Chapter 5: Notes

advertisement

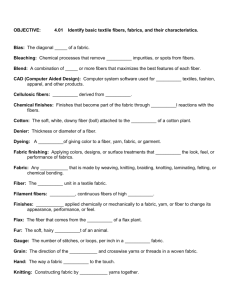

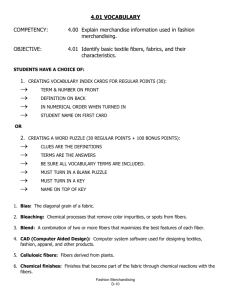

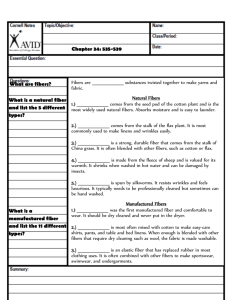

Textile Fiber and Fabric Production Fibers The conversion process ________________________________ refers to any material that can be made into fabric by any method o Textile Industry covers the entire apparel industry: production and marketing from raw material to the retail store. Fibers _______________________________________ Fabrics _______________________________________ Production and Marketing Chain [insert chain] Fibers Hair-like materials which form the ________________ elements of fabrics and other textiles All fiber producers must fill consumer needs o _________________________, moisture regain, elasticity, _________________, or crimp Classified as o ________________________________________ fibers o ________________________________________ fibers Natural Fiber Production Natural Fiber Categories Natural Fibers o Plants – _________________________________ Cotton Flax o Animals – ________________________________ Wools Silk Cotton World’s major fiber o ______________________________ is leading country; US is second o Cotton Belt: 17 ___________________________ states Vegetable fiber o Grows best in _________________________________ and subtropical climates Fiber grows in __________________ (green pods) o Once ripe and open - ready to be picked Manufacturing o Based on production system used and quality of ______________ desired o ___________________________: an operation that separates the fiber from the seed. Cotton Production Process Grows __________________________________________ Ginned o Separating the fiber from the seed ________________________________________ Carded (straightening the fibers) Combed o Removes short fibers, resulting in a smooth, uniform yarn Quality Factors Quality determines end use and price o ______________________________ o Maturity o Strength o ________________________ o Fineness Why cotton? Washable ________________________________________ o Wrinkle-resistant properties have been added Absorbent o Absorbs ______________________________ easily o Absorbs _____________________________, which makes you feel cool in hot, humid weather Can be light or heavy weight o Light and sheer (_______________________ and batiste) o Heavy and thick (corduroy, ___________________________, and chenille) o Strong and sturdy (_______________________) Flax Flax is made from the fibrous material in the ______________ of the flax plant. o Fiber is flax and the fabric is _________________________ Linen is the ______________________ known textile o Dates back to the stone age Stem of plant Length of fiber affects _________________________ ______% is grown in Russia o ___________________________ is the largest producer in the Western world. France and Belgium grow the best flax Cool summer clothing Flax processes ______________________________ Removal of adhesive substances and flax seeds that bind fibers together Breaking ______________________________ Fibers are separated from the outer bark and woody inner core of the stem _______________________________ /combing Ramie Ramie is a __________________________ fiber similar to flax o Grows best in subtropical climate Stronger than ________________ Imported from India, China, and the Philippines Smooth, lustrous appearance __________% ramie very difficult to spin o Brittle, often mixed with cotton to soften Wool _____________________ and renewable Resistant to wrinkling resource Thermal properties means warmth Absorbs up to 30% of weight in moisture Absorbs dye easily Returns to natural position after stretching Other fibers classified in the wool family _________________________________ Specialty wools ______________________________ Llama Camel’s hair ____________________________ Cashmere Vicuna __________________________ Wool cleaning process Scoured ________________________________ Combed o Woolens o ______________________ Silk Only natural fiber considered a ________________________________________ filament __________________________ is secreted from head and wound around the silk worm to form a cocoon Silk is steeped and boiled in soap baths to remove sticky substance and allow unwinding Triangular and reflects light _____________________________________ properties o Cool in summer and warm in winter Drapes well Types of Silk ______________________________ silk _______________________________ silk Wild or Tussah silk Schappe and bourette silks High-Tech Natural Fibers ________________________________ Silk o To capture strength of spider filaments for use in fabrics o Nexia Biotechnologies (Montreal, Canada) ________________________________ Fiber o A protein found in cows milk o Toyobo of Japan The following are in the experimental stages of development today: o Fibers from the sasawashi leaf, lenpur, __________________________________, and soybean Man-Made Fibers The Industry of Man-Made Fibers Dominated by large ____________________________________________ companies Industry requires mass production for purposes of efficiency Strong competition from ______________________________ Requires marketing of fiber product to consumers Blended with __________________________ fibers to achieve final product with positive characteristics of both fibers Man-Made Fiber Production Extruded from a ______________________________ solution of cellulose (purified ______________ pulp) or from chemical raw material o Then converted to a liquid state Raw materials are converted into ________________________, chips, _________________________, or pellets o Then dissolved in a solvent, melted with heat, or ________________________________ converted into a syrupy liquid and pumped through tiny holes of a spinneret _______________________________- the process of extrusion and hardening Man-Made Fibers Origins as replacement for expensive fibers (silk) Two types: o ________________________________ o Synthetic The MM Cellulosic fibers Rayon ______________________________________ Triacetate Rayon Sourced from wood pulp, cotton linters, ___________________________________________ matter dissolved Formed into fibers (process discussed later) Expensive to produce to environmental standards, limited worldwide production Led to development of _________________________________ Synthetic Fibers Also known as ____________________________________ fibers o ____________________________ o ______________________________ o Polyester o Polypropylene o Acrylic Nylon Strong ____________________________________ _____________________________________ Colorfast Flexible Polyester Most popular ______________________________________ __________________________ resistant Forms Easy care o Filament Often blended with o _____________________________ natural o Tow- short or broken fiber Acrylic High bulk-to-weight ratio Provides _________________________ ___________________________, fleece active wear, _____________________, coats, and fake furs Spandex Unequaled elasticity Does not ____________________________________ Usually blended in amounts of __________________________% Swimwear, hosiery, activewear High-Tech Man-Made Fibers Companies such as ______________________________________, Nomex, and Zylon o Strong of have high-temperature resistance o For use in the ______________________________________, firefighters, outdoor recreation and apparel New generation of synthetic fibers based on __________________________________________ and biodegradable materials instead of oil _________________ (polyactic acid) o Generic classification for _______________-based polymer o Cross between natural and man-made fiber Generic and Brand Identification US Federal Trade Commission assigns all new fibers a _____________________________ name Brand Name or ______________________________________ is an identifiable symbol The Textile Fibers Products Identification Act o All textile products must follow the law o In general, Use of generic fiber name In __________________________________ descending order __________________________________ are specialty fibers for special occasions Textile Yarn and Fabric Producers Textile Mills Mills are the producers of ________________________ May sell _________________________ (pronounced gray) goods to converters to be finished or produce both Small mills specialize in one fabric _____________________________________ Mills o Growth of firms forward or backward into the production or marketing chain Mills increase purchasing of the latest technology to offset the low ______________ cost advantage of importing Most US mills are suited to ____________________-volume production o In recent years due to competition from imports, many have begun to do small runs and more design changes Converters Only do _____________________________ conversion stages of production Numbers are declining Fewer converters exist due to importing of May ______________________ outside USA goods Source- finding the best quality goods at the Large companies do their ________ best price Yarn Production Filament Yarn Processing Filament Yarn Processing o _________________ Filament: twisted in a specialized silk spinning process o ___________________________ Filament: textured to provide bulk, loft, or elasticity ____________________________ is a process used on filament yarn to change the shape or characteristic into some form of crimp, curl, or coil Spinning Staple Fibers __________________________ Fibers o Cotton, flax, wood o Each fiber has its own ___________________________________________ system o Gives them strength to withstand the spinning process ______________________________________ Fibers o Cut into staple and spun on the same conventional spinning system used for cotton or on a new high-speed system to make yarn Fabric Production Fabric A cloth or material made from yarns Most popular o Wovens o ____________________________ o _______________________________ o Laminating o Bonding Weaving Interlacing of warp and ___________________ (filling) yarns o __________________________ is a process which yarns are wound onto a beam Warp yarns run _______________________________________, parallel to selvage (the edge of the fabric) Weft yarns are filling yarns and run perpendicular to selvage Loom speed and weave complexity are inversely related Warp yarns separate alternately (called ________________________________) to allow the filling yarns to interlace with them as they pass through the warp. Plain weaves One warp over one weft Most _____________________________________ Easy to manufacture Twill weaves _______________________ passes over a number of warp yarns Repetition shifts each weft row _____________________________________ Diagonal weave created Denim most popular Satin Weave One warp over a number of warp yarns Floats create ________________________________, luster Floats susceptible to damage Creating Patterns in Wovens Yarn-dye Patterns: o Distinguished differently from prints because the patterns appear on __________________ sides of the fabric Plaids, stripes and checks May also be produced by reversing the direction of the weave in certain areas or in alternate rows (__________________________________________) Variations of the 3 basic weaves are called ___________________________________ weaves __________________________________: o Cam, dobby, or Jacquard looms Knits __________________________ continuous yarn or combination of yarns Loops drawn through other loops Stretch depends upon _________________________, yarn construction, and knit production _________________________= number of needles per inch, the more needles the finer and closer knit the loops o ____________-cut machine has 10 needles per inch o 5-cut machine with 5 needles per inch is the most common Warp and Weft knitting are the ______ basic methods of _____________________________ fabric Weft Knitting Loops run __________________________________________ across width of fabric o Made on either a flatbed or circular machine ________________________________ machines produce single or double knits Generally more stretch ____________________________________ most popular Variations on Jersey Knit Purl-knit: reverse side of jersey; sweater knits __________________-knit: distinctive lengthwise rib on both sides of the fabric for added stretch Interlock: looks like jersey on both sides of the fabric Knit and welt: front and back beds of the knitting machines to create a welt ___________________ Jacquard: pattern on the face side Full Jacquard: full pattern on the face side, simple pattern on the back __________________________________: include tuck stitches, miss stitches, and pointelles Nonwoven Fabrics Nonwoven (__________________________________) fabrics are made by bonding or interlocking fibers, filaments, or yarns into a web or sheet by o Mechanical (pressure, needle punch, or needle tufting), o _____________________________ o Thermal (heat) o _______________________________ o Solvent Examples include nonwoven interfacings and nonwoven felt Production Centers ______________________ produces the most woven woolen apparel fabrics o Italy is next Hong Kong produces the most woolen knitwear (varies year to year) o _________________________________ o China o Italy Better ________________________________ come from Italy and Switzerland The US produces more _______________________________ than any other country o Largest cotton producer is ________________, followed by eastern Europe, India and then the US __________________________- Italy o Belgium o Northern Ireland o France, China and Poland Dyeing Dyeing Most lustrous and most _________________________________ to least (follows the production process) o Producer colored-dyed in chemical solution o ________________________ dyed-in raw fiber form o Yarn dying o Piece dying-fabric o ____________________________ dying o Also: cross dyeing Printing Printing Wet Printing o Engraved roller printing o ___________________________ printing Flatbed Screen Printing Rotary Screen Printing Dry printing o _____________________________________________/Paper printing Digital Printing Finishing Finishing Processes used to enhance the fabric o ____________________________________ o Appearance o __________________________________________ Physical means Chemical means Physical Means ______________________________________ Shearing Heat setting ____________________________/sueding Napping Shrink control ________________________ repellency Chemical methods Caustic reduction ______________________________________ Durable press ______________________________________ Other Finishes Flame retardant Mildew resistance ____________________________ light ________________________ resistance resistance Stain resistance Fade resistance Eco-Friendly Fibers Environmental Concerns New emphasis on _______________________________________ measures New standards for production _____________________________________ of fibers R&D activities ____________________________________ passed to consumers Countries vary in requirements