Pyrolysis Reactor

advertisement

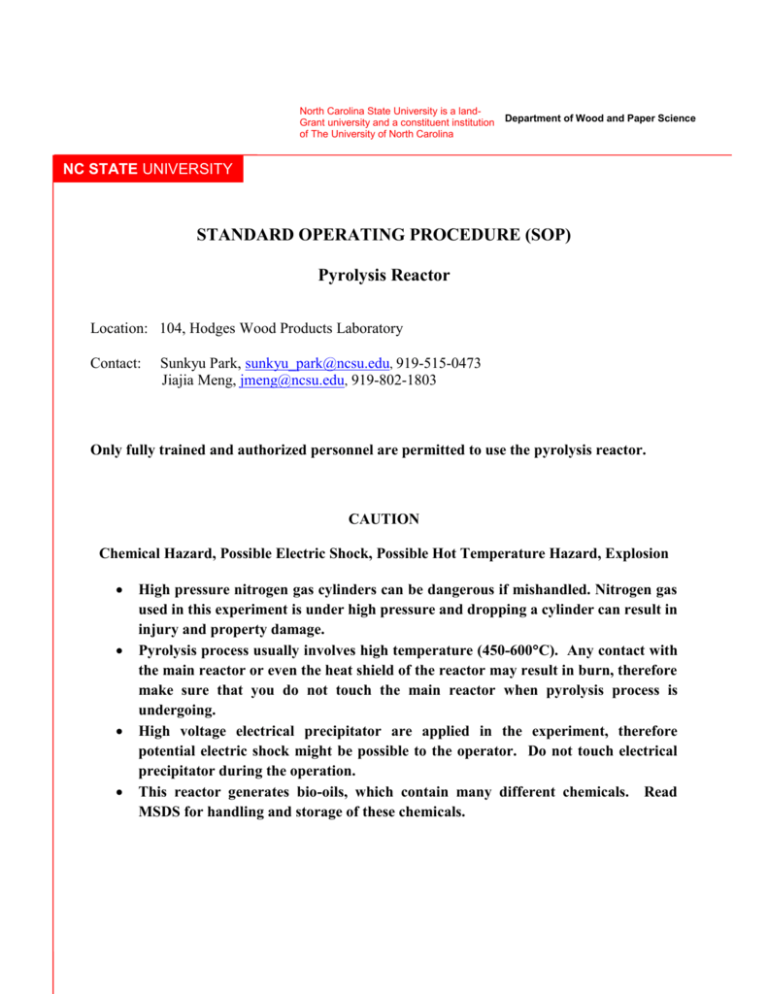

North Carolina State University is a landGrant university and a constituent institution of The University of North Carolina Department of Wood and Paper Science NC STATE UNIVERSITY STANDARD OPERATING PROCEDURE (SOP) Pyrolysis Reactor Location: 104, Hodges Wood Products Laboratory Contact: Sunkyu Park, sunkyu_park@ncsu.edu, 919-515-0473 Jiajia Meng, jmeng@ncsu.edu, 919-802-1803 Only fully trained and authorized personnel are permitted to use the pyrolysis reactor. CAUTION Chemical Hazard, Possible Electric Shock, Possible Hot Temperature Hazard, Explosion High pressure nitrogen gas cylinders can be dangerous if mishandled. Nitrogen gas used in this experiment is under high pressure and dropping a cylinder can result in injury and property damage. Pyrolysis process usually involves high temperature (450-600C). Any contact with the main reactor or even the heat shield of the reactor may result in burn, therefore make sure that you do not touch the main reactor when pyrolysis process is undergoing. High voltage electrical precipitator are applied in the experiment, therefore potential electric shock might be possible to the operator. Do not touch electrical precipitator during the operation. This reactor generates bio-oils, which contain many different chemicals. Read MSDS for handling and storage of these chemicals. Standard Operating Procedure 1) Wear protective glass. 2) Cover the reactor shield with aluminum foil so as to reduce the heat loss. 3) Check the linkage of the entire pyrolyzer. 4) Check nitrogen pressure on gauge. It should have enough volume to supply the whole process. 5) Open the nitrogen valve and adjust the speed of nitrogen flow for feeding system and reactor respectively. Check if there is any leakage from the whole reactor. 6) Power on the pyrolyzer. 7) Start the circulator providing cooling liquid for the condenser(s). 8) Initiate the heater and set the temperature to the designated one. Max temperature is 600C for this system. 9) Start the motor and feed biomass powder into the receiver when the temperature reached the desired one. The recommended speed for motor is 40 rpm/min and the recommended feeding speed is 200g/h. Recommended biomass particle size is between 40-60 mesh with less than 15% moisture content. 10) Initiate the precipitator and set the electricity currency and voltage to 10kV. 11) Keep feeding biomass at a constant speed and maintain the temperature of the reactor at the designated one. 12) Turn off the heater, motor and precipitator when your desired amount of bio-oil has been condensed. Do not leave any biomass particle in the motor. 13) Cool down the reactor and collect the bio-oil from the flask connected to first condenser and from the flask connected to the precipitator for further analysis. 14) Turn off the circulator and nitrogen gas. 15) Clean the flask, condenser and precipitator. 16) Clean the sample feeding system with high pressure air. 17) Change the sand in the reactor if necessary. 18) Install the liquid collecting system when flask, condenser and precipitator are dried.