High-Temperature Dilute-Acid Hydrolysis of Hazelnut Shells for

advertisement

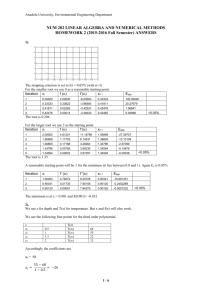

High-Temperature Dilute-Acid Hydrolysis of Hazelnut Shells for Xylose and Furfural Production Selin Üreya, Emir Zafer Hoşgün, Berrin Bozan, a Anadolu University, Engineering Faculty, Chemical Engineering Department, Eskisehir, Turkey; Tel. +90 222 3213350/6500 e-mail: surey@anadolu.edu.tr; ezhosgun@anadolu.edu.tr; bbozan@anadolu.edu.tr Lignocellulosic biomass is considered nowadays as an important renewable and sustainable resource that can be potentially used to provide biofuels or to produce chemicals. Dilute sulfuric acid pretreatment has proven to be a very effective in recovering most of the hemicellulose sugars from biomasses during pretreatment. In this study, the effect of dilute acid catalyzed, high temperature pretreatment of hazelnut shells at different temperatures and reaction times on the xylose and furfural yield were investigated. Pretreatment were performed in a high temperature-high pressure stainless steel reactor (Parr) with H2SO4 (1 %, v/v) at different temperatures (120, 160, and 200 oC) and for different operating times (1, 10, and 30 min). Solution was kept liquid under N2 atmosphere. At the end of the treatment, the treated slurry was collected and filtered using filter paper to separate the solid and liquid fractions for further analysis. Compositions of liquid products were analyzed by high-performance liquid chromatography (HPLC). In this study xylose production decreased with increasing temperature from 120 to 200 C, due to conversion of xylose to other substances (especially furfural). Maximum xylose production (12.02 mg/ml) was observed when hazelnut shells were hydrolyzed at 120 ◦C for 1 minutes duration time in 1 % sulphuric acid solution. Under these conditions, the contents of furfural, 5-hydroxymethylfurfural, acetic acid and glycerol were found as 0.29 mg/mL, 0.024 mg/mL, 2.21 mg/mL and 0.29 mg/mL respectively. Although, increasing temperature from 120 to 160 0C resulted in some positive effects on furfural production, the xylose production was decreased. Furfural production was maximized (2.88 mg/mL) at the 160 ◦C for 30 minutes duration time in 1 % sulphuric acid solution. 0 Topic 4. Biomass technologies and applications III:biofuels and future transportation energy This study was supported by Anadolu University Scientific Research Projects Commission under the grant no: 1502F080