Fabrics

advertisement

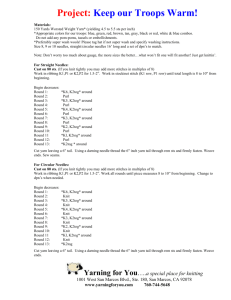

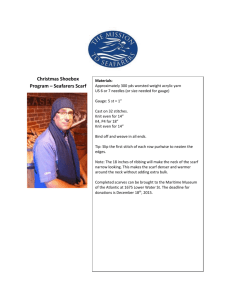

Fabrics Apparel 2 – obj. 1.02 Fabric Construction: Weaving and Knitting Woven Fabrics Interlacing 2 sets of yarns at right angles to each other Plain Weave Simplest of all weaves Most common Over, under; over, under **broadcloth, gingham, poplin muslin, and many others Twill Weave Diagonal weave **denim, gabardine **firm, heavy weave Satin Weave Shiny, reflects light Smooth and slippery Frays a lot **lustrous appearance Leno Weave Pairs of threads crossed over Looks “open” Fruit bags, mosquito netting Pile Weave Raised surface Loopy or furry Velvet Corduroy Knits – one yarn Warp – several yarns Purl – looks the same on both sides Weft Purl Knit Warp Knit Weft Knit Weft Knit** Uses one yarn **Single knit, ribbed and jersey Double Knit 2 yarns and 2 sets of needles Heavier and sturdier Doesn’t run or ravel Ribbed Knit Vertical ribs on front and back Neck and wrist bands on sweaters Jersey Knit Most common knit Plain, single knit T-shirts Very fine vertical wales on the right side Stable knit – lies flat Doesn’t run or ravel Lingerie, underwear Very fast to weave Tricot Knit Raschel Knit Uses extra yarn to create a pattern Non-woven Leather, lace, felt, disposable fabrics Heat, moisture Adhesive, bonding Yarns and layers Non-woven Interlocking fibers Don’t fray or ravel Flexible Might tear easily Felting Hot washing and drying wool Shrinks Soft and fluffy Interfacing Very light to very heavy and stiff Padding (quilting) Fusible or sew-in Fabric Finishes Special treatments applied to improve a fabric’s appearance, texture or performance “Gray Goods” Before any color or finish is added to the product. Bleaching Used to remove impurities in fabric to ensure a “true dye.” Yarn Dyed Yarns are dyed before weaving or knitting. Good for plaids, checks, and stripes. ** Fiber Dyed ** AKA “Stock Dyeing” Natural fibers dyed before spun into yarn Uniform color and good color fastness Piece Dyed** Fabric dyed after weaving or knitting Garment Dyed Fabric is cut and sewn Entire garment or item is dyed Printing Techniques Color is transferred to surface of fabric to form a pattern Roller Printing pres with circular rollers One for each color Rotary Screen Fast, inexpensive 3500 yards per hour Good for large designs** Texture and Performance Finishes Improves surface feel of fabric Improve comfort and wear ability Napping Raised, Fabric Fuzzy Sizing Extra body and weight Adds Starch Weighting A textured finish applied to make the garment stiffer and heavier looking than it is Advantage is to use a cheaper lighter weight fabric and make it appear stronger than it really is