PEM Yakıt Hücresi ve NTNU'daki Çalışmalar

advertisement

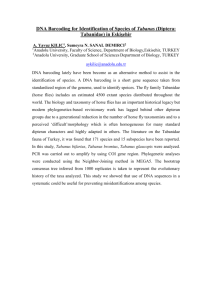

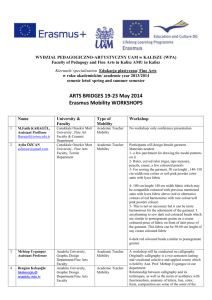

Anadolu Üniversitesi University Based Innovation on PEMFC in Turkey Assoc. Prof. Dr. Süleyman Kaytakoğlu Anadolu University Faculty of Engineering and Architecture Department of Chemical Engineering Eskişehir, Turkey February 26-28, 2007 GeT Univation! Anadolu Üniversitesi I. Part Presentation of Dept. of Chemical Engineering Anadolu Üniversitesi Anadolu University Department of Chemical Engineering GeT Univation! Anadolu Üniversitesi Education - Since 1970 MSc Programme - Since 1981 PhD Programme - Since 1984 BSc Programme GeT Univation! Anadolu Üniversitesi Academic Staff Professor Assoc. Professor Assist. Professor Research Assist. Technicians 4 1 8 10 2 GeT Univation! Anadolu Üniversitesi Research Statistics International Journal Articles National Journal Articles Conference Proceeding Articles 7 5 9 GeT Univation! Anadolu Üniversitesi Labs and Equipments • 5000 square meter closed area • 2 million € worth of equipment • One of the well equipped student and research laboratories in Turkey GeT Univation! Anadolu Üniversitesi Research Infrastructure at Department of Chemical Engineering Full Electrochemical System – Solartron Fuel Cell Test Facilities GC GC-MS Elemental Analyzer Atomic Absorption Analyzer HPLC Fuel Test Lab FTIR UV-VIS GeT Univation! Anadolu Üniversitesi Research Infrastructure at Faculty of Engineering and Architecture TEM SEMs (low vac. 0.6nm, EDX,WDX) AFM XRDs (Theta-Theta, up to 2000ºC, Rietveld) XRF TG-DTA/DSC BET FTIR ICP Mercury Porosimeter Rapid prototyping facilities Well equipped workshop GeT Univation! Anadolu Üniversitesi II. Part Presentation of University Based Innovation on PEMFC Anadolu Üniversitesi PEM Fuel Cell Anode H2 2H+ + 2e-, U0 =0 V Operating Temperature Power Output Applications Required Power Cathode ½ O2 + 2H+ + 2e- H2O, U0 = 1,229 V 20-80ºC Upto 250 kW Portable, Transport, Military, Space Cars(75 kW), Buses (250 kW) GeT Univation! Anadolu Üniversitesi Research Milestones H2 production studies began in 1997. PEMFC activities in Dept. of Chem. Eng. started in 2002. Since then, our PEMFC cell activities have made a peak due to collaborations with Juelich research institute, Germany. GeT Univation! Anadolu Üniversitesi Fuel Cell Market • 2000 $218 million • 2005 $2.4 billion (The Freedonia Group, Inc.) • 2009 $7 billion (Business Com. Company, Inc.) • 2020 $1.7 trillion (Price Waterhouse-Coopers) • 2030 750,000 jobs (U.S. Dept. of Energy) Anadolu Üniversitesi Barriers to fuel cell commercialization High cost of PEMFC components Material costs for a present-day fuel cell stack Material mass Material cost (US$/kW) Lack of(kg/kW) fueling infrastructure Membrane 0.025 120 Electrode 0.082 31.16 Catalyst affordable 0.016 hydrogen production 243.2 and storage Efficient, Bipolar plate 3.3 825 End plate 0.12 0.24 Plastic frame 0.105 0.105 Total 3.684 1219.705 Kwi Seong Jeong and Byeong Soo Oh Fuel economy and life-cycle cost analysis of a fuel cell hybrid vehicle Journal of Power Sources Volume 105, Issue 1 , 5 March 2002, Pages 58-65 GeT Univation! http://www.buchmann.ca/Article1-Page1.asp Energy Source Investment of equipment to generate 1kW Lifespan of equipment before major overhaul or replacement Cost of fuel per kWh Total Cost per kWh, incl. fuel, maintenance and equipment replacement. NiCd For portable use $7,000 based on 7.2V, 1000mAh at $50/pack 1500 h based on 1C discharge $0.15 electricity for charging $7.50 Gasoline Engine For mobile use $30 based on $3,000/100kW (134HP) 4000 h $0.10 $0.14 Diesel Engine For stationary use $40 based on $4,000/100kW (134HP) 5000 h $0.07 $0.10 Fuel Cell $3,000 – 7,500 $0.35 For portable use 2000 h $0.35 $1.85 – 4.10 For mobile use 4000 h $0.35 $1.10 – 2.25 For stationary use 40,000 h $0.35 $0.45 – 0.55 All inclusive 0.10 0.10 Electricity From electric grid All inclusive Anadolu Üniversitesi What are we doing for FCs? 1. Manufacture of Gas Diffusion Layer 2. MEA production by both conventional and sputter methods 3. Building up a FC test station upto 5 kW –hardware and software4. PEMFC stack manufacturing – 1 kW 5. Micro size -both active and passive- DMFC production GeT Univation! Anadolu Üniversitesi Manufacture of Gas Diffusion Layer Thickness : 300 μm Carbon content : 3-5 mg/cm2 PTFE content : 1-2 mg/cm2 GeT Univation! Anadolu Üniversitesi MEA Production Conventional (Pt loading range: 0.1-5 mg Pt/cm2) Sputtered (Pt loading range: 0.01-0.1 mg Pt/cm2) GeT Univation! Anadolu Üniversitesi Building up a FC Test Station GeT Univation! Anadolu Üniversitesi PEMFC Stack Manufacturing GeT Univation! Anadolu Üniversitesi DMFC Production GeT Univation! 1,2 400 4 barg E-TEK 350 PEM001 1 PEM002 300 250 0,6 200 150 Power Density, mW/cm 2 0,8 Potantial, V Anadolu Üniversitesi Results for Conventional MEA 0,4 100 0,2 50 0 0 0 200 400 600 800 1000 1200 Current Density, mA/cm2 GeT Univation! 1,2 400 E-TEK SP001 1 350 SP005 SP010 300 SP020 250 0,6 200 150 0,4 Power Density, mW/cm 2 0,8 Potential, V Anadolu Üniversitesi Results for Sputter Based MEA 100 0,2 50 0 0 200 400 600 800 1000 1200 0 1400 Current Density, mA/cm 2 GeT Univation! 35000 E-TEK SP005 30000 SP001 SP010 SP020 25000 mW/mg Pt Anadolu Üniversitesi Results for Sputter Based MEA 20000 15000 10000 5000 0 0 200 400 600 800 Current Density, mA/cm 1000 1200 1400 2 GeT Univation! Anadolu Üniversitesi SEM Image 120 s GeT Univation! Anadolu Üniversitesi ”The Europe of Knowledge 2020: A vision for university based research and innovation” Liege 25-28 April’04 • Interdisiplinary Approach • Relationship between Higher Education and Research • University – Industry Relationship • The effect of universities in the development of regional development • Mobility of Researchers including between University and Industry • Commercialisation of university based innovation GeT Univation! Anadolu Üniversitesi Research Collaborations •DAAD (Germany) •Jülich Research Center (Germany) •Technical University of Karlsruhe (Germany) •Solitem Group (Germany) •Louisiana State University (USA) •NTNU, SINTEF and IFE (Norway) •KTH (Sweden) •UNIDO-ICHET (Turkey) GeT Univation! Anadolu Üniversitesi Industrial Collaborations • Arıkan Machinery Industry GmbH • Demirdöküm DD Heating GmbH • Savronik Defense Industry GmbH GeT Univation! Anadolu Üniversitesi On Going Projects •Development of a 1 kW PEMFC stack •Maximization of Pt Utilization at PEMFC Electrodes using sputtering method •Optimization of MEA Components •Optimization of operating parameters of PEMFC •Design and Testing of DMFC •Design and Testing of Passive DMFC GeT Univation! Anadolu Üniversitesi Future Projects • Combined Heat and Power (CHP) System for household application • Transportation application of a PEMFC stack • Capture, storage and electrochemical reduction of CO2 to CO • High purity hydrogen production via steam reforming of natural gas •Membrane for High Temperature PEMFC applications •Non-Pt based electrocatalyst development for FCs GeT Univation! Anadolu Üniversitesi If you have a problem for which our expertise could be of use, we would like to become your partner - please do not hesitate to contact us! Contact Point Assoc. Prof. Dr. Süleyman Kaytakoğlu Anadolu University Dept. Of Chemical Engineering 26555 - Eskişehir/Turkey Phone: +90-222-3213550/Ext. 6306 Fax: +90-222-3239501 E-mail: skaytako@anadolu.edu.tr GeT Univation! Anadolu Üniversitesi Thank you for your attention GeT Univation!