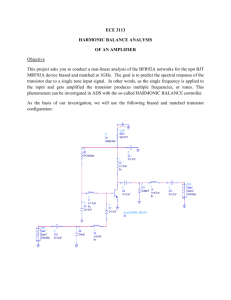

asdfasdfasdf - University of California, Santa Barbara

advertisement

Plenary, 2008 IEEE-CSIC Symposium, October 12, 2008

THz Bipolar Transistor Circuits:

Technical Feasibility,

Technology Development,

Integrated Circuit Results

Mark Rodwell

University of California, Santa Barbara

Coauthors

E. Lobisser, M. Wistey, V. Jain, A. Baraskar, J. Koo

University of California, Santa Barbara

E. Lind

Lund University

Z. Griffith, J. Hacker, M. Urteaga, D. Mensa, Richard Pierson, B. Brar

Teledyne Scientific Company

rodwell@ece.ucsb.edu 805-893-3244, 805-893-5705 fax

The End is

( ! ) Law) is Near (?)

(ofNear

Moore's

It's a great time to be working on electronics !

Things to work on:

InP HEMTs & HBTs: extend (ft , fmax) to 2-3 THz, build THz ICs

GaN HEMTs: develop V- and W-band power amplifiers

Si MOSFETs: work to keep them scaling past 22 nm

CMOS IC design: build ICs which bury the III-V's

InGaAs MOSFETs: help keep VLSI scaling (maybe)

Scaling for

THz Transistors

Simple Device Physics: Resistance

bulk resistance

R

bulk T

A

contact resistance

-perpendicular

R

contact

A

contact resistance

- parallel

R

contact

A

W'

sheet

3L

Good approximation for contact

widths less than 2 transfer lengths.

Simple Device Physics: Depletion Layers

capacitance

A

C

T

transit time

T

t

2v

space-charge

limited current

I max 2v

2 Vapplied Vdepletion 2

A

T

V

C

t

I C

where

T

I max Vapplied Vdepletion 2

Simple Device Physics: Thermal Resistance

Exact

Carslaw & Jaeger 1959

Long, Narrow Stripe

HBT Emitter, FET Gate

1

1

L

Rth

ln

Kth L W Kth L

cylindrica l heat flow

spherical heat flow

near junction

far from junction

Square ( L by L )

IC on heat sink

1

L

Rth

sinh 1

Kth L

W

1

W

sinh 1

KthW

L

Rth

1

1

4 K th L K th L

planar heat flow spherical heat flow

near surface

far from surface

Simple Device Physics: Fringing Capacitance

C

W

1 .5

L

T

parallel - plate

fringing

wiring capacitance

C/L

VLSI power-delay limits

slowly - varying function

C

of

W

/

G

and

W

/

G

L

1

2

(1 to 3)

FET parasitic capacitances

C parasitic / L ~

FET scaling constraints

Frequency Limits

and Scaling Laws

of (most)

Electron Devices

t thickness

C area / thickness

Rtop contact / area

Rbottom

contact

area

PIN photodiode

Rtop

sheet width

4

Rbottom

length

I max, space-charge-limit area / thickness

2

power

length

T

log

length

width

To double bandwidth,

reduce thicknesses 2:1

Improve contacts 4:1

reduce width 4:1, keep constant length

increase current density 4:1

Bipolar

Transistor

Design

Bipolar Transistor Design

We

Tb

t b T 2 Dn

2

b

Wbc

Tc

t c Tc 2v sat

Ccb Ac /Tc

I c ,max vsat Ae (Vce,operating Vce,punch-through) / T

2

c

P

T

LE

Le

1 ln

We

Rex contact /Ae

We Wbc contact

Rbb sheet

12 Le 6 Le Acontacts

emitter

length LE

Bipolar Transistor Design: Scaling

We

Tb

t b T 2 Dn

2

b

Wbc

Tc

t c Tc 2v sat

Ccb Ac /Tc

I c ,max vsat Ae (Vce,operating Vce,punch-through) / T

2

c

P

T

LE

Le

1 ln

We

Rex contact /Ae

We Wbc contact

Rbb sheet

12 Le 6 Le Acontacts

emitter

length LE

Bipolar Transistor Scaling Laws

We

Tb

Changes required to double transistor bandwidth:

parameter

collector depletion layer thickness

base thickness

emitter junction width

collector junction width

emitter contact resistance

current density

base contact resistivity

emitter

Wbc

Tc

length LE

change

decrease 2:1

decrease

1.414:1

decrease 4:1

decrease 4:1

decrease 4:1

increase 4:1

decrease 4:1

Linewidths scale as the inverse square of bandwidth because thermal constraints dominate.

Thermal Resistance Scaling : Transistor, Substrate, Package

Tsubstrate

cylindrica l heat flow

spherical flow

planar flow

near junction

for r Le

for r DHBT / 2

L

P 1 1

P Tsub D / 2

ln e

K InP LE We K InP LE D K InP

D2

P

increases

insignific ant

increases quadratica lly

logarithmi cally

variation

if Tsub is constant

1 1 Pchip

Tpackage

4 KCuWchip

junction temperature rise, Kelvin

140 Tsub 40 m (150 GHz / f clock )

120

Wiring lenghts

total

2000 - HBT CML IC

scale as

100

80

1/bandwidt h.

substrate: cylindrical+spherical regions

60

scales as

substrate: planar region

20

0

100

Power density,

package

40

(bandwidth ) 2 .

200

300

400

500

600

master-slave D-Flip-Flop clock frequency, GHz

700

Thermal Resistance Scaling : Transistor, Substrate, Package

Tsubstrate

cylindrica l heat flow

spherical flow

planar flow

near junction

for r Le

for r DHBT / 2

L

P 1 1

P Tsub D / 2

ln e

K InP LE We K InP LE D K InP

D2

P

increases

insignific ant

increases quadratica lly

logarithmi cally

variation

if Tsub is constant

1 1 Pchip

Tpackage

4 KCuWchip

junction temperature rise, Kelvin

140 Tsub 40 m (150 GHz / f clock )

120

Wiring lenghts

2000 - HBT CML IC

Probable

best solution:

scale as

1/bandwidt h.

Thermal Vias ~500 nm below InP subcollector

Power density,

...over full active IC area.

scales as

total

100

80

substrate: cylindrical+spherical regions

60

package

40

substrate: planar region

20

0

100

(bandwidth ) 2 .

200

300

400

500

600

master-slave D-Flip-Flop clock frequency, GHz

700

InP Bipolar Transistor Scaling Roadmap

industry university university appears

→industry 2007-8

feasible

maybe

emitter 512

16

256

8

128

4

64

2

32 nm width

1 m2 access

base

300

20

175

10

120

5

60

2.5

30 nm contact width,

1.25 m2 contact

collector 150

4.5

4.9

106

9

4

75

18

3.3

53

36

2.75

37.5 nm thick,

72 mA/m2 current density

2-2.5 V, breakdown

520

850

430

240

730

1300

660

330

1000

2000

1000

480

1400 GHz

2800 GHz

1400 GHz

660 GHz

ft

fmax

power amplifiers

digital 2:1 divider

370

490

245

150

We

Tb

Wbc

Tc

Can we make a 1 THz SiGe Bipolar Transistor ?

InP

emitter 64

2

SiGe

18

1.2

nm width

m2 access

56

1.4

nm contact width,

m2 contact

collector 53

36

2.75

15

125

???

nm thick

mA/m2

V, breakdown

ft

fmax

1000

2000

GHz

GHz

Simple physics clearly drives scaling

transit times, Ccb/Ic

→ thinner layers, higher current density

high power density → narrow junctions

base

small junctions→ low resistance contacts

Key challenge: Breakdown

15 nm collector → very low breakdown

(also need better Ohmic contacts)

64

2.5

1000

2000

PAs

1000 1000

GHz

digital 480

480

GHz

(2:1 static divider metric)

Assumes collector junction 3:1 wider than emitter.

Assumes SiGe contacts 2:1 wider than junctions

HBT Design For IC Performance

from charge-control analysis:

Tgate ( VL / I C )( C je 6Ccbx 6Ccbi ) t f

( kT / qI C )( 0.5C je Ccbx Ccbi 0.5t f I C / VL )

Rex ( 0.5Ccbx 0.5Ccbi 0.5t f I C / VL )

Rbb( 0.5C je Ccbi 0.5t f I C / VL ).

InP HBT: Status

InP DHBTs: September 2008

400 500

GHz GHz

1000

600

GHz

900

GHz

800

GHz

700

GHz

Teledyne DBHT ( ft f max ) / 2

125 nm

UIUC DHBT

800

NTT DBHT

max

(GHz)

250 nm

f

popular metrics :

ft or f max alone

ft f max

ft f max

(1 ft 1 f max ) 1

ETHZ DHBT

600

UIUC SHBT

250 nm

UCSB DHBT

400

NGST DHBT

600nm

HRL DHBT

IBM SiGe

200

350 nm

Vitesse DHBT

much better metrics :

power amplifiers :

PAE, associated gain,

mW/ m

low noise amplifiers :

Fmin , associated gain,

digital :

f clock , hence

(Ccb V / I c ),

Updated Sept. 2008

0

0

200

400

600

ft (GHz)

800

1000

( Rex I c / V ),

( Rbb I c / V ),

(τb τc )

512 nm InP DHBT

500 nm mesa HBT

150 GHz M/S latches

175 GHz amplifiers

Laboratory

Technology

UCSB / Teledyne / GCS

UCSB

500 nm sidewall HBT

DDS IC: 4500 HBTs

20-40 GHz op-amps

Teledyne

Teledyne / BAE

Teledyne / UCSB

Production

( Teledyne )

Z. Griffith

M. Urteaga

P. Rowell

D. Pierson

B. Brar

V. Paidi

ft = 405 GHz

fmax = 392 GHz

Vbr, ceo = 4 V

20 GHz clock

53-56 dBm OIP3 @ 2 GHz

with 1 W dissipation

40

H

mA/m2

10

30

dB

256 nm Generation

InP DHBT

150 nm thick collector

U

21

20

f

10

max

= 780 GHz

t

10

10

10

11

2

3

4

5

12

11

10

20

21

2

mA/m

dB

10

max

1

V

U

f

0

12

10

ce

10

10

10

9

10

H

20

4

0

Hz

70 nm thick collector

30

6

2

f = 424 GHz

0

9

10

8

= 560 GHz

15

10

5

f = 560 GHz

t

324 GHz

Amplifier

0

0

9

10

10

10

11

10

0

12

10

1

2

V

Hz

3

4

ce

60 nm thick collector

40

30

H

30

2

U

mA/m

dB

200 GHz

master-slave

latch design

21

20

10 fmax = 218 GHz

20

10

f = 660 GHz

Z. Griffith, E. Lind

J. Hacker, M. Jones

t

0

9

10

10

10

11

10

Hz

10

12

0

0

1

2

V

ce

3

324 GHz Medium Power Amplifiers in 256 nm HBT

ICs designed by Jon Hacker / Teledyne

Teledyne 256 nm process flowHacker et al, 2008 IEEE MTT-S

Gain (dB), Power (dBm), PAE (%)

20

10

40

Output Power (dBm)

Gain (dB)

Drain Current (mA)

PAE (%)

30

0

20

-10

10

-20

-20

0

-15

-10

-5

Input Power (dBm)

0

5

Current, mA

~2 mW saturated output power

128 / 64 / 32 nm

HBT Technologies

Conventional ex-situ contacts are a mess

THz transistor bandwidths: very low-resistivity contacts are required

textbook contact

with surface oxide

with metal penetration

Interface barrier → resistance

Further intermixing during high-current operation → degradation

Improvements in Ohmic Contacts

128 nm generation requires ~ 4 - μm2 emitter & base resistivities

64 nm generation requires ~ 2 - μm2

Contacts to N-InGaAs*:

Mo

MBE in-situ

0.3 (+/- 0.7) - μm2

TiW

ex-situ / NH4 pre-clean

~1 to 2 - μm2

variable between process runs

Contacts to P-InGaAs:

Mo

MBE in-situ

Pd/Ti...

ex-situ

below 2.5 - μm2

~4 - μm2

*measured emitter resistance remains higher than that of contacts.

Mo Emitter Contacts: Robust Integration into Process Flow

Proposed Process Integration:

Process Must Change Greatly for 128 / 64 / 32 nm Nodes

control undercut

→ thinner emitter

thinner emitter

→ thinner base metal

Undercutting of emitter ends

{101}A planes: fast

{111}A planes: slow

thinner base metal

→ excess base metal resistance

128 nm Emitter Process: Dry Etched Metal & Semiconductor

a

b

Litho

Cr

pattern

metal

c

SF6/Ar ICP

SiNsidewall

x sidewall

d

e

dry/N

etch

Cl

2 2 ICP

Wetetch

Etch

wet

HCl:H3PO4

BHF

SiO2

TiW

Ti

InGaAs n++

InGaAs n++

InGaAs n++

InP n

InP n

InP n

InP n

InGaAs p++ Base

InGaAs p++ Base

InGaAs p++ Base

InGaAs p++ Base

InGaAs p++ Base

12

20

H

21

10

max

mA/m

f

2

U

20

dB

10

11

10

10

30

10

9

10

Recent Results @ 128 nm emitter width to be submitted

= 560 GHz

15

10

5

f = 560 GHz

t

0

9

10

0

10

10

11

10

Hz

results @ c.a. 200 nm emitter metal width

12

10

0

1

2

V

ce

3

4

Planarization E/B Processes for 64 & 32 nm

Planarization boundary

What about InGaAs HEMTs ?

...& InGaAs MOSFETS ?

InGaAs HEMTs and InGaAs MOSFETs

high-K

gate barrier

Source

Gate

N+ source/ drain

by MBE regrowth

Drain

K Shinohara

sub-22-nm InGaAs MOSFETs being developed for potential use in VLSI

Efforts may: improve understanding HEMT & MOSFET scaling limits

produce process modules which aid THz HEMTs

Key III-V MOSFET scaling limits:

low density of states→limits gm→ Cfringing/gm does not scale

low m* → high well energy → minimum well thickness

Additional HEMT scaling limits:

high access resistance: barriers, recess regions, contacts

limits to sheet concentration from small hetero-barrier energy

HBT Applications

Applications of THz InP HBTs

Mixed-Signal ICs (ADCs, DACs, DDS)

benefit in high-clock-rate ICs with 1k-3k devices

lack of CMOS integration a major limitation

→ Mark Rosker's talk

Precision GHz analog ICs using THz transistors

→ Sanjay Raman's talk , Zach Griffith's talks

mm-Wave Power: 60 GHz & up

GaN threatens, but fmax→ gain → PAE

600-1000 GHz transceiver ICs

for low-volume military / scientific applications

Few-THz Bipolar Transistors

THz InP Bipolar Transistors: can it be done ?

Scaling limits: contact resistivities, device and IC thermal resistances.

62 nm (1 THz ft , 1.5 THz fmax ) scaling generation is feasible.

700 GHz amplifiers, 450 GHz digital logic

Is the 32 nm (1 THz amplifiers) generation feasible ?

THz InP Bipolar Transistors: what would we do with it ?

Mixed-Signal IC Power density & CMOS integration are serious challenges

Precision GHz analog systems

mm-wave power

Sub-mm-wave electronics