – Improve social conditions and equality – Protect and improve environmental and human health How can our project be made sustainable? • Use local resources, knowledge, and skills • Include local involvement in – Planning – Design – Implementation • Have education and training to foster an understanding of and appreciation for the technology • Develop renewable energy markets to encourage further research and economic growth, making the technology competitive and desirable What Comes Next If only we had more time… Designing -Solar collector designs limited to those in existence that have been tested -Overlooked Possibilities -Collector plate designs -Materials Modeling -Optimizing values of the collector using computer programs -Designing a program where a user enters desired parameters and the output is their personalized collector Prototyping and Testing -Theoretical model vs. Prototype -Need to construct and TEST a real model -Compare theoretical and experimental values -Construction techniques can be simplified ACKNOWLEDGEMENTS • • • • • • • Dr. Chris Bull Peter Argo – US Embassy in Tajikistan Professor Chason Professor Hurt Professor Tripathi Professor Breuer EWB!