Class-6b

advertisement

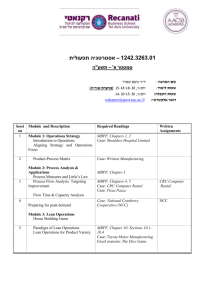

Operations Management & Performance Modeling

1

2

3

4

Operations Strategy

Process Analysis

Lean Operations

Supply Chain Management

5 Capacity Management in Services

– Class 6b: Capacity Analysis and Queuing

» Why do queues build up?

» Performance measures for queuing systems

» The need for safety capacity

» Throughput of queuing system with finite buffer

» Pooling of capacity

6 Total Quality Management

7 Business Process Reengineering

OM&PM/Class 6b

1

Telemarketing at L.L.Bean

During some half hours, 80% of calls dialed received a busy

signal.

Customers getting through had to wait on average 10 minutes

for an available agent. Extra telephone expense per day for

waiting was $25,000.

For calls abandoned because of long delays, L.L.Bean still paid

for the queue time connect charges.

In 1988, L.L.Bean conservatively estimated that it lost $10

million of profit because of sub-optimal allocation of

telemarketing resources.

OM&PM/Class 6b

5

Telemarketing: deterministic analysis

30%

30%

20%

20%

10%

10%

0%

0%

195

40%

180

50%

40%

165

50%

150

60%

135

60%

120

70%

105

80%

70%

90

80%

75

90%

60

90%

45

Flow Time = 8 min

100%

0

100%

30

– one customer every 10

minutes

Flow Time Distribution

15

it takes 8 minutes to

serve a customer

6 customers call per

hour

Probability

Flow Time (minutes)

OM&PM/Class 6b

6

Telemarketing with variability in

arrival times + activity times

80%

15%

60%

10%

40%

5%

20%

0%

0%

– exhibit variability

190

More

180

170

160

150

140

130

120

110

90

100

80

70

60

50

40

30

Flow Time

In reality arrival times

30%

100%

90%

25%

Probability

20

0

– exhibit variability

20%

10

In reality service times

100%

90%

Probability

25%

80%

70%

20%

60%

15%

50%

40%

10%

30%

20%

5%

10%

OM&PM/Class 6b

190

180

170

160

150

More

Flow Time

140

130

120

110

90

100

80

70

60

50

40

30

20

0

0%

10

0%

7

Telemarketing with variability:

The effect of utilization

Average service time =

– 9 minutes

100%

7%

90%

80%

Probability

8%

6%

70%

5%

60%

4%

50%

3%

40%

30%

2%

20%

More

190

180

170

160

150

Flow Time

140

130

120

110

90

100

80

70

60

50

40

30

20

0%

10

10%

0%

0

1%

25%

100%

90%

Average service time =

– 9.5 minutes

Probability

20%

80%

70%

15%

60%

50%

10%

40%

30%

5%

20%

10%

190

180

170

160

150

More

Flow Time

OM&PM/Class 6b

140

130

120

110

100

90

80

70

60

50

40

30

20

0%

10

0

0%

8

Why do queues form?

utilization:

– throughput/capacity

variability:

– arrival times

– service times

– processor availability

Call #

10

9

8

7

6

5

4

3

2

1

0

0

20

40

60

80

100

TIME

Inventory (# of calls in system)

5

4

3

2

1

0

OM&PM/Class 6b

0

20

40

60

TIME

80

100

9

Cycle Times in White Collar Processes

Industry

Process

Average

Cycle Time

Theoretical

Cycle Time

Process Efficiency

Life Insurance

New Policy

Application

72 hrs.

7 min.

0.16%

Consumer

Packaging

New

Graphic

Design

Consumer

Loan

18 days

2 hrs.

0.14%

24 hrs.

34 min.

2.36%

Hospital

Patient

Billing

10 days

3 hrs.

3.75%

Automobile

Manufacture

Financial

Closing

11 days

5 hrs

5.60%

Commercial

Bank

OM&PM/Class 6b

10

Queuing Systems to model Service

Processes: A Simple Process

Order Queue

“buffer” size K

Sales Reps

processing

calls

Incoming calls

Calls

on Hold

Answered Calls

MBPF Inc. Call Center

Blocked Calls Abandoned Calls

(Busy signal) (Tired of waiting)

OM&PM/Class 6b

11

What to manage in such a process?

Inputs

– InterArrival times/distribution

– Service times/distribution

System structure

– Number of servers

– Number of queues

– Maximum queue length/buffer size

Operating control policies

– Queue discipline, priorities

OM&PM/Class 6b

12

Performance Measures

Sales

– Throughput R

– Abandonment

Cost

– Server utilization r

– Inventory/WIP : # in queue/system

Customer service

– Waiting/Flow Time: time spent in queue/system

– Probability of blocking

OM&PM/Class 6b

13

Queuing Theory:

Variability + Utilization = Waiting

Throughput-Delay curve:

Actual

Average

Cycle

Time, W

Variability

Theoretical

Cycle Time

m

Pollaczek-Khinchine Form:

100%

Utilization r

– Prob{waiting time in queue < t } = 1 - exp(-t / Ti ) where:

1

r

Ti

Rp 1 r

OM&PM/Class 6b

Ci2 C p2

2

mean service utilization variability

x

x

time

effect

effect

14

Levers to reduce waiting and increase QoS:

variability reduction + safety capacity

How

reduce system variability?

Safety Capacity = capacity carried in excess of

expected demand to cover for system variability

– it provides a safety net against higher than expected arrivals

or services and reduces waiting time

OM&PM/Class 6b

15

Example 1: MBPF Calling Center

one server, unlimited buffer

Consider MBPF Inc. that has a customer service representative

(CSR) taking calls. When the CSR is busy, the caller is put on

hold. The calls are taken in the order received.

Assume that calls arrive exponentially at the rate of one every

3 minutes. The CSR takes on average 2.5 minutes to complete

the reservation. The time for service is also assumed to be

exponentially distributed.

The CSR is paid $20 per hour. It has been estimated that each

minute that a customer spends in queue costs MBPF $2 due to

customer dissatisfaction and loss of future business.

– MBPF’s waiting cost =

OM&PM/Class 6b

16

Example 2: MBPF Calling Center

limited buffer size

In reality only a limited number of people can be put on hold

(this depends on the phone system in place) after which a

caller receives busy signal. Assume that at most 5 people can

be put on hold. Any caller receiving a busy signal simply calls

a competitor resulting in a loss of $100 in revenue.

– # of servers c = 1

– buffer size K = 6

What is the hourly loss because of callers not being able to get

through?

OM&PM/Class 6b

17

Example 3: MBPF Calling Center

Resource Pooling

2 phone numbers

– MBPF hires a second CSR who is

assigned a new telephone number.

Customers are now free to call

either of the two numbers. Once

they are put on hold customers

tend to stay on line since the other

may be worse ($111.52)

50%

Queue Server

50%

Queue Server

1 phone number: pooling

– both CSRs share the same

telephone number and the

customers on hold are in a single

queue ($61.2)

Queue

Servers

OM&PM/Class 6b

18

Example 4: MBPF Calling Center

Staffing

Assume

that the MBPF call center has a total of 6

lines. With all other data as in Example 2, what is the

optimal number of CSRs that MBPF should staff the

call center with?

– c=3

OM&PM/Class 6b

19

Class 6b Learning objectives

Queues build up due to variability.

Reducing variability improves performance.

If service cannot be provided from stock, safety capacity must

be provided to cover for variability.

Tradeoff is between cost of waiting, lost sales, and cost of

capacity.

Pooling servers improves performance.

OM&PM/Class 6b

20

National Cranberry Cooperative

Hourly Berry Arrivals

2500

2298

2000

1792

1713

1680

1477

1335

1395

1500

1269

1341

1317

Bbls

1032

1016

1000

539

500

0

0

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Time

OM&PM/Class 6b

21

Real Processes exhibit variability in

order placement time and type

National Cranberry on Sept 23, 1970

Histogram of Truck Weights

40

40

35

35

Frequency (# of trucks)

Frequency (# of trucks)

Histogram of Truck inter-delivery times

30

25

20

15

10

5

30

25

20

15

10

5

0

0

0

2

4

6

8

10

12

14

16

Truck interarrival time (min)

OM&PM/Class 6b

18

20

0

4

8

12

16

20

24

28

32

36

40

Truck Weight (Kpounds)

22