water technology

Unit-1

Water technology

Unit-1 Water Technology

The process of removing all types of impurities from water of impurities from water and making fit for domestic (or) industrial purpose is called water technology.

Types of impurities in water:

The impurities present in water may be broadly classified into three types

(i)Physical impurities

(a) Suspended impurities

(b) Colloidal impurities

(ii) Chemical impurities

(a) Dissolved salts

(b)Dissolved gases

(iii) Bacterial impurities

Boiler feed water

The water fed into the boiler for the production of steam is called boiler feed water.

Requirements

Boiler feed water should be free from turbidity, oil, dissolved gases, alkali and hardness causing substances.

Hard water:

Which does not produce lather with soap solution, but produce white precipitate (scum) is called hard water.

2C

17

H

35

COONa +Ca

++

→ (C

17

H

35

COO)

2

Ca + 2Na +

Soft water: Which produce lather readily with soap solution is called soft water. Absence of Ca& Mg salts.

Types of hardness:

1.Temporary hardness

2.permanent hardness

Units of hardnss:

Parts per million(ppm)

It is defined as the no.of parts of CaCo

3 eqivalent hardness per 10

6 parts of water.

Milligram per litre(mg/lit)

It is defined as the no.of milligrams of CaCO

3 equivalent hardness per 1 litre of water.

Clarke’s degree (Cl)

It is defined as the no.of parts of CaCO

3 equivalent hardness per 10

5 parts of water.

French degree(Fr)

It is defined as the no.of parts of CaCO

3 equivalent hardness per 10

5 part of water.

1ppm=1mg/lit=0.1

0

Fr=0.07

0 cl

Alkalinity determination:

PRINCIPLE

Alkalinity in water is due to the presence of soluble hydroxides, bicarbonates and carbonates. Alkalinity can be determined by

Potentiometric methods

Using pH meter

Titrimetry using different indicators

Determination of various types and amounts of alkalinity is easily carried out by titration with standard HCl employing the indicators phenolphthalein and methyl orange independently or in succession.

The following reactions occur when different types of alkalinity are neutralized with acid.

OH - + H + H

2

O completed at pH 8.2-9.0 ----------- (1)

CO

3

2- + H

+

HCO

3

- -------------- (2)

HCO 3- + H + (H

2

CO

3

) H

2

O + CO

2

,

Completed at pH 4.2-5.5------------(3)

Neutralization (1) & (2) will be notified by phenolphthalein end-point while all the three will be accounted by methyl orange end-point.

Bicarbonate in equation (3) may be due to the existence of soluble free bicarbonate salts or bicarbonates resulting from half neutralization of soluble carbonates (eqn. (2)) Various steps to be followed:

A known volume of water sample is titrated against std. HCl using first phenolphthalein indicator till end-point (P) and the titration is continued without break using methyl orange indicator till the equivalence end-point (M).

From the magnitudes of the P & M, the nature of alkalinity can be arrived as follows:

(i) P = M => Presence of only OH -

(ii) 2P = M => Presence of only CO

32-

(iii) P =0, M#0 => Presence of only HCO

3-

(iv) 2P > M => Presence of OH & CO

32-

(v) 2P < M => Presence of HCO

3-

& CO

32-

(Mixture of OH & HCO

3

are not listed since they do not exist together and are considered equivalent to CO

32-

).

PROCEDURE

TITRATION – I

STANDARDISATION OF HCl

Exactly 20 ml of the given standard NaOH solution is pipetted out into a clean conical flask and 2 drops of phenolphthalein indicator is added.

The solution is titrated against the given HCl taken in the burette. The pink colour of the solution in the conical flask disappears at the endpoint. The titre value is noted down from the burette and the titration is repeated to get concordant value.

TITRATION – II

ESTIMATION OF ALKALINITY IN WATER SAMPLE

Exactly 20 ml of water sample is pipetted out into a clean conical flask.

Few drops of phenolphthalein indicator are added and titrated against the standardized HCl taken in the burette. The end-point is the disappearance of pink colour, which is noted as P. Into the same solution few drops of methyl orange indicator is added. The solution changes to yellow. The titration is continued further by adding same

HCl without break till the end-point is reached. The end point is the colour change from yellow to reddish orange. The titre value is noted as

M.

The experiment is repeated to get concordant values. From the magnitudes of P & M values, the type of alkalinity present in the water sample is inferred and the individual amounts are calculated and reported.

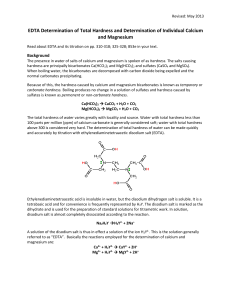

Estimation of hardness by EDTA method:

EDTA: Ethylene Diammine Tetra Acetic acid

(CH

2

COOH )

2

N-CH

2

-CH

2

-N(CH

2

COOH)

2

Principle:

Hardness causing ions (Ca 2+ ,Mg 2+ ) estimated by titrating the water sample against EDTA.

Indicator: eriochrome –black –T

Buffer soln: (NH

4

Cl-NH

4

OH): PH:8-10

*Ca 2+ ,Mg 2+ +EBT→*Ca,Mg EBT+ complex(wine red coloured weak complex)

*Ca ,Mg EBT+Complex +EDTA→*Ca Mg EDTD++EBT(Steel blue)

The estimation is based on the complexometric titration.

(i) Total hardness of water is estimated by titrating it against EDTA using EBT indicator.

EBT+ Mn + [EBT-M] (complex)

EBT-M (unstable complex) +EDTA [EDTA-M] (stable complex) +EBT

(Wine red) (Steel blue)

EBT indicator forms wine red coloured complex with hardness causing metal ions present in water. On addition of EDTA, metal ions preferably form complexes with EDTA and steel blue EBT indicator is set free.

Therefore change of colour from wine red to steel blue denotes the end point.

(iii) Temporary hardness is removed by boiling the water.

Ca (HCO

3

)2 CaCO

3

↓+ CO

2

+H

2

O

Mg (HCO

3

)

2

Mg(OH)

2

↓ + 2CO

2

The precipitate is filtered and the remaining permanent hardness is estimated using EDTA.

Pipette out 20ml of standard CaCl

2

into a 250ml conical flask. (Standard hard water is prepared by dissolving 1 g of calcium carbonate in one litre of distilled water) . Add 5ml of buffer solution and 3 drops of eriochrome black T indictor. Titrate the solution with EDTA from the burette until the colour changes from wine red to steel blue at the end point. Repeat the titration for concordant values. Let the titre value be

V1ml.

TITRATION – II

(ii) DETERMINATION OF TOTAL HARDNESS

Pipette out 20ml of sample hard water into a clean conical flask. Add

5ml of buffer solution and 4 -5 drop of eriochrome black T indicator.

Titrate the wine red coloured solution with EDTA from the burette until the colour steel blue appears at the end point. Repeat the titration for concordant values. Let the titre value be V2ml.

TITRATION – III

(iii)DETERMINATIONOF PERMANENT HARDNESS

Take 250ml of hard water sample in a 250ml beaker and boil gently for about 20 minutes. Cool, filter it into a 250ml standard flask and make the volume upto the mark. Take 20ml of this solution and proceed it in the same way as in titration (I). The volume of EDTA consumed

corresponds to the permanent hardness of the water sample. Let the titre value be V3ml. Temporary hardness is calculated by subtracting permanent hardness from total hardness.

Step 1- Arriving at standard equation,

1ml of Std CaCl

2

= 1 mg of CaCO

3

( given)

V1 ml of EDTA = 20 ml of Std. CaCl

2

1 ml of EDTA = (20 / V1) ml of Std. CaCl

2

Therefore, ml of EDTA = (20 / V1) mg of CaCO

3

(standard equation.)

Step 2.- Calculation of total hardness.

Volume of EDTA consumed (V

2

) =-------- ml

20ml of sample hard water = V

2

ml of EDTA

1000 ml of sample hard water =V

2

X(1000/20) ml of EDTA

As per standard equation,100ml of given hard water = V

2

X (1000/20) X

(20 / V

1

) mg of CaCO

3

=1000 x (V

2

/ V

1

) mg of CaCO

3

Therefore, total hardness = ----------ppm

Step 3.- Calculation of permanent hardness.

Volume of EDTA consumed (V3) =-------- ml

20ml of boiled water = V

3

ml of EDTA

1000 ml of boiled water =V

3

X (1000/20) ml of EDTA

As per standard equation,

1000ml of given hard water= V

3

X (1000/20) X (20 /V

1

) mg of CaCO

3

= 1000 x (V

3

/ V

1

) mg of CaCO

3

Therefore, permanent hardness = ----------ppm

Step 4 – Calculation of temporary hardness

Temporary hardness of the given sample of water =

Total hardness –Permanent hardness =ppm

Treatment of water for domestic supply:

Screening:

It is a process of removing the floating material like leaves, wood pieces, etc. from water.

Aeration:

The process of mixing water with air is known as aeration.

To remove gases like CO

2

, H

2

S

Sedimentation:

It is a process of removing suspended impurities by allowing the water to stand un disturbed for 2-6 hours in a big tank.

Coagulation:

In this method certain chemicals called coagulants, like alum,

Al

2

(SO

4

)

3

+6H

2

O→Al(OH)

3

↓+3H

2

SO

4

Filtration :

It is the process of removing bacteria, colour, taste, odour .Passing water through filter beds.

Sterilization (or)disinfection:

The process of destroying the harmful bacteria is known as sterilization.

By boiling:

Water boiled for 10-15minitues all the harmful bacteria are killed and the water becomes safe for use.

By ozonation

O

3

→O

2

+[O]

Ozone is a powerful disinfectant and is readily absorbed by water,

By using UV radiation

Using for sterlisizing water in swimming pool.

Cl

2

+H

2

O→HCl+HOCl

Cl

2

+NH

3

→ClNH

2

+HCl

ClNH

2

+H

2

O→HOCl+NH

3

CaOCl

2

+H

2

O→Ca(OH)

2

+Cl

2

Cl

2

+H

2

O→HCl+HOCl

HOCl+ Bacteria→ bacterias are killed

Break point chlorination:

Water contains following impurities:

1.bacterias

2.organic impurities

3.redusing substances(Fe 2+ ,H

2

S etc)

4.Free ammonia

Boiler feed water:

The water feed into the boiler fo the production of steam is called boiler feed water

Boiler troubles: 1.scale&sludge formation

2. priming&foaming

3. caustic embrittlement

4. boiler corrosion

Sludge: if the ppt is loose and slimy it is called sludge .sludge are formed by substances like MgCl

2

,MgSO

4

, Cacl

2

Scale: if the precipitates forms hard adherent coating on the inner walls of the boiler like Mg(OH)

2,

CaSO

4

S.NO sludge scale

1

2 sludge is a loose ,slimy and non adherent precipitate.

The main sludge forming substance are

MgCO3,CaCl2 etc. scale is a hard, adherent coating.

The main scale forming substances areca(HCO3)2,Mg(OH)2

3 Disadvantages:sludge are poor conductors of heat.excess of sludge formation decreases the efficiency of boiler.

Disadvantages: scales act as a thermal insulators.it decreases the efficiency of the boiler.

4 sludge formation can be prevented by using softened water.

Sludge can also be removed by using blow down operation. scale formation can be prevented by dissolving using acids like

HCl,H2SO4 scale formation can also be removed by external,internal treatment.

Priming&foaming:

Priming is the process of production of wet steam .priming is caused by

1.High steam velocity

2.Very poor boiler design.

Foaming (the formation of stable bubbles above the surface of water is called foaming.

Foaming is caused by presence of oil.& grease. Presence of finely divided particle.

Caustic embrittlement:

It means intercrystaline cracking .boiler water containsNa

2 co

3

Na

2

CO

3

+H

2

O→2NaOH+CO

2

Fe+2NaOH→Na

2

FeO

2

+H

2

↑

Boiler corrosion:

Corrosion in boilers is due to the presence of →→

1. Dissolved O

2

2. Dissolved CO

2

3. Dissolved salts

4. Fe+6H

2

O+3O

2

→4Fe(OH)

3

2Na

2

SO

3

+O

2

→2Na

2

SO

4

N

2

H

4

+O

2

→N

2

+2H

2

O

Mechanical de-aeration method:

The high temperature &low pressure produced inside the tower dissolved oxygen content of the water.

CO

2

+H

2

O→H

2

CO

3

2NH

4

OH+CO

2

→ (NH

4

)

2

CO

3

+H

2

O

MgCl

2

+2H

2

O→ Mg(OH)

2

+2HCl

Fe+2HCl→ FeCl

2

+H

2

↑

Softening(or)conditioning method:

The process of removing hardness producing salts from water is known as softening(or)conditioning of water.

This method can be done in 2 methods

1.External conditioning

2.Internal conditioning

External conditioning:

Ion exchange (or) demineralization process.

Cation exchanger:

Resins contains acidic functional groups (COOH,SO

3

H) cation exchange resin is presented as RH

2 ex: 1.sulphonated coals.

2.Sulphonated polystyrene RSO

3

H

Anion exchanger:

Resin contain basic functional groups (NH

2

,OH)Anion exchange resin is representated as R(OH)

2

RH

2

+CaCl

2

→RCa+2HCl

RH

2

+MgSO

4

→Rmg+H

2

SO

4

RH+NaCl→RNa+HCl

Regeneration:

RCa+2HCl→RH

2

+CaCL

2

RNa+HCl→ RH+NaCl

R’Cl

2

+2NaOH→R’(OH)

2

+2NaCl

Carbonate conditioning: scale formation can be avoided by adding

Na

2

CO

3

to the boiler water.

CaSO

4

+Na

2

CO

3

→CaCO

3

+Na

2

SO

4

Phosphate conditioning: scale formation can be avoided by adding sodium phosphate.

3CaSO

4

+2Na

3

PO

4

→Ca

3

(PO

4

)

2

Trisodiumphospate Na

3

PO

4

(Weakly alkaline) used for too acidic water.

Disodium hydrogen phosphate-Na

2

HPO

4

(weakly alkaline) used for alka weakly acidic water.

Sodium dihydrogen phosphate-NaH

2

PO

4

(acidic) used for alkaline water.

Calgon conditioning:

Calgon is sodium hexa meta phosphateNa

2

[Na

4

(PO

3

)

6

]

2Caso

4

+Na

2

[Na

4

(po

3

)

6

+→Na

2

[Ca

2

(PO

3

)

6

]+2Na

2

SO

4

The complex Na

2

[Na

4

(po

3

)

6

] is soluble in water and there is no problem of sludge disposal. So calgon conditioning is better than phosphate conditioning.

Zeolite process:

Hard water contains Ca

2

+&Mg

2

+ ions this ions form hard soap (in soluble)with soap which does not produce lather with soap soln.

Hard water is softened by passing it through a column packed with sodium cation exchange resin (called sodium zeolite )

Na

2

Ze+Ca 2+ →CaZe + 2Na+

Synthetic zeolite is represented by Na

2

Ze. The sodium ions which are loosely held in Na

2

Ze are replaced by Ca

2+ and Mg

2+ ions present in the water.

Process:

Sodium ions with Ca

2+ and Mg

2+ ions present in the water to form Ca and Mg ions present in the water.

Ca(HCO

3

)+Na

2

Ze→ CaZe+2NaHCO

3

Mg (HCO

3

)+Na

2

Ze→ MgZe+2NaHCO

3

CaSO

4

+ Na

2

Ze→ CaZe+Na

2

SO

4

Mg SO

4

+ Na

2

Ze→ Mg Ze+Na

2

SO

4

CaCl

2

+Na

2

Ze→ CaZe+2NaCl

Mg Cl

2

+Na

2

Ze→ Mg Ze+2NaCl

Regeneration:

CaZe+2Na

+

Cl

-

→Na

2

Ze+CaCi

2

Desalination of brackish water:

The process of removing common salt from the water is known as desalination.

1.Fresh water -<1000ppm of dissolved solids

2.Brackish water-contains >1000ppm but <35000ppm of dissolved solids .

3.sea water –contains>35000ppm of dissolved solids.

Reverse osmosis(RO)

Two solutions of different concentrations are separated by a semi permeable membrane.

Flows from a region of lower concentration to higher concentration.

This process is called osmosis.

Solvent flows from higher concentration to lower concentration.this is called reverse osmosis.

Advantages:

1. The life of the membrane is high,and it can be replaced with in few minutes.

2. It removes ionic as well as non –ionic, colloidal impurities

3. Due to low capital cost, simplicity.