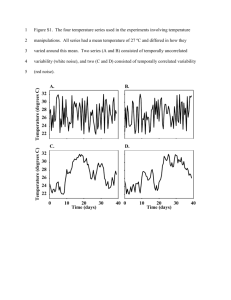

Variability!

advertisement

Variability Basics God does not play dice with the universe. ---Albert Einstein Stop telling God what to do. ---Niels Bohr 1 Variability Makes a Difference! Little’s Law: TH WIP CT Consequence: Same throughput can be attained with small WIP and cycle time or with large WIP and cycle time. Difference: Variability! 2 Variability Views Variability: • Any departure from uniformity • Random versus controllable variation Randomness: • Essential reality? • Artifact of incomplete knowledge? • Management implications: robustness is key 3 Probabilistic Intuition Uses of Intuition: • driving a car • throwing a ball • mastering the stock market First Moment Effects: • • • • Throughput increases with machine speed Throughput increases with availability Inventory increases with lot size Our intuition is good for first moments 4 Probabilistic Intuition (cont.) Second Moment Effects: • Which is more variable -- processing times of parts or batches? • Which are more disruptive -- long,infrequent failures or short frequent ones? • Our intuition is less secure for second moments • Misinterpretation -- e.g., regression to the mean 5 Variability Definition: Variability is anything that causes the system to depart from regular, predictable behavior. Sources of Variability: • • • • • • setups machine failures materials shortages yield loss rework operator unavailability • workpace variation • differential skill levels • engineering change orders • customer orders • product differentiation • material handling 6 Measuring Process Variability te mean process time of a job σ e standard deviation of process time ce e te coefficien t of variation , CV 7 Variability Classes in Factory Physics Low variability (LV) 0 Moderate variability (MV) 0.75 High variability (HV) 1.33 ce Effective Process Times: • actual process times are generally LV • effective process times include setups, failure outages, etc. • HV, LV, and MV are all possible in effective process times Relation to Performance Cases: For balanced systems • MV---Practical Worst Case • LV---between Best Case and Practical Worst Case • HV---between Practical Worst Case and Worst Case 8 Measuring Process Variability---Example Trial 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 te se ce ce2 Class Machine 1 22 25 23 26 24 28 21 30 24 28 27 25 24 23 22 25.1 2.5 0.1 0.01 LV Machine 2 5 6 5 35 7 45 6 6 5 4 7 50 6 6 5 13.2 15.9 1.2 1.4 MV Machine 3 5 6 5 35 7 45 6 6 5 4 7 500 6 6 5 43.2 127.0 2.9 8.6 HV 9 Natural Variability Definition: variability without explicitly analyzed cause Sources: • • • • operator pace material fluctuations product type (if not explicitly considered) product quality Observation: natural process variability is usually in the LV category. 10 Φυσική Μεταβλητότητα - Παράδειγμα • Μία εργασία απαιτεί μέσο όρο μία (1) ώρα (= 60 λεπτά) για να ολοκληρωθεί. • t 0 60 c 02 1 / 2 σ 02 1 / 2 60 2 1.800 • Εναλλακτικά, η εργασία μπορεί να διαιρεθεί σε δέκα (10) ξεχωριστές υποεργασίες που η κάθε μια απαιτεί μέσο όρο 6 λεπτά επεξεργασίας. c 02 1 / 2 σ 02 1 / 2 6 2 18 • Υποεργασία: t 0 6 2 c e2 180 / 60 2 0,05 • Εργασία: t e 10 6 60 σ e 10 18 180 • Ο συνολικός χρόνος επεξεργασίας των έχει μικρότερη μεταβλητότητα όταν εκτελείται σαν 10 υποεργασίες από ότι όταν εκτελείται σαν μία εργασία. (Εξήγηση: Στην πρώτη περίπτωση, για να τύχει ένας υπερβολικά μεγάλος χρόνος επεξεργασίας πρέπει να είμαστε άτυχοι μια φορά. Στην δεύτερη περίπτωση, για να τύχει ο ίδιος υπερβολικά μεγάλος χρόνος επεξεργασίας πρέπει να είμαστε άτυχοι 10 φορές. 11 11 Down Time---Mean Effects Definitions: t0 base process time σ 02 base process time variance r0 1 base capacity (rate, e.g., parts/hr) t0 m f mean time between failures mr mean time to repair 12 Down Time---Mean Effects (cont.) Availability: Fraction of time machine is up A mf m f mr Effective Processing Time and Rate: re Ar0 te t0 / A 13 Down Time---Variability Effects Effective Variability: te t0 / A 2 2 0 (mr r )(1 A)t0 2 σe Amr A 2 c 2 e e2 te2 c02 (1 cr2 ) A(1 A) mr m m c02 A(1 A) r cr2 A(1 A) r t0 t0 t0 Conclusions: • • • • Failures inflate mean, variance, and CV of effective process time Mean increases proportionally with 1/A SCV increases proportionally with mr For constant availability (A), long infrequent outages increase CV more than short frequent ones 14 Down Time---Example Data: Suppose a machine has • • • • • 15 min stroke (t0 = 15min) 3.35 min standard deviation (0 = 3.35min) 12.4 hour mean time to failure(mf = 12.6 60 = 744min) 4.133 hour repair time (mr = 4.133 60 = 248min) Unit CV of repair time (cr = 1.0) Natural Variability: c0 3.35 0.05 (very low variability) 15 15 Down Time---Example (cont.) Effective Variability: A mf m f mr 744 0.75 744 248 te t0 / A 15 / 0.75 20 min ce2 c02 (1 cr2 ) A(1 A) mr 248 (0.05) 2 (1 1)0.75(1 0.75) 6.25 t0 15 ce 2.5 (high variability!) Effect of Reducing MTTR: Suppose we can do frequent PM which causes mf = 1.9 hrs (= 114min), mr = 0.633 hrs (= 38min). A mf m f mr 114 0.75 114 38 ce2 c02 (1 cr2 ) A(1 A) mr 38 (0.05) 2 (1 1)0.75(1 0.75) 1.0 t0 15 ce 1.0 (medium variability) 16 Setups--Mean and Variability Effects Analysis: N s average no. jobs between setups t s average setup duration s std. dev. of setup time s cs ts te t0 ts Ns σ 2 e c 2 e 2 0 s2 Ns Ns 1 2 ts 2 Ns e2 te2 17 Setups--Mean and Variability Effects (cont.) Observations: • Setups increase mean and variance of processing times. • Variability reduction is one benefit of flexible machines. • However, the interaction is complex. 18 Setup--Example Data: • Fast, inflexible machine--2 hr setup every 10 jobs t0 1 hr N s 10 jobs/setup t s 2 hrs te t0 t s / N s 1 2 / 10 1.2 hrs re 1 / te 1 /(1 2 / 10) 0.8333 jobs/hr • Slower,flexible machine--no setups t0 1.2 hrs re 1 / t0 1 / 1.2 0.833 jobs/hr Traditional Analysis: No difference! 19 Setup--Example (cont.) Factory Physics Approach: Compare mean and variance • Fast,inflexible machine--2 hr setup every 10 jobs t0 1 hr c02 0.0625 N s 10 jobs/setup t s 2 hrs cs2 0.0625 te t0 t s / N s 1 2 / 10 1.2 hrs re 1 / te 1 /(1 2 / 10) 0.8333 jobs/hr cs2 N s 1 0.4475 σ t 2 Ns Ns ce2 0.31 2 e 2 0 2 s 20 Setup--Example (cont.) • Slower, flexible machine--no setups t0 1.2 hrs c02 0.25 re 1 / t0 1 / 1.2 0.833 jobs/hr ce2 c02 0.25 Conclusion: flexibility reduces variability. 21 Setup--Example (cont.) New Machine: Consider a third machine same as previous machine with setups, but with shorter,more frequent setups N s 5 jobs/setup t s 1 hr Analysis: re 1 / te 1 /(1 1 / 5) 0.833 jobs/hr cs2 N s 1 0.2350 σ t 2 Ns Ns ce2 0.16 2 e 2 0 2 s Conclusion: Shorter, more frequent setups induce less variability. 22 Other Process Variability Inflators Sources: • • • • • operator unavailability recycle batching material unavailability et cetera, et cetera, et cetera Effects: • inflate te • inflate ce2 Consequences: effective process variability can be LV, MV,or HV. 23 Illustrating Flow Variability Low variability arrivals t High variability arrivals t 24 Measuring Flow Variability t a mean time between arrivals ra 1 arrival rate ta σ a standard deviation of time between arrivals ca a ta coefficien t of variation of interarriv al times 25 Propagation of Variability cd2(i) ca2(i+1) i i+1 Single Machine Station: cd2 u 2ce2 (1 u 2 )ca2 where u is the station utilization given by u = rate Multi-Machine Station: u2 2 c 1 (1 u )(c 1) (ce 1) m 2 d 2 2 a where m is the number of (identical) machines and u ra te m 26 Propagation of Variability High Utilization Station High Process Var Low Flow Var High Flow Var Low Utilization Station High Process Var Low Flow Var Low Flow Var 27 Propagation of Variability High Utilization Station Low Process Var High Flow Var Low Flow Var Low Utilization Station Low Process Var High Flow Var High Flow Var 28 Variability Interactions Importance of Queueing: • manufacturing plants are queueing networks • queueing and waiting time comprise majority of cycle time System Characteristics: • • • • • • • • Arrival process Service process Number of servers Maximum queue size (blocking) Service discipline (FCFS, LCFS, EDD, SPT, etc.) Balking Routing Many more 29 Kendall's Classification A/B/C A: arrival process B: service process C: number of machines M: exponential (Markovian) distribution G: completely general distribution D: constant (deterministic) distribution. 30 Queueing Parameters ra = the rate of arrivals in customers (jobs) per unit time (ta = 1/ra = the average time between arrivals). ca = the CV of inter-arrival times. m = the number of machines. re = the rate of the station in jobs per unit time = m/te. Note: a station can be described with 5 parameters. ce = the CV of effective process times. u = utilization of station = ra/re. 31 Queueing Measures Measures: CTq = the expected waiting time spent in queue. CT = the expected time spent at the process center, i.e., queue time plus process time. WIP = the average WIP level (in jobs) at the station. WIPq = the expected WIP (in jobs) in queue. Relationships: CT = CTq + te WIP = ra CT WIPq = ra CTq Result: If we know CTq, we can compute WIP, WIPq, CT. 32 The G/G/1 Queue Formula: CTq V U t ca2 ce2 u te 2 1 u Observations: • Separate terms for variability, utilization, process time. • CTq (and other measures) increase with ca2 and ce2 • Flow variability, process variability, or both can combine to inflate queue time. • Variance causes congestion! 33 Variability and Cycle Time Relationships Flow Variabilit y cd2 (1 u 2 )ca2 u 2 ce2 u ra te te , ce2 ra , ca2 ra , cd2 Queue Time Process ca2 ce2 u CTq te 2 1 u Time te 34 The G/G/m Queue Analysis: CTq V U t ca2 ce2 u 2( m1) 1 te 2 m(1 u ) Observations: • Extremely general. • Fast and accurate. • Easily implemented in a spreadsheet (or packages like MPX). 35 Effects of Blocking VUT Equation: • characterizes stations with infinite space for queueing • useful for seeing what will happen to WIP, CT without restrictions But real world systems often constrain WIP: • physical constraints (e.g., space or spoilage) • logical constraints (e.g., kanbans) Blocking Models: • estimate WIP and TH for given set of rates, buffer sizes • much more complex than non-blocking (open) models, often require simulation to evaluate realistic systems 36 Blocking Example te(1)=21 te(2)=20 B=2 u t e (2) / t e (1) 20 / 21 0.9524 WIP ( M / M / 1) u 20 jobs 1 u M/M/1/b system has less WIP and less TH than M/M/1 system TH ( M / M / 1) ra 1 / t e (1) 1 / 21 0.0476 job/min 1-u b 1 0.9524 4 1 TH(M/M/ 1/b) r 0.039 job/min b 1 a 5 1-u 1 0.9524 21 18% less TH u (b 1)u b 1 5(0.9524 5 ) WIP ( M / M / 1 / b) 20 1.8954 jobs 90% less WIP b 1 5 1 u 1 u 1 0.9524 37 Attacking Variability General Strategies: • • • • look for long queues (Little's law) focus on high utilization resources consider both flow and process variability ask “why” five times Specific Targets: • • • • • equipment failures setups rework operator pacing anything that prevents regular arrivals and process times 38 Basic Variability Takeaways Variability Measures: • CV of effective process times • CV of interarrival times Components of Process Variability • • • • failures setups many others - deflate capacity and inflate variability long infrequent disruptions worse than short frequent ones Consequences of Variability: • variability causes congestion (i.e., WIP/CT inflation) • variability propogates • variability and utilization interact 39