Process Management and TQM

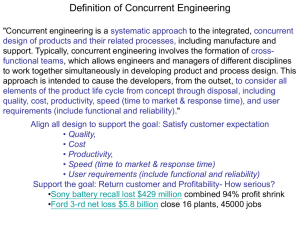

advertisement

HUMAN RESOURCES – YEAR 2 TQM – YEAR 4 Production Staffing Schedule Able Amos Unit Sales Forecast 1,600 Inventory On Hand - Production Schedule 1,600 Production After Adj. 1,584 NA NA NA TOTAL 675 - - - - - - - 675 569 0 - 0 - 2,275 0 - STAFFING Needed Complement Complement 2,153 2nd Shift Complement 86 203 100.0% 0.0% 0.0% 0.0% Turnover Rate Labor Cost/Unit $10.65 $15.07 $0.00 $0.00 $0.00 New Employees Material Cost/Unit $14.85 $13.14 $0.00 $0.00 $0.00 Separated Employees Total Unit Cost $25.51 $28.21 $0.00 $0.00 $0.00 Recruiting Spend Contribution Margin 26.1% 29.5% 0.0% 0.0% 0.0% Training Hours TOTAL Buy/Sell Capacity 150 Automation Rating 4.0 New Autom. Rating 5.0 2.7 0.0 0.0 0.0 $7,100 $3,220 $0 $0 $0 Investment ($000) A/P Lag (days) 30 - 50 1.0 0 - 0 - Productivity Index 0.2% 0.0% 10.0% 10.0% 24 207 8 0 $0 $0 0 0 100.0% 100.0% 1,150 0 200 - Max Invest. 100% 203 100.0% 350 100% 406 154 2nd shift/Overtime% 800 240 1st Shift Complement Overtime% 1st Shift Capacity This Year 2,275 Margins Physical Plant Last Year $10,320 $10,697 Recruiting Cost $207 Separation Cost $0 Training Cost $0 Total HR Admin Costs $207 Total Quality Management Yearly investments of < $250,000 will create little improvement Yearly investments above $750,000 pushes into diminishing returns Investments of > $1,000,000 in a year produces no absolutely additional benefits Investing more than $2,000,000 in the same initiative over 2- 3 year period creates little or no additional improvement Process Management Initiatives These initiatives improve business procedures, resulting in improved efficiencies and cost structures CPI (Continuous Process Improvement) Systems -Reduces Material cost and to a lesser degree Labor costs Vendor/JIT (Just in Time [Inventory]) - Reduces Material costs and Administrative overhead QIT (Quality Initiative Training) - Reduces Labor costs Channel Support Systems Increases the effectiveness of the Sales Budget, and therefore demand Concurrent Engineering - Reduces R&D cycle time, the time needed to move products on the Perceptual Map and to change MTBF specifications. Continuous Process Improvement A process is a series of progressive and interdependent steps by which an end is attained. Continuous Process Improvement (CPI) is a strategic approach for developing a culture of continuous improvement in the areas of: reliability process cycle times costs in terms of less total resource consumption quality, and productivity. Deployed effectively, it increases quality and productivity, while reducing waste and cycle time. Just in Time Inventory Just-in-Time inventory system is designed to ensure that materials or supplies arrive at a facility just when they are needed so that storage and holding costs are minimized. The Just-in-Time system requires considerable cooperation between the supplier and the customer. The customer must specify what will be needed, when, and in what amounts. The supplier must be sure that the right supplies arrive at the agreed-on time and location. Quality Initiative Training Leaders of quality initiatives (project managers, managers, and senior leaders) develop useful and relevant knowledge and skills to ensure that company resources and efforts are utilized in the most effective manner. Leaders gain useful and skill based learning in these core quality leadership areas: Leading Teams Through Quality Initiatives Quality Philosophies and Approaches and Lessons Learned at Other Firms Customer Needs and Expectations Quality Improvement Management Systems Ethical Decision Making Channel Support Systems Support system to facilitate information sharing that increases productivity and profitability, untangling the web that once blocked the transfer of information. Predictive modeling. Determine how to market the right product to the right person at the right price and the right time. Customer, product and business line profitability. Identify the customer, product, organization and business line profitability bottom line. Product development and creation. Determine what products will sell; define the distinctive product characteristics and pricing. Target marketing. Sell the right product to the right person at the right time at the appropriate return. Sales execution and tracking. Collect information pertaining to who sells what product to whom, when and where. Concurrent Engineering Concurrent engineering is a business strategy replaces the traditional product development process with one in which tasks are done in parallel there is an early consideration for every aspect of a product's development process. Concurrent engineering provides a collaborative, cooperative, collective and simultaneous engineering working environment. The concurrent engineering approach is based on five key elements: a process a multidisciplinary team an integrated design model a facility a software infrastructure TQM Initiatives These initiatives improve product quality while reducing the time and resources required to design, manufacture, warehouse and ship products. Benchmarking - Reduces Administrative overhead Quality Function Deployment Effort - Reduces R&D cycle time and enhances the effectiveness of the Promo and Sales Budgets CCE (Concurrent Engineering)/6 Sigma Training - Reduces Material costs and Labor costs. GEMI TQEM Sustainability Initiatives - Reduces Material costs and Labor costs. Benchmarking A process in which organizations evaluate various aspects of their processes in relation to best practice, usually within their own sector. This allows organizations to develop plans on how to adopt such best practice, usually with the aim of increasing some aspect of performance. Benchmarking may be a one-off event, but is often treated as a continuous process in which organizations continually seek to challenge their practices. Benchmarking Procedure Identify your problem areas Identify other industries that have similar Identify organizations that are leaders in these areas Survey companies for measures and Visit the "best practice" companies to identify leading edge practices Implement new and improved business practices Quality Function Deployment Effort Flexible and comprehensive group decision making technique used in product or service development, brand marketing, and product management. QFD transforms customer needs into engineering characteristics of a product or service, prioritizing each product/service characteristic while simultaneously setting development targets for product or service development. QFD can strongly help an organization focus on the critical characteristics of a new or existing product or service from the separate viewpoints of the customer market segments, company, or technology-development needs. Six Sigma Training Six Sigma is a management technique that aims to develop and deliver near perfect products and services. "Six Sigma" refers to statistical constructs that measure how far a given process deviates from perfection. Processes are designed from the perspective of the customer and are enabled by a commitment to thinking in terms of processes across the organization. Metrics such as performance, reliability, price, on-time delivery, service and accuracy provide the targets.