White Paper Tool Shop Optimization: David Lindemann

advertisement

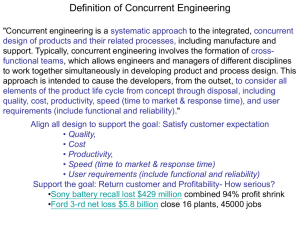

White Paper Tool Shop Optimization: Concurrent Engineering for Today’s Tool Shop David Lindemann Sr. Application Engineer Cimatron Technologies, Inc. Concurrent Engineering for Today’s Tool Shop Why Concurrent Engineering? One of the most pressing challenges faced by tool shops today is the need to shorten delivery times. As customers are vying to cut their own lead times from design to production, the pressure on toolmakers to deliver tools faster than ever continues to grow, even as die and molds are getting increasingly complex. Applying Concurrent Engineering principles and work processes can help tool shops get more tasks accomplished at any given time period, shrinking the overall lead time required to complete a project. Moreover, the by-products of Concurrent Engineering—such as standardization and improved communication—can reduce the time and effort required to complete each task on its own, and can produce significant efficiencies when it comes to applying engineering changes. What Is Concurrent Engineering? “Concurrent Engineering is a management/operational approach which aims to improve product design, production, operation, and maintenance by developing environments in which personnel from all disciplines work together and share data throughout all phases of the product lifecycle.” (http://cedar.web.cern.ch/CEDAR/glossary.html) Applied specifically to the tool shop environment, Concurrent Engineering embodies the following principles: A well-designed workflow: Concurrent Engineering does not mean that everybody is doing everything at the same time. Rather, it requires a well thought-out workflow which enables different phases of the process to be performed at the earliest possible times without sacrificing the efficiency of each individual task. Synchronization: With multiple tasks being performed in parallel, the synchronization of information at all phases is crucial to maintaining the integrity of the final product. Adaptability: Change is built into the process, enabling all phases of design and manufacturing to adapt on the fly with engineering changes. © Cimatron Technology, Inc. 2006 Page 2 Concurrent Engineering for Today’s Tool Shop How Does It Work? Concurrent Engineering begins with the initial interaction with the customer—the job quotation. Quoting is the lifeline of the business. It is also the first time the part data is being handled at the shop. For a company practicing Concurrent Engineering, common design standards and manufacturing strategies are used throughout, starting with the quoting phase. For example, material shrinkage parameters, part rotation and tip positions, and what standard components are going to be used. Incorporating these standards and strategies into the quoting process will ensure the quote reflects how design and engineering will approach the job. Once the job is released, Concurrent Engineering can drastically shorten tool design time, as multiple design tasks can be performed simultaneously. For example, one designer may work on the cavity side while another works on the core side; or one designer can finalize ejection while another designs the manifold and hot drops; or one designer is finishing waterlines while another begins pulling electrodes. Manufacturing and assembly work can start while the design details are still being worked out, further compressing product delivery times. Concurrent Engineering: Keys to Success For a tool shop to implement a true Concurrent Engineering process that delivers tangible business benefits, a number of prerequisites have to be met: Mindset: You cannot keep doing the same thing and expect different results; adopting concurrent engineering practices requires letting go of existing conventions and work habits. Leadership: Getting everybody on board with a new way of doing things is best achieved with a top-down approach; management needs to lead the way not only with words, but by making the necessary investments to support the change. Education: You cannot expect people to just figure it out as they go; getting up-to-speed on new processes requires training and education. Platform: No process can be successfully implemented without the appropriate system to support it. © Cimatron Technology, Inc. 2006 Page 3 Concurrent Engineering for Today’s Tool Shop Concurrent Engineering Software Requirements The software systems used at the shop play a critical role in its ability to transform concurrent engineering from theory to practice. While some systems can greatly facilitate the Concurrent Engineering process, others may pose an obstacle. Probably the most important requirement for enabling Concurrent Engineering is a single system and database that can be used for every job from start to finish—from quoting to delivery and engineering changes. With a single software system used throughout the shop, the quote produced can be ensured to accurately reflect the actual design standards and manufacturing strategies that will be applied to the job. Using a single system for design and manufacturing not only saves time and eliminates potential translation errors, it also ensures that NC and assembly work can start as early as possible, providing these departments with direct access to the design data, including up-to-date drawings and bill of material. Last but not least, Concurrent Engineering and the integrated design and manufacturing system pay huge dividends when engineering changes take place. Any changes done in design are immediately reflected in the data available on the shop floor, and a good portion of the changes can be automated by recalculating NC operations and eliminating the need for time-consuming reprogramming. © Cimatron Technology, Inc. 2006 Page 4 Concurrent Engineering for Today’s Tool Shop Getting Started: Implementation Roadmap Getting your tool shop to practice Concurrent Engineering is not something you can do overnight. It is also not something you can do without the proper preparation and commitment. The following is an eight-step roadmap that can be used to guide you through this effort: 1. 2. 3. 4. 5. 6. 7. 8. Define your goals Get management buy-in Understand your current processes Design the new process Put the systems in place Get people trained Measure your progress Redefine goals and restart the process As you go through the process, you will learn new things, come up with new ideas, and aspire to become even “more concurrent.” While the process is iterative in nature, you don’t have to wait long to start benefiting from incremental changes implemented. The benefits are there for you to reap—it is up to you to make the most out of it! For more information, visit www.cimatrontech.com. © Cimatron Technology, Inc. 2006 Page 5