Karmen – Corporate An Overview

advertisement

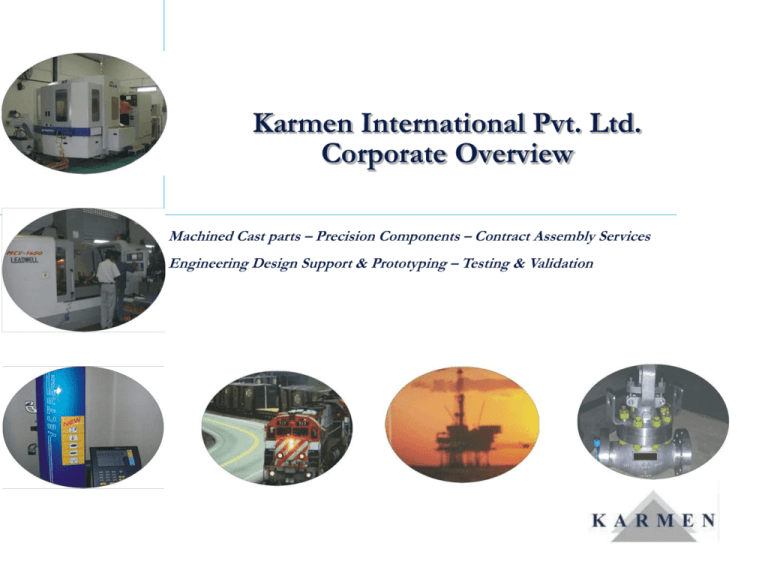

Karmen International Pvt. Ltd. Corporate Overview Machined Cast parts – Precision Components – Contract Assembly Services Engineering Design Support & Prototyping – Testing & Validation Presentation Outline Karmen Corporate Overview – – – – – – – – – – – – Background What we do Product Offerings Milestones 2000 - 15 Overview Manufacturing Facilities – Engineering Division with pictures Manufacturing Facilities – Castmetals Division with pictures What’s Unique about Karmen High 5 Health, Safety and Environment Plan for the future Why Karmen Background Past Experience & Expertise of the management group : – The Management team of Karmen had earlier founded and managed the most successful Export Oriented Indian Steel Foundry – Sivanandha Steels Ltd., up to 1999. – Set up in 1967 with technology from Demag, Germany and Cronite Foundry Group, UK, Sivanandha was the Top exporter of steel castings for 14 years from 1985 to 1999 and winner of the Govt. Of India’s Top Exporter Award for 10 years. – Supplied the Global Valve industry including Tyco Vanessa, Velan, Cameron, Crane Co., DeZurik, BHEL (Toa Valve Licensee) and earth moving equipment customers such as Caterpillar India and BEML (Komatsu Licensee). Management Background 1. Ramesh Venkatesan, CEO & Managing Director is a Production Engineer and holds a Master’s Degree from The University of Warwick, UK in “Engineering Business Management”. He has over 16 years experience in Steel foundry operations, global sourcing, precision engineering and International sales. 2. R.Marudachalam (RM), Executive Director is a Mechanical Engineer from Coimbatore Institute of Technology and has over 36 years of experience in valve casting technology. He has been closely involved the sourcing activity of global companies from India and has been trained at Cronite Foundry Group, UK. 3. Divya Biyani Venkatesan, Director and COO is an Economics graduate from the University of Madras and holds a Masters in Business Economics. She has been involved with Karmen as Operations Head since 2005. Prior to joining Karmen, she was National Sales Head for Thomson Reuters. 4. K.Subramanian (KS), Vice President – Management Processes holds a graduate degree in Physics and is one of the earliest ANST Level III certified professionals in India. During his career spanning over 40 years, he has built up a strong track record within the industry as an uncompromising Quality professional focused on NDT. He is also responsible for auditing and approving all Karmen suppliers. Karmen – What we do We are a Tier 1 manufacturer of high integrity machined cast parts and precision components to the valve, pump, and locomotive industries worldwide. • Machined Castings: Ferrous and Non Ferrous using sand and investment castings from less than 1 lbs to a maximum 10000 lbs. • Machined Forgings: Open die, closed die and ring rolled forgings fully machined upto 2000 lbs in a variety of alloy steel and stainless steels for the oil / gas / energy industries. • Precision Components: High precision machined components in a variety of materials grades including alloy steels, stainless steels, Inconel for the valve, locomotives, oil / gas and energy industries. Product offerings Industry Domains – Valves, Pumps, Earth Moving, Oil & Gas, Locomotive Machined Cast High Precision machining and value added services including hard facing and ground / lapped finish. Large casting capability added – 4000kg single piece. Parts Components Precision parts and components from bar stock and forgings. Full range of valve, pump, locomotive and precision parts for Oil & Gas applications. Materials WCB, LCB/LCC, CF8M, CF3M, CA6NM, CA15, Alloy Steels (WC6, WC9),SS Duplex , Super Duplex , Inconel, Monel, Aluminum, Aluminum Bronze, GCI and Ductile Iron. Contract Manufacturing Services Value Added Supply Chain Consolidation Complete assembly and testing services for pumps , valve and sub assemblies using machined cast , forged and fabricated components Integrating customer’s existing supplier base for higher value addition / inventory consolidation / Kanban / assembly in order to deliver better efficiencies Engineering Working with customers for design support services including Fab to cast conversion, cast to forge, improve manufacturability. Support Services Karmen Milestones 2000 - 15 Year 2000 - 01 Milestones Set up of facilities and commencement of business (Machining & Test – Unit 1) ISO Certification (Lloyds Registrar UK) Increased focus on Machined Castings “ready for assembly”. 2002 - 03 CNC Machining Capability added. Supply of “Valve kits” and precision components. ERP Implementation. 2004 - 05 Supply of fully assembled valves to customer drawings on exclusive basis. Lapping capability added. Wind Energy Division: 750 Kw Vestas Wind Mill set up. 2nd manufacturing site at Coimbatore- Focused factory with dedicated manufacturing cell for volume, repetitive products. 2006 - 07 Investment Program for expansion and up gradation of Unit I . Wind Energy Division: 2nd 750 Kw Vestas WEG set up. Karmen Cast metals Division Set up (Captive Steel Foundry) in Chennai. 2008 - 11 New Machining facility Unit III started production in Chennai. Supply of precision machined components for the oil / gas industry. Engineering Division – Unit IV under construction expected to be finished Q3 2015 to focus on precision machined components and assemblies. Expansion of facility including dedicated metrology area with CMM to be completed by April 2015 @ Unit II. Addition of 2012 – 15 new CNC turning capacity for large dia parts upto 1300 mm. Up gradation of facilities at Unit I including conversion of conventional to CNC. RT facility to be completed by Q1 2015 at Castmetals Division. Overview • Years in Business : 15 • Sales Turnover : – FY 2004-05 : US$ 2.7 Million – FY 2005-06 : US$ 5.0 Million – FY 2006-07 : US$ 7.9 Million – FY 2007-08: US$ 13.60 Million – FY 2008-09: US$ 15.00 Million – FY 2009-10: US$ 9.60 Million – FY 2010 – 11: US$ 11.00 Million – FY 2011 – 12: US$ 15.00 Million – FY 2012 – 13: US$ 19.00 Million – FY 2013 – 14: US$ 16.00 Million – FY 2014 – 15: US$ 19.00 Million • People Strength : 300 + • Manufacturing Facilities: – Engineering Division : 3 [Chennai & Coimbatore] – Castmetals Division : 1 [Chennai – Sipcot Oragadam] • No. of Customers : 24 • Geographies Covered : USA, Canada, UK, Germany, Australia, Japan, Indonesia Karmen Manufacturing Facilities Engineering Division: – Three machining facilities (Unit 1, 2 and 3) equipped with state of the art CNC horizontal and vertical machining centers, CNC VTL’s and other conventional equipment. – Every facility equipped with Faro / Romer Portable CMM Arm and other sophisticated measuring instruments. – Bridge type CMM (Zeiss) commissioned this month at Unit II – This division sources its input materials (castings, forgings, bar stock) from approved suppliers across the country. Key material grades supplied include Carbon Steels, Stainless, Alloy Steels, Ductile Iron, Aluminum, Al Br and exotics. Karmen Locations Unit-2 Corporate office & Unit-3 Unit -4 Under construction Castmetals Division Engineering Division Engineering Division Engineering Division – QA Facilities Zeiss CMM Faro CMM Arm Trimos Height Gauge Flatness check Air Gauge Magnetic Particle Inspections Kings Hardness Tester Portable Hardness Tester PMI Check Oil & Gas – BOP Parts (Cast and Forged/Components) 11”& 13” Ram Blank Made From : Forging Material Specification : AISI 4140 Upper Head Made From : Rolled Bar Material Specification : SS 17 – 4 PH, Condition H 1150 D 7”,11”& 13” Lock Screw Made From : Casting Material Specification : ASTM A 487/487M Insert Made From : Rolled Bar Material Specification : Inconel 718 11”& 13” Bonnet Made From : Casting Material Specification : ASTM A 487/487M 7” Gate Made From : Forgings Material Specification : SS 316 L Dual Plate Check Valve Machined Castings • Fully machined • Lapping / Grinding for plates and body seats • 2” to 48” upto 1500 class pressure rating • All materials including Al Br, exotic materials Valve Parts Machined sand & investment castings in ferrous & non ferrous material grades for valves Locomotive parts Forged – Ball Valve Body & End cap 3” & 4”Ball Valve Body Pressure Class: 1500 Make : Forging Material Specification : F 316 3” &4” End cap Pressure Class: 1500 Make : Forging Material Specification : F 316 Components Karmen Manufacturing Facilities Castmetals Division (Steel Foundry): • The modern steel foundry has been set up on a 5 Acre site near Chennai, India. • Moulding Line: Equipped with fully automatic IMF moulding line (Italy) including transfer cars, roll over, mould heating ovens, mould pushers, shakeout and mechanical reclamation system. • Sand System: Alkaline Phenolic Resin System (Alphaset). Flask size 1800 x 1400 x 550 mm. Max single piece weight of 1750 lbs. • Melting: The plant is equipped with 3000 / 2200 / 1100 lbs Inductotherm Furnace. • 4500 lbs Dual Trac Inductotherm Furnace under evaluation for Phase 2 of project for 330 tons per month capacity. Quality: • Fully equipped with latest spectrometer, mechanical lab, sand lab and complete range of NDT equipment all calibrated by TUV Nord. • ISO 9001 and PED certifications from TUV Nord and recently NORSOK approved • Latest LPG Fired and Electric Heat Treatment furnaces with automatic quenching arrangement. Capacity: • Current Capacity: 175 MT per month in Phase 1 • The capacity of the plant is expected to be 330 + tons after addition of 4500 lbs Dual Trac furnace in Phase 2 and will eventually increase to 500 tons in Phase 3. Karmen Castmetals - Facilities Certification & Approval Engineering Division Castmetals Division ASNT – ACCP Professional Level –III Certificate ASNT – NDT Level –III Certificate NORSOK Approval Customers Valve Industry : Transportation Industry: Oil & Gas Industry : Our Uniqueness • Our size – “ Small by Design” – Right size - Large enough to be reliable and small enough to be agile and highly responsive – Serviced by Karmen “A” Team • Excellent Track Record – – – – 100% referable clients Technically competent and experienced team with global exposure Trust, Credibility and Confidentiality aligned with corporate culture and strategy Financially Sound – willing and ready to make investments in new projects and opportunities to meet customer expectations. • “Goal Sharers” – instantly align to Customer’s goal • Non-commodity business is our niche Karmen HIGH 5 The Karmen HIGH 5 We are a performing team, delivering stretched goals and are motivated by measuring monthly our – 1.Delivery Performance (QOTD) 95% Quality On Time Delivery of line items 2.Customer Experience of our Product & Service (CEPS) Not more than 1 instance /quarter/customer 3.New Product Development (NPD) 90 days for machined sample after FAI 4.Responsiveness (RESP) 48 hours to respond internally & externally 5.First Time Right (FTR) 80% ( From Pattern to Final Inspection of Machined component) Why Karmen ? 1. Established and successful track record of forming and nurturing international alliances for over 30 + years with long term vision. 2. Proven capability in supply of machined valve castings and components to global standards backed by: • Strong manufacturing base including steel foundry. • Committed and dedicated team with hundreds of years of collective experience in valve supply chain, NDT & QA. 3. Recently established capability in manufacture of specialty valves to customer’s specifications including high end test requirements supplied direct to demanding customers. 4. Family owned and professionally managed by 3rd generation entrepreneurs. 5. Proximity to growing markets. 1 committed team backed by diverse, world-class, manufacturing capabilities focused on consistently delivering value to the customer. Thank You for your time For more information: Karmen International Pvt. Ltd. Corporate Office DP 48 & 51 Sidco Industrial Estate Thirumazhisai, Chennai – 602 107 India Tel: +91-44-26810750 Fax: +91-44-26810753 Email: Sales@karmengroup.com www.karmengroup.com