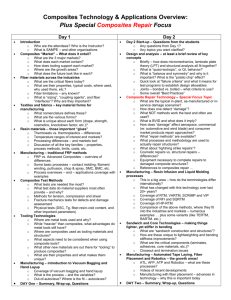

Recent Developments in High Performance Thermoplastic

advertisement

Recent Developments in HighPerformance Thermoplastic Composites Allan Murray, Ecoplexus Inc. Klaus Gleich, Southern Research Institute ACCE 2003 Overview • Introduction • Materials • Process Technology • Applications Why Use Composite Materials ? Specfic Tensile Properties of Polymer Matrix Composites 4.5 4 Continuous Unidirectional Carbon Composites 3 Glass & Carbon LFT & Continuous Other Fibers Varying Fiber Orientations 8 Specific Modulus (x10 in.) 3.5 2.5 2 1.5 LFT Carbon Composites Metals 1 0.5 Plastics Continuous Uni-directional Glass Composites LFT Glass Composites 0 0 1 2 3 Specific Strength (x106 in.) 4 5 6 Thermoplastic Composites Benefits Unique properties Vibration dampening Light weight Potential for low cost Shelf life Recyclable Durability Fatigue Corrosion Toughness Limitations Cost Materials Manufacturing Tooling Design know-how Manufacturing knowhow Use temperature Thermoplastic Composites Many Polymer Options Polyethylenes Polypropylenes Nylons Polycarbonates Acrylics Polyesters Polyimides Polysulfones Polyketones Polyurethanes the list continues Many Property Options ultimate strain > 100% no microcracking no delamination dampening no water uptake low dielectric properties melt formable weldable elastomeric - plastic - elastic behavior the list continues Cost Challenge Materials: Carbon Fiber / Epoxy, Carbon Fiber / BMI, Carbon Fiber / PEEK Processes: Hand Lay Up Costs in $/lb Typical Aerospace Structure $50 - $100/lb and more Apply Materials and Processing Techniques being Developed for Automotive Applications to Aerospace Applications Innovative Materials and Processes $5 - $20/lb Automotive Structures $1 - $3/lb Materials: Thermoplastic Woven Sheets, Glass, Carbon and Kevlar Fiber, Engineering Polymers Processes: Co-Compression Molding, CoInjection Molding, Thermoforming Materials: Glass Fiber / Polypropylene, SMC/BMC Processes: Compression Molding, Injection Molding High-Performance Thermoplastic Composites • Properties are fiber dominated • Oriented long or continuous fiber reinforcement • High volume fiber fraction (up to 65% by volume) Key benefits: • Reducing thermal limitations (e.g. creep) caused by the TP matrix system • Reducing costs and weight and retaining toughness, formability, weldability, short cycle times, recyclability benefits of the thermoplastic matrix Thermoplastic Materials Commercial Materials • GMT (Glass Mat Reinforced Thermoplastics) • Pultruded Products – LFT (Long Fiber Reinforced Thermoplastics) – CFT (Continuous Fiber Reinforced Thermopastics) • • • • • Wire coated products Commingled fibers Powder coated materials Film sticking Slurry processes Long-Fiber Thermoplastic Composites •New Hot-melt Process Produces Fully Wet-out Composite Products •Wide Range of Polymers and Fibers •Continuous Tape and Rod Products •Discontinuous Products with Any Fiber Length •Glass Products <$1.00/lb •Carbon Products <$8.00/lb Pilot Production for Thermoplastic Composites Short Fiber, Long Fiber and Continuous Fiber Composites Typical short fiber thermoplastic material, granules with fiber length of approx. 2 to 4 mm, resulting fiber length in a part of approx. 0.4 mm Long fiber thermoplastic material, pellets of ½” and 1 “ fiber length, resulting fiber length in a part of approx. 4-6 mm in injection molding and approx. 20 mm in compression molding Continuous reinforced thermoplastic material, tape used for woven sheets (thermoforming), filament winding or pultrusion Typical Pultruded Prepregs • Fiber: – E-glass, S-glass, Carbon, Aramid, polymer fibers • Matrix: – PE, PP, PA (6, 6/66, 12, …), PET, PBT, PC, PEI, PPS, SMA, blends, … • Fiber content: – 20% - 60% standard, some up to 84% • Product forms: – Tape, pellets (0.5”, 1”), woven tapes – more complex textile structures in development Twintex - The Commingling Concept Consolidated Composite Twintex® Prepreg Temperature + Pressure Source: Vetrotex Twintex – The Commingling Concept E Glass adapted sizing Plastic filament Additives : - coupling agent - UV stabilizer - natural or black Source: Vetrotex Twintex – The Manufacturing Process Extruder Bushing Glass TP Commingling Roving Source: Vetrotex Twintex - Commingled Fiber Products Specfic Tensile Properties of Polymer Matrix Composites • Fiber/matrix combinations: – E-glass/PP, E-glass/PET 4.5 4 Continuous Uni-directional Carbon Composites 3.5 3 Glass & Carbon LFT & Continuous Other Fibers Varying Fiber Orientations 2.5 • Fiber content: – 60 % and 75 % by weight • Product forms: – Roving, fabric, pellets Twintex 2 1.5 LFT Carbon Composites Metals 1 0.5 Plastics Continuous Uni-directional Glass Composites Twintex LFT Glass Composites 0 0 1 2 3 4 • Limitations: – Matrix material must be usable for a fiber spinning process limitations in MFI/viscosity, additive type and additive content 5 6 Physical Property Data Vetrotex Twintex Matrix Reinforcement wt.% reinforcement Orientation Density g/cm3 Tensile Strength MPa Tensile Modulus GPa Flexural Strength MPa Flexural Modulus GPa Flexural Elongation % Compression Strength MPa Shear Strength MPa Impact CHARPY un-notched kJ/m2 J/cm3 Heat deflection temp. (1.82 MPa) oC Specific Tensile Modulus (x10^8in) Specific Tensile Strength (x10^6in) PP glass 60 1/1 1.5 350 15 280 13 2.5 140 22.5 220 8 159 0.4 0.9 PP glass 60 4/1 1.5 500/180 24/8 380/160 18/6.1 2.5/3.6 230/100 24/15 330/90 11/3 159 0.6 1.3 Source: Saint-Gobain Vetrotex, “Twintex PP and PET Mechanical Properties (non standard)” PP glass 75 1/1 1.75 420 21 340 17.5 2.5 160 22.5 300 10 159 0.5 1.0 PP glass 75 UD 1.75 700 38 400 32 2 170 22.5 445 15 159 0.9 1.6 PET glass 65 1/1 1.95 440 25 600 22.5 3.25 410 43 300 10 257 0.5 0.9 Powder Impregnated Prepregs – The Hexcel TowFlex-Technology Fiber Creel Racks Fluidized Bed Powder Coating Chamber IR Oven Puller Take-up System To Weaving To Tapes To Pellets Charged Resin Powder Source: Hexcel Hexcel TowFlex Specfic Tensile Properties of Polymer Matrix Composites 4.5 • Typical fibers: • Typical resins: – PP, PA6, PPS, PEI, PEEK • Typical product forms: – – – – Flexible Towpreg Woven fabric Braided Sleeving Unidirectional Tape Continuous Unidirectional Carbon Composites Glass Carbon 3.5 Specific Modulus (x108 in.) – Carbon, E-glass, Sglass TowFlex 4 3 Glass & Carbon LFT & Continuous Other Fibers ` Varying Fiber Orientations Carbon Towflex 2.5 2 1.5 LFT Carbon Composites Metals 1 0.5 Plastics Glass Towflex Continuous Uni-directional Glass Composites LFT Glass Composites 0 0 1 2 3 4 6 Specific Strength (x10 in.) 5 6 Physical Property Data Hexcel Towflex Material Resin Content (weight %) Fiber volume (volume %) Composite density (g/cc) Flexural Strength D790 (MPa) Flexural Modulus D790 (Gpa) Tensile Strength D3039 (MPa) Tensile Modulus D3039 (26 Gpa) Compression Strength D695 (MPa) Compression Modulus D695 (Gpa) Specific Tensile Modulus (x10^8in) Specific Tensile Strength (x10^6in) TF-CN6100 TF-CPP100 TFF-CN6- TFT-CN6100 100 TFF-CPP- TFT-CPP100 101 TFFTF-EGN6- TFF-EGN6- TFT-EGN6- TF-CPPS- TFF-CPPS- TFT-CPPS- TF-EGPP- TFFTFT-EGPP- EGPPS100 100 100 103 103 103 101 EGPP-100 100 101 38 38 38 38 38 38 34 34 34 43 43 43 30 30 30 35 51 45 51 51 45 45 46 46 46 51 51 51 46 46 46 51 1.45 1.31 1.45 1.45 1.31 1.31 1.77 1.77 1.77 1.59 1.59 1.59 1.64 1.64 1.64 1.96 1517 627 827 1517 524 627 1034 517 1034 1724 869 1724 600 386 600 531 107 104 55 107 51 104 34 19 34 114 58 114 32 17 32 27 1655 821 1655 655 869 352 869 1655 869 1655 290 385 116 66 116 59 38 22 38 110 64 110 18 24 945 579 441 945 172 579 634 372 634 1055 448 1055 558 248 558 379 110 110 58 110 49 110 34 26 34 112 63 112 37 21 37 31 3.2 1.8 3.2 1.8 0.9 0.5 0.9 2.8 1.6 2.8 0.4 0.5 4.6 2.3 4.6 2.0 2.0 0.8 2.0 4.2 2.2 4.2 0.7 0.8 Source: Hexcel Composites (March 2003) www.Hexcel.com Process Technology Current Composite Materials and Processes Process Injection Molding Type of Application Low-Structural Components Compression Molding Semi-Structural Components Thermoforming Hand Lay Up / Vacuum Bag / Autoclave Structural Components Composite Performance versus Fiber Length 1.2 Fillers Short Fiber Long Fiber Continuous Relative Property Level 1.0 0.8 Modulus Strength Impact Processibility 0.6 0.4 0.2 0.0 0.1 1 Length (mm) 10 100 Source: OCF The Long Fiber Advantage • Stress is transferred to the fibers - the structural members of the composite • Long fibers create a “skeletal structure” within the molded article that resist distortion and provide unmatched strength, toughness, and overall performance Source: Ticona Continuous Fiber Advantage • In continuous oriented fibers the load is ultimately ‘fully’ transferred to the fiber • As a result tensile creep is limited in fiber direction Manufacturing Processes for HighPerformance TP-Composites • Low volume manufacturing processes – Discontinuous processes • • • • • Thermoforming Thermoplastic S-RIM, RTM and VARTM Thermoplastic filament winding Vacuum bag molding Net shape preforming (modified P4) Manufacturing Processes for HighPerformance TP-Composites • High volume manufacturing processes – Discontinuous processes • Injection molding with – LFT-pellets and concentrates (high performance resin/fiber combinations) – Inline compounding (high performance resin/fiber combinations) – Back molding / local reinforcement • Compression molding – LFT-pellets and concentrates (high performance resin/fiber combinations) – Inline compounding (high performance resin/fiber combinations) – Back molding / local reinforcement • Stamp forming – – – – Preheated preforms Matched metal tools Potential to manufacture very thin sections (0.5 to 1 mm) Drapable material required – Continuous processes • Pultrusion • LFT-extrusion Materials Used For Liquid Molding Processes Materials used for liquid molding processes – Cyclics – Reactive nylon – Fulcrum • Requirement for these materials – Viscosity less than 3000 mPa.s (cP) (better less than 1000 mPa.s (cP)) Cyclics • • • • • Cyclic form of PBT, PET, PC and others Only PBT commercial available Based on a ring shaped cyclical form One or two part systems Solid at room temperature – low viscosity resin at elevated temperature (approx. 150 cP) • Polymerize into the Polymer using a catalyst • Isothermal process • Typical process temperature: 180 – 200 oC Reactive Nylon For more information see presentation on “Reactive Thermoplastic VARTM/RTM/S-RIM” Fulcrum • ISOPLAST matrix (Dow proprietary engineering thermoplastic polyurethane) – Thermoplastic viscosity issues addressed by ability to reverse polymerization in the melt stage, reducing viscosity to ensure good impregnation – Repolymerizes upon cooling, retaining traditional thermoplastic composite advantages • High impact resistance • Recyclability • High elongation to failure (~2.5%, versus ~1-1.5% for thermosets) • Zero-emissions processing • Fulcrum is the combination of ISOPLAST and pultrusion, with specific hardware design • Provides 10-fold line speed improvement over typical thermoset pultrusion lines • Allows thermoforming, welding, and overmolding of finished pieces Thermoformed Fulcrum Components Figures from “Fulcrum Thermoplastic Technology; Making High-Performance Composite via Thermoplastic Pultrusion” Dow Plastics, January 2000 Physical Property Data Dow Fulcrum Matrix Reinforcement v.% reinforcement Density g/cm3 Tensile Strength MPa Tensile Modulus GPa Elongation at Break % Flexural Strength MPa Flexural Modulus GPa Longitudinal Flexural Strength MPa Longitudinal Flexural Modulus GPa Transverse Flexural Strength (MPa) Compressive Strength Compressive Modulus Specific Tensile Modulus (x10^8in) Specific Tensile Strength (x10^6in) Polyurethane Polyurethane Polyurethane Polyurethane glass glass glass glass 76.6 (wt.) 45 55 66 (wt.) 1.91 1.74 1000 980 45 43 2.5 1.5 1150 1050 48 40 1080 1340 35 44 151 122 151 790 430 440 46 35 35 0.9 2.1 45v.% and 55v.% data from Matweb.com 76.6wt.% and 66wt.% data from “FULCRUM: Thermoplastic Composite Technology, Making High-performance Composite via Thermoplastic Pultrusion” Dow Plastics, January 2000 Reactive Thermoplastic VARTM/RTM/S-RIM • Similar the thermoset process • Reaction of at least two components creates a thermoplastic resin that can be melted, preshaped, welded, … • Low viscosity is required • Possible materials: Nylon, TPU, C-PBT (Cyclics) Problems Connected With Thermoplastic RTM • Reaction can be stopped or made incomplete by – Moisture – Chemicals in fiber sizing • Most of the thermoplastic compatible sizings are not developed for such type of processes • Availability of compatible sizings in form of fabric is very limited – Oxygen • Only limited support of material manufacturers • Material costs (in case of c-PBT) Thermoforming Heat in Oven Thermoforming Operation Finished Product Thermoforming • Weight performance: – Good weight/performance ratio for fabric reinforced sheets due to continuous fibers – Reduced weight/performance ratio for extruded sheets depending on the resulting fiber length • Design flexibility: – Limited, especially for complex geometries – Simulation tools available • Processability: – Stabilization against oxidation necessary – Fiber disalignments with continuous fibers possible depending on geometry, material, tooling and process conditions • Recyclability: – High rate of production scrap (fixation) – No direct recyclability – Use in other processes like plastication of regranulation TP S-RIM, RTM, VARTM • Weight/performance: – Excellent • Design flexibility: – Limited to preforming capability, flow length and flow behavior of the resin • Processability: – Reaction can be sensitive to moisture and fiber sizing • Recyclability: – Production scrap due to preforming step depending on preforming method – No direct recyclability; can be used in other processes TP Filament Winding • Weight/performance: – Excellent • Design flexibility: – Limited to symmetric parts that can be wound on a mandrel • Processability: – Higher oxidative stabilization required • Recyclability: – Low rate of production scrap – No direct recyclability – Scrap can be used in other processes Vaccum Bag/ Hand Lay-Up • Weight/performance – Excellent due to continuous fiber reinforcement • Design flexibility – Limited to drapability and to the posibility of manually lay up • Processability – Higher void content due to low pressure consolidation – Using autoclave to reduce void content – Often fiber disalignments • Recyclability – High rate of production scrap possible depending on the size of the material sheets and the part geometry – No direct recyclability – Scrap can be reused in other processes LFT-Injection Molding • Weight/Performance – Lower end of thermoplastic composites due to reduced fiber length in the final part – Improvements possible by using local reinforcements (using pultruded sections, sheets or tapes of continuous composites localized strengthening and stiffening, reduction of warpage) • Design Flexibility – High – Flow channels and positions of gates have to be carefully designed • Processability – Highly stable • Recyclability – Low production scrap rate – Can be reused in the same process Compression Molding • Weight/Performance – Medium – Retaining fiber length gives excellent properties for a random oriented material, but is lower than using a fabric – Local reinforcement or fabric reinforced GMT improve it (using pultruded sections, sheets or tapes of continuous composites localized strengthening and stiffening, reduction of warpage) • Design flexibility – High – Special simulation tools available • Processability – Very stable process • Recyclability – Some production scrap due to trim operations – Scrap can be added and reused in the same process (GMT only sheets can be reused in the same process, but not recommended) Curv • Self-reinforced polypropylene • Consists of “hot compacted” polypropylene fiber or tape – Surface of tape or fiber melts during compaction to form the “matrix” that binds the directional elements together • Oriented morphology provides over six-fold increase in tensile strength and nearly 5-fold increase in tensile modulus over isotropic polypropylene, with ~2% weight penalty • Nearly doubles tensile strength of 40% random mat short glass polypropylene, with comparable modulus and 22% weight savings • Elimination of glass reinforcement has several advantages: – – – – – Increased recyclability Reduced weight Lower temperatures and pressures for thermoforming Reduced irritation in the workplace High strain to failure, with good impact strength Data from “A New Self-Reinforced Polypropylene Composite” Jones, Renita S. and Derek E. Riley Physical Property Data Curv Density g/cm3 Tensile Modulus GPa Tensile Strength MPa Heat deflection temperature oC Notched Izod impact J/m 455 KPa 1820 KPa +20oC -40oC Thermal expansion / oC x 10-6 Specific Tensile Modulus (x10^8in) Specific Tensile Strength (x10^6in) from BP document “A New Self-Reinforced Polypropylene Composite” Jones, Renita S. and Derek E. Riley, 2002 0.92 5 180 160 102 4750 7500 41 0.2 0.8 Pultrusion • Weight/performance – Good to excellent due to continuous reinforcement • Design flexibility – Low design flexibility – Limited to constant cross sections, but can be shaped (pull/press) • Processability – Only limited experience available – Depends on stabilization of the material as well as used material form • Recyclability – Low rate of production scrap expected – No direct recyclability – Can be used in other processes LFT-Extrusion • Weight/performance – Medium weight performance – Depends on retaining fiber length • Design flexibility – Low design flexibility – Limited to constant cross sections – Can be post shaped or pull formed • Processability – Not a lot of experience – A stable process is expected using the right die design • Recyclability – Low rate of production scrap – Can be reused in the same process Economics Process Cycle Time Tooling Costs Scrap Rate Overall Economics Thermoforming Medium Low High Good for low volume production with no or limited thickness variation TP S-RIM, RTM, VARTM Medium to long, up to several minutes VARTM: low, single sited tool RTM: low to medium S-RIM: Medium Depends on preforming technique; often high for complex shaped parts Good for low volume production TP Filament Winding Medium to long, depending on number of tapes and heating system Low to medium Low Good for symmetrical parts in low to medium volume production Vacuum Bag/ Hand Lay-up Long; manual preparation can be hours for a part Low, single sided tool Medium to high Good for prototyping. Not recommended for production scale. Injection Molding -LFT -ILC Short cycle times; typically 50 – 80 sec. High; steel tools with ejector pins and slides Very low Excellent for high volume production Compression Molding -GMT -LFT -ILC Short cycle times; typically 35 – 60 sec. High; steel tools with ejector pins and slides Low – medium depends on cut outs. Scrap can be reused Excellent for high volume production of large components Pultrusion Continuous process; not enough experience on throughput Medium Low Limited experience available Extrusion Continuous process; throughput mainly limited by cooling capacity of calibration die Medium to high Low Expected to be cost effective for profiles Applications Applications For High-Performance Thermoplastic Composites • Aerospace and defense: – Radomes, wing and fuselage sextions, anti-ballistics • Infrastructure and Construction – Window profiles, rebar, beams, structures, composite bolts • Consumer / recreational – Orthotics, safety shoes, sporting goods, helmets, personal injury protextion, speaker cones, enclosures, bed suspension slats • Auto and truck – Bumper beams, skid plates, load floor, seat structures • Transportation – Railcar structure, body structure and closures • Energy production and storage – Oil and gas structura tube, wind turbines BMW M3 Bumper Beam - Beam and crush columns manufactured using Hexcel TowFlex PA6 - Parts welded by high frequency vibrational welding - 2 versions: Source: Jacob Kunststofftechnik GmbH & Co. KG www.jacob-kunststofftechnik.de Standard M3 based on glass fiber reinforcement (approx. 40 cars / day) M3 CSL (limited to 1600 total) using Carbon fiber reinforcement Helmets Military helmet for Norwegian Army Made by Cato Composites 50,000/year TEPEX antiballistic 302 Aramid/PA6 continuous reinforcement Source: Bond-Laminates GmbH www.bond-laminates.com White water helmet Made by Prijon TEPEX dynalite 701 Glas, Carbon, Aramid/PA6.6 Continuous reinforcement Source: Bond-Laminates GmbH www.bond-laminates.com Aircraft Applications Fixed wing leading edge for Airbus Fokker Special Products/Airbus TEPEX semipreg 107 Non fully consolidated, flexible layers of continuous fiber reinforced thermoplastics Glass/PPS Wing access panel for Airbus Fokker Special Products/Airbus TEPEX semipreg 207 Non fully consolidated, flexible layers of continuous fiber reinforced thermoplastics Carbon/PPS Mine Sweeper Armouring •Made from TEPEX antiballistic 302 •Aramid/PA6 •Continuous reinforced •Made by Kvaerner Source: Bond-Laminates GmbH www.bond-laminates.com Safety Shoes • Composite Toecap – History: • Composite Toecaps were manufactured in the past using GMT with 50% fiber glass content • Changing the regulations, this was not sufficient to meet the 200 J requirement – Newer development: • • • • 65 g / piece (metal 105 g /piece) 200 J resistance Made from Twintex and LFT, 60% fiber glass, PP Manufactured by Security Composites Ltd. (UK) Others • GF/PP composite tank Produced by Covess (Belgium) using Twintex and GMT, welded out of 3 pieces and designed to withstand pressure to 100 bar • Evaluation of thermoplastic composite rebars made with the Fulcrum process • Thermoplastic composite bolts made by Clickbond Inc. using a thermoforming approach • Loudspeaker cones, electronic housings and lightweight carbon fiber reinforced structural applications for the automotive industry made by Centrotec AG • Prototype of a continuous fiber reinforced PP boat (JEC 2000 Innovation Award) made from Twintex using vaccum bag molding. Developed by Halmatic, Ltd. • Golf club shafts made from PPS/carbon prepreg tape with 66 – 68% fiber content. Multi-step operation including a table rolling, a compression and an oven consolidating step. Manufactured by Phoenixx TPC. The Future of Thermoplastic Composites • Will go to more structural applications using different technical thermoplastics in combination with glass, carbon and synthetic fibers. • Will replace metal applications and reduce weight. • Improved processing methods will be developed and applied. Conclusions • High-performance thermoplastic composites with fiber-dominated properties are a way to – – – – lower cost higher performance short cycle times Recyclability • Pre-impregnation can improve wet out and performance over commingled prepregs • Materials and manufacturing methods are available Acknowledgements • Aaron Brice and Erik Nolte, Stewart Automotive Research, LLC