Wood Pellets: Clean, Efficient Heating with Renewable Energy from our Forest Resources

advertisement

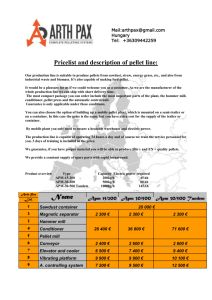

Wood Pellets: Clean, Efficient Heating with Renewable Energy from our Forest Resources Charlie Niebling, General Manager SURE Conference, Syracuse NY November 5, 2009 New England Wood Pellet Facilities Schuyler Wood Pellet LLC Jaffrey Plant and Biofuel Energy Systems Palmer Packaging and Reload Center Deposit p Wood Pellet LLC (October 2010) Jaffrey Plant Opened January, 1999 Palmer Packaging & Reload Center O Opened d October, O t b 2006 Schuyler Wood Pellet LLC Grand G a d Opening Ope g December ece be 7,, 2007 00 Making pellets is not a simple proposition Energy is One of the Big 21st Century Problems • Cheap, plentiful, and highly useful energy fueled the unprecedented economic growth of recent history • Pressure is mounting on the availability and price of such energy – Growing demand (e.g. India, China) – Dwindling supply (reserves, production/refining capacity) – Increasing environmental and geopolitical costs • Society is active in seeking economic and sustainable solutions – Most efforts aimed at high value areas of electricity & transportation (e.g. solar PV, wind, ethanol, biodiesel) • The e heat eat seg segment e t is sab big g oppo opportunity tu ty – Large, essential segment – ~30% of consumption, ~$200 billion annually – Largely unnoticed – has not received much attention compared to electricity & transportation BioPellets are a Promising Part of a Solution • Refined product of biomass – Made from waste wood, low-grade – Safe, clean, and inexpensive refining process – Consistent size, shape, and weight – Energy dense • Useful – Easily stored, distributed, and consumed – Ideal for heating and combined heat and power • Priced P i d competitively titi l vs. alternatives lt ti • You can feel good about using them – Renewable – Effectively carbon neutral – Locally produced Quick Overview of Manufacturing Process The manufacturing process begins when tractor trailer loads of raw material (wet and d dry d sawdust, d t shavings, chips etc.) arrive at the plant The plant. material is unloaded by a skid steer, steer a live livefloor or a truck dump. …and d here’s the Truck Dump Schuyler Wood Pellet One acre covered wood storage – will hold 6,000 tons A small percentage of our wood supply is coming from green whole tree chips; hi we are experimenting with screening to reduce bark and twig content to an acceptable level We are also experimenting with hardwood roundwood, with on-site flail debarking and chipping hi i later l t this fall The material is stored in piles until a front f t end d loader transfers it into the inin feed system. “Green” Green material averages about 45% moisture content. The in-feed system t meters it into a screener, which separates the chips and the sawdust. At this point, the chips pass through a 350 hp pregrinder and are mixed with the sawdust. The material then fills a silo which meters wood into the dryer. y The 12 12-foot foot diameter, 60foot long rotary kiln dryer dries the material to 10-12% moisture content. The dryer Th d is i heated h t d by a 45 MMBTU biomass burner. The burner is fueled by sawdust from a metering bin. Air is then blown into a series of cyclones which separate water vapor and d gases from the dried sawdust. Moist air is then exhausted. exhausted The sawdust is conveyed into a screener which separates the fine sawdust from the coarse. Now the coarse sawdust d t goes through th h another 300 hp grinding to be reduced in size size. The material is now conveyed to a silo where about 15% goes back to fuel the burner. The material in the silo is then metered into one of three 300 hp mills where the pellets are formed under d high hi h heat h t and d pressure. Pellets are about 4% moisture content content. The pellets travel through a cooling system. Once the O th pellets ll t have been cooled, they are then conveyed to a storage silo. Pellets are separated into 40pound bags and stacked by our robotic packaging system. t S Some product is diverted to our bulk delivery truck for delivery to central heating customers. Stacked pellets are then prepared for shipping. Pellets are then shipped to retailers throughout New England, NY and PA and on to over 60,000 end d users. Status of Pellet Industry in N h Northeast (NE & NY) • Approx Approx. 400 400,000 000 homes heated (primary or back-up) back up) with pellet fuel in Northeast; annual growth >10% • 13 manufacturers of pellet fuel in Northeast – 4 are startups facing typical start start-up up challenges, challenges 2 in ME are currently closed but will reopen • Total consumption approaching 600,000+ TPY; total manufacturing capacity about 400,000+ 400 000+ TPY • At least 7 new plants proposed (ME-2, NH-2, MA-1, VT-1, NY-2) • Limited distribution by bulk; 99.5% of fuel distributed in bags vs. <40% in Europe Pellet Fuels Ideally Suited to N th Northeastern t US M Market k t • Abundant, underutilized forest and agricultural resources; roundwood, roundwood chips chips, manufacturing residues – growing forest inventory and decline in pulp & paper manufacture; clean waste wood as well • Highest energy prices of anywhere in US • Huge thermal (heat) market, currently largely dependent on fossil energy (oil, natural gas, propane) – one third of total energy gy consumption p in the region g • Long tradition of using wood as fuel; aging demographics favor more convenience in burning wood • Population and demand density that enhances potential for bulk pellet fuel distribution • Generally favorable policy climate Heating with Pellet Fuels: Emerging E i Heating H ti Technology T h l and d Bulk B lk Fuel Distribution Options Pellet Stoves <85,000 BTU 30-50 lbs/day during winter Thermostatically controlled 145,000 in New England alone 1 million in U.S. The Future…..not that far off, but we e need eed help! ep 1. Home or Business Delivery of Pellets in Bulk - Much h like l k oil, l gas, or propane - Convenient - you don’t need to be there 3. Fully Automated Central Heating System - Boilers and furnaces support existing distribution system 2. Sufficient Storage - Automated feed system - 1-3 3 deliveries de e es a yea year - Self-ignition and self-cleaning - Attractive and/or unobtrusive - Safety that is superior to propane or gas 4. Easy Installation/Service - Simple p venting g - Simple, once-a-year maintenance includes ash removal New furnace, boiler technology beginning to expand central heating options; bulk delivery makes it possible, but delivery systems t nott well ll established t bli h d KWB (Austrian) Residential Boiler HARMAN BOILER TARM Austrian EnergyCabin: establishing North American sales Industrial combustion, district heating, combined heat and power…..HUGE potential in northeast Propell Energy • • • • • • Import, p , sell & service commercial boiler systems y 100-1,000 kW (340KBTU – 3.4 MMBTU) Swedish and Austrian technology Bulk fuel delivery Energy services Off Office buildings, schools, prisons, public works garages, apartment complexes, hospitals, shopping malls etc. Bulk delivery y Thermal Energy about One-Third of Total Energy Consumption in U.S. (source: EIA, 2004 data) 32 4 NH - 36% 32.4 NH – 34% 40 26.8 NH - 30% thermal transportation electricity • 80% of thermal energy is commercial/industrial; only 20% residential Drivers of Energy Policy • Efficiency • Emissions • Greenhouse Gases EFFICIENCY: Energy loss of different conversion technologies for woody biomass 90 Energy lo E oss ( % ) 80 70 60 Minimum 50 Maximum 40 30 20 10 0 Biopellet Thermal Biomass Electricity 2nd Gen. Biofuels (CE) Thanks to ProPellet Austria Source: USEPA and Swedish National Testing Institute Source: University of Wisconsin 2007 Source: University of Wisconsin, 2007 THANK YOU For more information: New England Wood Pellet LLC cniebling@pelletheat com cniebling@pelletheat.com www.pelletheat.com