PELLETime_NPP - Northern Periphery Programme

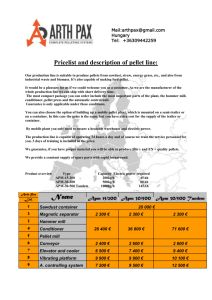

advertisement

Solutions for competitive pellet production in medium size enterprises North Karelia University of Applied Sciences Project Information • Project duration 1.1.2008 – 31.12.2010 • Priority 1: Promoting innovation and competitiveness in remote and peripheral area • Target areas: Finland, Sweden, Scotland and Iceland • Budget 1.77 MEUR • 9 main partners, 7 associate partners • Product: Tool package for SMEs to start small-scale pellet production Partnership Lead partner: North Karelia University of Applied Sciences (NKUAS Finnish Forest Research Institute (Metla) Joensuu Regional Development Company, Josek Ltd. University of Kuopio, The Fine Particle and Aerosol Technology Laboratory Oulu University of Applied Sciences Highland Birchwoods Swedish University of Agricultural Sciences Partnership Herads- and Austurlandsskogar Iceland Forest Service Associate partners: Vapo Corporation Ltd. Biottori Ltd. Pakaslahti Ltd. M. Pappinen Ltd. National Farmers Union Scotland JPK-Tuote Ltd Konepaja Antti Ranta Ltd. Justifications • Security of energy supply and preventing the climate change • Need to broaden the raw material base: • • • • • Rising domestic and export demand of pellets Economic fluctuations and shortage of current materials Preventing delays in market development Meeting both fuel and non-fuel demand of pellets Rural business development, innovativeness Objectives • The overall objective: Developing a package of tools to facilitate establishment of SMEs in small scale pellet production, support existing pellet production, and, enhance energy availability throughout the NPP region • Market analysis • Identification of current and future raw materials • GIS based ID of the bottlenecks of the raw materials supply • Investigating material handling and logistics • Development of new raw materials and mixtures • • Pelletizing trials and fuel analysis Potential of short rotational coppices/forestry crops Broadening of the raw material base PELLETime will identify current and future potential availability of both existing raw materials and alternative raw materials. GIS analysis will identify any bottlenecks arising from fluctuations in existing raw material supply over time and regional markets will also be analysed to highlight areas where these bottlenecks could become a significant constraint on market development. In these areas development of new raw materials will be vital and the project will examine the potential of a range of agricultural and short rotation forestry crops, developing best practice guidance on the landscape, biodiversity and hydrological dimensions of management. Material handling and logistics Handling, logistics and innovative techniques for matching variable raw materials to different end user requirements will be modelled and a cost-calculator will be developed to allow SMEs to assess the feasibility of local pellet production. In Iceland, PELLETime will provide expertise for developing local forest inventories and management plans. Pelletizing trials and fuel analysis Potential new raw materials and mixtures of raw materials will be pelletized and tested in terms of fuel quality, calorific value and emissions and the results will form the basis for a best practice guidance document on utilisation of different raw materials and mixtures in small and medium scale pellet production. PELLETime will carry out two rounds of pelletizing trials and test 12 samples of alternative raw materials, such as short rotational coppices, whole tree chips and logging residues from final fellings. Advisory, consultation and study tours PELLETime will organise open days for end users of pellets. Project will also carry out a range of advisory and consultation services, including business and technical advisory. Study tours will be organised for exchanging experiences and transferring best practices to the northern peripheral areas. Outcomes The SME tool package will comprise: – Pellet market report and contact network – Inventory of regionally available resources – Best practice guideline on landscape, biodiversity and hydrology of raw materials – Cost-calculator on handling and logistics of raw materials and pellets – Best practice guideline on logistics and quality assurance (in terms of fuel supply) – Best practice guideline on fuel quality and technology, and – Internet based user’s guide Contact PELLETime project Lasse Okkonen Project Manager, PELLETime project North Karelia University of Applied Sciences Yliopistokatu 6, FIN-80100 Joensuu FINLAND GSM (office) +358 50 342 3582 lasse.okkonen@pkamk.fi pelletime@pkamk.fi www.pelletime.fi