Soil & Crop Sciences, College Station, TX 77843

advertisement

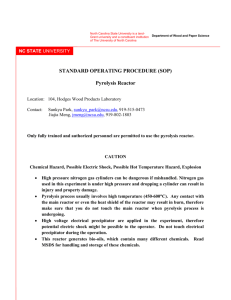

Nutrient Recovery from Pyrolysis Systems Jatara Wise1, Don Vietor1, Sergio Capareda2, Tony Provin1, Derek Husmoen1, Matthew Keough1, Clyde Munster2, & Akwasi Boateng3 (1) Soil & Crop Sciences, (2) Biological & Agricultural Engineering, College Station, TX, (3) USDA-ERRC,Wyndmoor, PA Results Abstract Bioenergy crops such as high-energy sorghum (HES), bioenergy rice, corn stover, and switchgrass can be thermochemically converted by pyrolysis to produce bio-oil, synthesis gas from non-condensable gases, and bio-char. The bio-char fraction can be recycled back to the production field to improve soil physical qualities and nutrient status. While various publications have demonstrated the beneficial effect of pyrolysis bio-char on soil physical properties, there has been limited data published on the recovery of mineral nutrients from pyrolysis co-products. This work quantified the recovery of nutrients (P, K, Ca, and Mg) in pyrolysis co-products from various feedstocks using two distinct reactors. Nutrient mass balances, on a biomass basis, were calculated to estimate nutrient recovery efficiencies. The results revealed P recoveries of 93% (fixed-bed reactor) and 58% (fluidized-bed reactor) for pyrolyzed HES. Recoveries for K, Ca, and Mg varied among feedstocks and between reactor types, suggesting nutrient recovery is dependant on both feedstock characteristics and reactor type. Materials and Methods 1) All feedstocks (corn stover, switchgrass, HES, and rice stover) were analyzed for nutrients using a sulfuric acid digestion. 2)Corn stover, rice stover and HES was pyrolyzed using laboratory scale fixed-bed reactor. • Bio-char was analyzed for nutrients using sulfuric acid digestion. • Bio-oil was ashed and prepared and analyzed for nutrients using Inductively Coupled Plasma Spectroscopy (ICP). • Non-condensable gas nutrient concentrations were analyzed using Inductively Coupled Plasma Spectroscopy (ICP). 3)Corn stover, switchgrass, HES was pyrolyzed using a state-of-the-art fluidized-bed, fast pyrolysis reactor. • Bio-char was analyzed for nutrients using sulfuric acid digestion. • Bio-oil was ashed and prepared and analyzed for nutrients using Inductively Coupled Plasma Spectroscopy (ICP). • Nutrient concentrations in non-condensable gases were not measured. • • • • Pyrolysis is the thermo-chemical decomposition of biomass at high temperatures in the absence of oxygen. Pyrolysis is a preferable renewable energy conversion process due to its short conversion time and small scale and mobile units could potentially reduce transport and handling costs. Species %P Std Dev %Mg Std Dev 30.25a 12.77 63.18a 26.62 63.30a 25.42 HES 93.63a 20.00 5.02c 1.75 68.89a 11.33 44.04b 13.12 Rice 52.22b 3.36 18.57b 0.96 45.63b 5.68 47.61b 3.17 † Numbers followed by the same letter within column were not statistically different (P=0.05). Table 2. Mean percent recovery of total feedstock P, K, Ca, and Mg in pyrolysis co-products from fluidized-bed, fast pyrolysis. Species %P Std Dev Corn 70.78a† 14.81 55.13a 3.25 HES Switch grass 58.55a 8.45 54.81a 35.54b 35.54 10.99b %K Std Dev % Ca Bio-char and bio-oil combined Std Dev %Mg Std Dev 68.47a 17.67 65.54a 7.1 8.04 60.15a 4.72 39.26b 3.55 1.72 44.58b 5.66 21.98c 0.97 Discussion and Conclusion • • Figure 1. Schematic diagram for laboratory scale fixed-bed reactor. Bio-char can be re-applied back to the production fields to: • Supply organic carbon for sequestration Replenish soil essential mineral nutrients The recovery of feedstock P from corn and rice stover and HES coproducts was relatively high and similar to previous reports for slow and fast pyrolysis of corn stover biomass (Husmoen, 2011, Mullen et al., 2009) (Table 1). However, the recovery of feedstock K from slow pyrolysis of corn stover, HES, and rice straw were seemingly low compared to previous reports of corn stover (Table 1) (Husmoen, 2011, Mullen et al., 2009, Schnell et al., 2011). P and K recoveries were also low when compared the fluidized-bed pyrolysis of fresh and stored swithcgrass biomass (Agblevor et al., 1995). Relatively low K recoveries in co-products of corn stover and HES for slow- compared to fast-pyrolysis indicated reactor type or conditions could affect nutrient recovery (Tables 1 and 2). Additionally, variation among species between reactor types indicated interactions between biomass source and reactor type could affect nutrient recovery and efficiencies of recycling through bio-char. Conclusion • Hypothesis and Objectives H0 : Variation of biomass species and reactor type have no effect on the percent recovery of mineral nutrients. The objectives of this study were to: Quantify the recovery of feedstock nutrients (P, K, Ca, and Mg) from pyrolysis co-products from various feedstocks using two distinct reactors. Evaluate if pyrolysis bio-char is suitable for recycling plant essential nutrients back to the soil. % Ca 20.54 • • Std Dev 50.09b† The crops analyzed in this study are high-energy sorghum (HES), switchgrass, corn stover, rice stover. Ha : There is some effect. %K Corn • • Std Dev Co-products combined It is believed that the majority of mineral nutrients reside in the bio-char (Coleman et al., 2010). • pyrolysis co-products from fixed-bed, slow pyrolysis. † Numbers followed by the same letter within column were not statistically different (P=0.05). Introduction • Table 1. Mean percent recovery of total feedstock P, K, Ca, and Mg in • • Recovery of feedstock nutrients varies amongst species, but species ranking differed among reactor type. Nutrient recoveries among combinations of feedstock source and reactor types differed among P, K, and Mg. Additional research is needed to evaluate factors contributing to recovery differences between nutrients and reactor types and feedstocks. Acknowledgements • Figure 2. Layout for fluidized-bed system (Boateng et al., 2007). • I would like to thank Mr. Bill Allen for his tireless assistance and advice. USDA National Needs Fellowship, Sloan Foundation, SunGrant (North Central Region), and Hispanic Leaders in Agriculture and the Environment (HLAE) for financial support. References • Please contact Jatara Wise (jwise@tamu.edu) for references.