Day_35 - Rose

advertisement

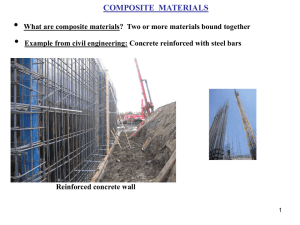

DAY 35: MAKING COMPOSITE MATERIALS Some Matrix Materials Manufacturing Methods Structural Composites BOEING 767 AIRBUS A380 http://www.airporttech.tc.faa.gov/safety/patterson2.asp http://www.hsc.csu.edu.au/engineering_studies/aero_eng/2579/polymer_composites.html COMPOSITE PROPERTIES (EPOXY MATRIX) VF=0.6 BORON FIBERS ARE AN UNCOMMON ADDITION – THEY ARE LARGE AND INFLEXIBLE Epoxy Boron Graphite http://www.metallographic.com/Procedures/Applications.htm BORON FIBER - CHEMICAL VAPOR DEPOSITION ON A TUNGSTEN WIRE http://www.specmaterials.com/boronfiber.htm CARBON FIBER (HEXCEL) http://www.hexcel.com/NR/rdonlyres/225E3CA5-965B-4B29-9A920CE184B1DDF3/0/CarbonFiber_SelectorGuide.pdf CARBON FIBERS (TORAY) http://www.toraycfa.com/pdfs/Torayca SummaryDataSheet.pdf http://www.fibraplex.com/tow.asp CARBON EPOXY COMPOSITE PROPERTIES http://www.hexcel.com/NR/rdonlyres/225E3CA5-965B-4B29-9A920CE184B1DDF3/0/CarbonFiber_SelectorGuide.pdf COST COMPARISON MATRIX MATERIALS FOR COMPOSITES 1. 2. 3. 4. Function and Properties of the Matrix Material Binding fibers together into a shape Protect the fibers from damage Serve as a barrier to failure. If an individual fiber fails, the failure will not spread. Be very easy to bond to fiber The matrix materials are usually polymers and are the”weak link” as far as operating temperatures are concerned. LIST OF MATRIX MATERIALS, SOMETIMES CALLED “RESINS” Polyester Vinyl ester Epoxy Phenolic PEEK POLYESTER Very common polymer family. It can be thermoplastic and in this form is a common synthetic fiber. Unsaturated polyesters are used in producing thermosets, (copoymerization with styrene) which are used as matrix materials. Mostly in fiberglass. The bond is strong, and is particularly good at resisting water and chemical attack. Cheap VINYL ESTERS Better than polyester, but a little more expensive. Gives upper end fiberglass. Glassair – first composite kit airplane. EPOXY We have already discussed this one, a top of the line thermoset, very commonly used in aerospace composites. OTHERS Phenolics, high strength thermosets. Very good adhesives and high temperature uses. PEEK. PEI (polyetherimide) PPS (polyphynolene sulfide) Very strong. Good at higher temperatures. This is a thermoplastic. In recent years, thermoplastic matrix materials have seen increased use. Tough, damage resistant, can be welded! FABRICATION PROCESSES Pultrusion Filament winding Prepreg and Lay up PULTRUSION Quick, inexpensive way to make long fiber oriented composites. Fibers oriented. For the kind of stuff you make by extrusion. Hollow core is possible. PULTRUSION IMAGES http://www.henanpolymer.com/english/frp1.html http://www.aims-intl.com/images/grating___pultruded.gif FILAMENT WINDING Filaments are carefully wound onto a mandrel after being wetted with resin. When the desired number of windings is obtained, the object may be cured. The manufactured object will often be cylindrical in shape. FILAMENT WINDING IMAGES http://www.adoptech.com/pressure-vessels/main.htm http://imghost.indiamart.com/data/T/P/MY-718936/filamentwound-frp-pipes_10676686_250x250.jpg http://www.gilgwang.com/english/frp/img/grp03.gif PREPREG AND LAYUP You will see sheets of prepreg. They consist of the fiber and the uncured resin, with paper backing. The sheets are applied, often by hand to a form, where they adhere. This is often done by hand, by expert workers. Then cure. IMAGES Prepreg must be stored at low temp. to avoid curing or drying out. COMPOSITE MADE BY LAY UP STRUCTURAL COMPOSITES Sandwich Composites are an example of how different parts of a beam, plate or shell structure can be made in layers, in which each layer performs a function. •SANDWICH TYPES OF HONEYCOMB Aramid Fiber (Nomex®/Kevlar®) Aluminum Stainless Steel Thermoplastic Polycarbonate Polypropylene PVC SAN PE ABS http://www.plascore.com/product-honeycomb-cores.htm?gclid=CJK_5_HP6p8CFQoNDQodExVGYg http://www.azom.com/details.asp?ArticleID=1092#_Honeycombs APPLICATION: TOYOTA EAGLE 987 Fuselage is carbon fiber honeycomb composite GLARE GLARE is used in aerospace structures. It is a composite in which layers of aluminum and fiberglass prepreg sheets are bonded together by epoxy. Why not use carbon fiber? The fibers are aligned in a way which is most favorable for load carrying. Once fabricated, GLARE is then processed in much the same way that aerospace aluminum is. GLARE IMAGES (HYBRID COMPOSITE) Outer layers of Aluminum act as protective barriers. Water absorption can be a problem. Here is reduced USE OF GLARE