PowerPoint Presentation - Gajendra Pratap Singh

advertisement

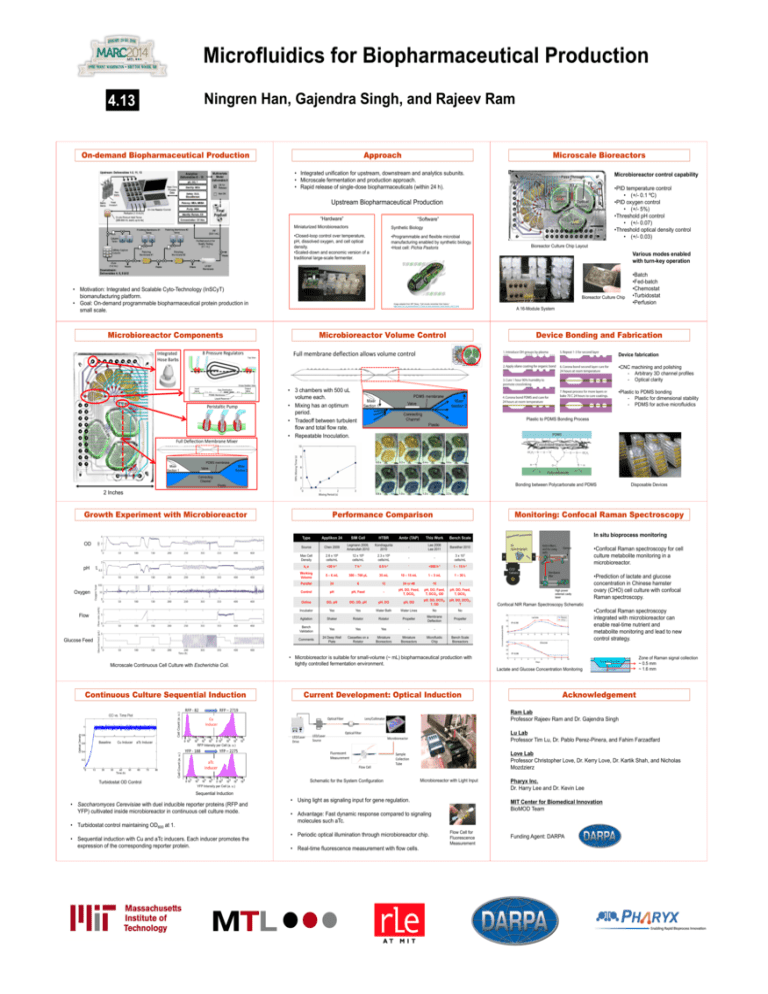

Microfluidics for Biopharmaceutical Production Ningren Han, Gajendra Singh, and Rajeev Ram 4.13 On-demand Biopharmaceutical Production Approach Microscale Bioreactors • Integrated unification for upstream, downstream and analytics subunits. • Microscale fermentation and production approach. • Rapid release of single-dose biopharmaceuticals (within 24 h). Microbioreactor control capability •PID temperature control • (+/- 0.1 ºC) •PID oxygen control • (+/- 5%) •Threshold pH control • (+/- 0.07) •Threshold optical density control • (+/- 0.03) Upstream Biopharmaceutical Production “Hardware” “Software” Miniaturized Microbioreactors Synthetic Biology •Closed-loop control over temperature, pH, dissolved oxygen, and cell optical density. •Scaled-down and economic version of a traditional large-scale fermenter. •Programmable and flexible microbial manufacturing enabled by synthetic biology. •Host cell: Pichia Pastoris Various modes enabled with turn-key operation • Motivation: Integrated and Scalable Cyto-Technology (InSCyT) biomanufacturing platform. • Goal: On-demand programmable biopharmaceutical protein production in small scale. Bioreactor Culture Chip Image adapted from MIT News, “Cell circuits remember their history,” http://web.mit.edu/newsoffice/2013/cell-circuits-remember-their-history-0210.html Microbioreactor Components Integrated Hose Barbs 8 Pressure Regulators Bioreactor Culture Chip Layout A 16-Module System Microbioreactor Volume Control Device Bonding and Fabrication Full membrane deflection allows volume control Device fabrication •CNC machining and polishing - Arbitrary 3D channel profiles - Optical clarity C Peristaltic Pump •Batch •Fed-batch •Chemostat •Turbidostat •Perfusion • 3 chambers with 500 uL volume each. • Mixing has an optimum period. • Tradeoff between turbulent flow and total flow rate. • Repeatable Inoculation. •Plastic to PDMS bonding - Plastic for dimensional stability - PDMS for active microfluidics Plastic to PDMS Bonding Process Full Deflection Membrane Mixer Bonding between Polycarbonate and PDMS Disposable Devices 2 Inches Growth Experiment with Microbioreactor OD pH Oxygen Flow Glucose Feed Microscale Continuous Cell Culture with Escherichia Coli. Continuous Culture Sequential Induction Performance Comparison Monitoring: Confocal Raman Spectroscopy Type Applikon 24 SIM Cell HTBR Ambr (TAP) This Work Bench Scale Source Chen 2009 Legmann 2009, Amanullah 2010 Kondragunta 2010 - Lee 2006 Lee 2011 Bareither 2010 Max Cell Density 2.6 x 106 cells/mL 12 x 106 cells/mL 2.3 x 106 cells/mL - - 3 x 107 cells/mL k La <30 h-1 7 h-1 0.9 h-1 - <500 h-1 1 – 15 h-1 Working Volume 5 – 6 mL 300 – 700 µL 35 mL 10 – 15 mL 1 – 3 mL 1 – 30 L Parallel 24 6 12 24 or 48 16 1 Control pH pH, Feed - pH, DO, Feed, T, DCO2 pH, DO, Feed, T, DCO2, OD pH, DO, Feed, T, DCO2 Online DO, pH DO, OD, pH pH, DO pH, DO pH, DO, DCO2, T, OD pH, DO, DCO2, T Incubator Yes Yes Water Bath Water Lines No No Agitation Shaker Rotator Rotator Propeller Membrane Deflection Propeller Bench Validation Yes Yes Yes - - - Comments 24 Deep Well Plate Cassettes on a Rotator Miniature Bioreactors Miniature Bioreactors Microfluidic Chip Bench Scale Bioreactors In situ bioprocess monitoring •Confocal Raman spectroscopy for cell culture metabolite monitoring in a microbioreactor. •Prediction of lactate and glucose concentration in Chinese hamster ovary (CHO) cell culture with confocal Raman spectroscopy. Confocal NIR Raman Spectroscopy Schematic •Confocal Raman spectroscopy integrated with microbioreactor can enable real-time nutrient and metabolite monitoring and lead to new control strategy. • Microbioreactor is suitable for small-volume (~ mL) biopharmaceutical production with tightly controlled fermentation environment. Lactate and Glucose Concentration Monitoring Current Development: Optical Induction Zone of Raman signal collection ~ 0.5 mm ~ 1.6 mm Acknowledgement Ram Lab Professor Rajeev Ram and Dr. Gajendra Singh Baseline Cu Inducer Lu Lab Professor Tim Lu, Dr. Pablo Perez-Pinera, and Fahim Farzadfard aTc Inducer Love Lab Professor Christopher Love, Dr. Kerry Love, Dr. Kartik Shah, and Nicholas Mozdzierz Schematic for the System Configuration Turbidostat OD Control Microbioreactor with Light Input Pharyx Inc. Dr. Harry Lee and Dr. Kevin Lee Sequential Induction • Saccharomyces Cerevisiae with duel inducible reporter proteins (RFP and YFP) cultivated inside microbioreactor in continuous cell culture mode. • Turbidostat control maintaining OD600 at 1. • Sequential induction with Cu and aTc inducers. Each inducer promotes the expression of the corresponding reporter protein. • Using light as signaling input for gene regulation. MIT Center for Biomedical Innovation BioMOD Team • Advantage: Fast dynamic response compared to signaling molecules such aTc. • Periodic optical illumination through microbioreactor chip. • Real-time fluorescence measurement with flow cells. Flow Cell for Fluorescence Measurement Funding Agent: DARPA