IE 550 Manufacturing Systems - Industrial and Systems Engineering

advertisement

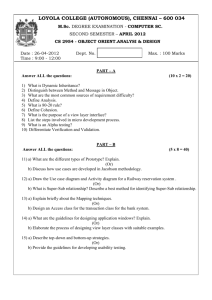

ISE 316 Manufacturing Engineering Introduction to Processes Richard A. Wysk Fall 2010 Office 414A Daniels Phone 515-1549 Email: rawysk@ncsu.edu Agenda • Policies - This is an engineering course, I do expect you to act like engineering students. Independent, diligent, creative,... • Engineering ethics • Policies and organization Grading Homework Quizes Labs Lab project Tests Participation TOTAL 10% 15% 10% 10% 50% 5% 100% Overview • What we will we be doing? – ISE316 is lots of fun. It may also be the most important class that you take. It is the materials that I most frequently use in my industry consulting. – Manufacturing engineering is a difficult topic that has hindered the development of CIM implementation. People do not understand how engineering systems fit together. This will be one of my foci for ISE316! Development activities • Labs have been developed and are intended to reinforce what is taught in class. • Active, collaborative learning will be the educational focus for the course. I am looking for feedback in this area. • Topically, the materials have been focused around a larger view of “Engineering – What role does Manufacturing play in it?” Introduction • What is a “Manufacturing system”? Interactions of many processes, products and design decisions made in the engineering of a product. – – – – Machine requirements planning Process planning Production planning Concurrent engineering Goal and Objective • GOAL -- Today’s manufacturing engineer needs to identify and locate the most efficient method to produce a product (inhouse or not) • OBJECTIVE -- reduce time to market, increase quality, reduce cost, and operate in a tight capital environment A Vision of Integrated Engineering Systems ENGINEERING -- the planning, designing, construction (manufacture), or management of machinery, roads, bridges, etc.. Traditional Engineering A Vision of Integrated Engineering Systems (cont.) INTEGRATE – 1. to make or become whole or complete. – 2. to bring parts together as a whole. – 3. to remove barriers imposing segregation. A Vision of Integrated Engineering Systems (cont.) INTEGRATED ENGINEERING – planning, designing, construction and management of a product. Engineering Product Engineering Process Engineering Production Engineering A Vision of Integrated Engineering Systems (cont.) INTEGRATION ENGINEERING – tools and techniques that can be used to assist in combining planning, design, construction and management of a product. A Vision of Manufacturing Systems (cont.) • INTEGRATED ENGINEERING – planning, designing, construction and management of a product. Concurrent or simultaneous engineering • Performing all business activities in unison • Making wise real-time economic decisions • Team concepts ISE316 Focus • ISE316 is intended to cover processing in the engineering wheel. • All spokes will be discussed. • Processes will be the concentration. Questions?!? Is everything perfectly clear?