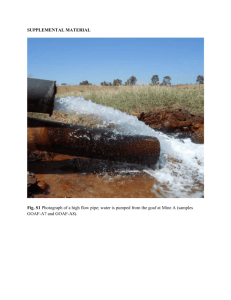

Mine Health and Safety Act

advertisement

Mine Disasters and Lessons ©Mar. 21, 2006 Dr. B. C. Paul Easy to Forget How Common it Used to be for Mines to Blow Up 140 120 100 80 2000s 1990s 1980s 1970s 1960s 1950s 1940s 1930s 1920s 1910s 1900s 1890s 1880s 1870s 1860s 1850s 1840s 1830s 4000 3500 3000 2500 2000 1500 1000 500 0 Decade 60 40 20 0 # of Explosions and Fires # Killed Frequency of Mine Explosions and Fires # Killed # Mines Recent Disasters (since 1969) #1 #2 #3 #4 #5 #6 #6 #7 #8 #9 #9 #9 #10 #10 #11 #11 #11 #12 #12 #12 #12 #12 2/26/1972 12/30/1970 12/19/1984 3/9+11/1976 4/15/1981 9/23/2001 12/8/1981 1/2/2006 9/13/1989 8/6 + 8/16 2007 7/22/1972 3/1/1977 12/7/1992 12/7/1981 6/21/1983 1/20/1982 7/23/1966 2/6/1986 12/16/1972 4/4/1978 11/7/1980 May-06 Buffalo Mining Co. Finley Coal No. 15 & 16 Emory Mining Co. Wilberg Mine Scotia Mid-Continent Resources Dutch Creek #1 Jim Walter Resources, Inc. #5 Grundy Mining #21 Sago Mine Pyro Mining Co. No. 9 Slope Wm. Station Genwal Mine Worst Since 1969 Saunders, WV Hyden, KY Orangeville, UT Whitesburg, Ky Redstone, CO Brookwood, AL Whitewell, Tn WV Sullivan, KY Utah Blacksville #1 Porter Tunnel Southmountain Coal Mine #3 Adkins Coal Mine #11 Clinchfield Coal McClure #1 #1 Siltex Mine Loveridge No. 22 Itmann No. 3 Moss No. 3 Farrel 17 Darby Blacksville, WV Tower City, PA Norton, VA Kite, KY McClure, VA Caynor, Ky Mt. Hope, WV Fairview, WV Itmann, WV Duty, VA Uneed WV Kentucky 125 Coal 38 Coal 27 Coal 26 Coal 15 Coal 13 Coal 13 Coal 12 Coal 10 Coal 9 Coal 9 Coal 9 Coal 8 Coal 8 Coal 7 Coal 7 Coal 7 Coal 5 Coal 5 Coal 5 Coal 5 Coal 5 Coal Dam failure Explosion Fire Explosion Explosion Explosion Explosion Explosion Explosion Chain Pillar Collapse Explosion Inundation Explosion Explosion Explosion Explosion Explosion Collapsed coal pile caused suffocation Explosion Inundation Explosion Explosion Buffalo Creek • Not really a mining accident per say • Rains weakened and overtopped a tailings pond dam • The dam collapsed sending water down narrow canyons – In WV people live mostly in the river bottoms – Canyon structure acted as a shot gun barrel wiping out towns and the people in them. Findley Disaster of 1970 #2 • Dec 30 1970 Explosion killed 38 – 1969 law was new and being transitioned in. – Mine had a proven history of allowing coal dust to accumulate, doing poor rock dusting, and blasting anyway they felt like. – They loaded up over 100 holes into the roof – loaded with cartridge explosives that were not permissible – stemmed the holes with curtain scraps (unconfined shot) and fired them all at once (instead of 20 at a time) – Shot stirred up and ignited dust sending a powerful coal dust explosion through the mine • 31 killed instantly rest within a short time from CO #3 Wilberg Disaster of 1984 • Dec 19, 1984 a defective compressor that had its safeties bypassed caught fire. – Two miners working on the beltline discovered the fire and attempted to extinguish it unsuccessfully – Fire spread to the belt line and the fire suppressant foam nozzle and extinguishing system failed to go off properly – Miners evacuated and spread the alarm. Meanwhile Back at the Longwall • Longwall was about to complete a worlds production record – Several company officials were on hand. – Warning was phoned to the section of an out of control belt fire • People apparently ignored the warning and did not attempt to put on their filter self rescuers (a filter self rescuer is carried on miners belt and catalyzes conversion of CO to CO2) Back on the Belt Line • Fire spread out of control burning through the stoppings into the escapeway – The mine had been allowed to operate with a fall in the returns so it could not be used as an alternate escape. • Toxic atmosphere now flooded down the airsupply into the longwall area. At the Longwall • Miners became confused as smoke and toxic gasses flooded in – 13 of 27 people on section scrambled for self rescuers • Rest were cut down by CO before they could figure out what to do (remember fire or explosion often brings black out conditions with toxic air and moves in as a wave) – Weakness of Filter Self Rescuer is it provides no self contained atmosphere. • SCSRs are like bulky back packs since 1980 had to be stored near section The Survivors Try To Escape • 3 of the Survivors tried to exit using their filter self rescuers but were cut down before they could get to SCSRs – May have waited to late to put them on or breathed around FSR • Mouth piece becomes hot enough in CO to blister your mouth – but if you twinge or open your mouth your dead • 4 more were confused and walked past the SCSRs – As they advanced toward the fire area the oxygen was depleted by the fire and they suffocated. 6 Survivors Get to the SCSRs • 4 of the men tried to change from FSR to SCSRs but they didn’t get them on before they tried to breath – the CO cut them down • 1 changed to an SCSR and tried to escape but ran out of air or mistakenly inhaled – SCSR’s have a reputation for being very hard to breath through – especially under exertion or stress. • One grabbed three rescuers and changing them as he went – He cleared the fire and got to safety (well sort of) • He took his SCSR off when he was sure it was safe – it wasn’t • 27 people died – the entire longwall section and visitors including first women killed in a coal mine disaster. Wilberg Summary • Wilberg is most serious mine disaster of recent time stemming from – Pure Stupidity – Intentional violation of the regulations – Poor training in the handling of rescuers • Criticism of MSHA for issuing a variance allowing mine to operate with secondary escapeway through the returns blocked. – Only one person made it far enough for blockage to have been an issue and he got through Scotia #4 – 26 killed • SE mains had poor ventilation. Methane feeders developed. Mine did not send Fire Boss into the entries to inspect before the shift, but did send and electric loco in that had been modified so that wiring exposed an ignition source – MESA believed the loco that reached the area as it exploded set off the blast – Mine prefers the story that a rock outburst dropped rock and created a spark as the train went by • The blast on March 9, 1976 killed 9 people. Six more fled back into a mined panel and tried to barricade. The barricade leaked and the miners died • Rescuers got all the bodies out in 18 hours Recovery of the Scotia Mine • MESA inspectors began working down SE entries to restore ventilation and investigate • They had a major roof fall, sent in a tracked bolter to work on things and clean them up – Didn’t check for methane build up – When they powered on the section and the bolter the mine blew up again – Mar. 11, 1976 – Killed 11 more people – Mine was sealed for a year because of more explosion fears. Highlighted Lessons • Rescuers go into an un-stabilized environment and are at risk from 2ndary explosions • Mine explosions damage ventilation networks • Miners trying to set up quick barricades often have problems with barricades leaking CO • People who don’t check their mine atmospheres can get blown up – even when their badge says MSHA Dutch Creek #1, April 15, 1981 #5 • 15 Dead • This was a deep mine at 2700 ft using longwall – The mine was prone to rock bursts and release of accompanying methane pockets – Defense against explosions • Methane detectors de-energized circuits quickly • Enclosed “intrinsically safe” permitted circuits • Rock dusting and dust clean-up to prevent explosions from propagating • Self rescuers for miners to protect themselves from carbon monoxide. The Event • B shift started at 3:00 PM – Mine blew up between 3:55 and 4:10 (hysteria prevents knowing exactly) – Personnel who could left the mine, and calls went out to management, MSHA, and rescue teams • Rescue efforts commenced to account for 19 missing people at 5:17 – Took just a little over an hour to get response going – First trip got 4 people out by 6:39 Blast Damage – A Frequent Problem • Teams generally work in pairs alternating advance into the mine (still done today) – Teams found stoppings blown out and had to repair roof and ventilation structure to advance – Need to establish fresh air as they advance • If you don’t do this you run the risk of blowing the mine again with your rescue teams inside. – By time they reached the intake to the 102 section (a continuous miner advance section) they were looking at a smashed up power station • Fairly sure by 10:30 that chances of finding remaining 15 alive were slim. (a 15 psi over-pressure will smash a human body) – As the teams advanced into the section they started pulling out bodies What Went Wrong • Mother nature had another rock-burst that spread broken coal all over and released a cloud of methane – Most of the equipment worked and miners and face shut down – Except the lights on miner • Lights were an after market rig up • It had been done in 1978 and never hooked up to the safety system (which was why it didn’t go off) • On April 6, 1980 a second jury rig put the switch in a box that didn’t seal tight. Saga of a Disaster • One of the continuous miner operators went and turned the non-cooperative circuit off – The breaker arced and the box was not sealed properly – The spark ignited the methane pocket – The rock burst had put fine coals dust all over the face • The methane explosion picket up the coal dust and initiated a full fledged blast wave. People Die • Six miners were right on the face – Three of the six were killed instantly from blast concussion – Another was severely injured but died a short time later from CO poisoning – Two escaped the blast but did not get their rescuers on before the CO got them • Two miners were bringing a shuttle car away from the face – The strengthening blast wave picked up coal dust from the shuttle car and clobbered the two miners dead from the concusion • Seven out-by support people and operators escaped the concussion but died of CO poisoning. Causes • Natural mine dangers – rock bursts • Jury-Rigged circuits – Probably a lot of small fires associated with half cocked jury-rig wire ups – Jury rigged circuits don’t perform to spec when the chips are down – Had circuit been right the rock burst would have shut the mine face down until the methane cleared – Jury rigged circuits don’t kill people by the grace of God • If his grace is not on the job-site then somebody is going to get dead. Causes Cont. • Coal Dust – Coal dust adds to blast power but cannot ignite itself – A methane ignition will set it off and give it the power of a high explosive – Reason keeping coal dust clean and faces dusted is sooo important. – In this case the rock burst put down the coal dust blanket or there was some on top of the shuttle car or feeder. • Avoiding this dust by clean-up would have been hard Lack of Fast Worker Response • Only 5 of the 15 people were killed by the blast even though they were in the middle of it. – One more was injured badly and could not have been expected to get on a self rescuer – Two more on the face didn’t have much time – About 7 people would have had a little more time after the swoosh of the blast wave • Ability to get a rescuer on fast might have made a big difference Grundy #21 Tied for th 6 Place • Whitewell Tennessee Dec. 8 1981 – Grundy was a room a pillar mine. • Methane ignition blast occurring at 12:00 noon • Illustrates the issue of old mine workings – Abandon workings cave and gob / can get methane build ups – One approach is to run-ventilation around edge of the Gob to draw out and dilute methane. • Alternative is to seal the area off all together to keep out oxygen. – Grudy used perimeter ventilation around the GOB The Grundy Event • Ventilation around GOB was not keeping methane down in a GOB and it was leaking into the Section #3 face area – At 7:00 AM Section 3 had 5% methane in the GOB and coming out – Determined to try to drill holes ahead to flush out the methane build up using ventilation air Working with Geniuses • Had a crew of 13 people on a mining face trying to drill through to bleed away dangerous and explosive methane concentrations – Ventilation regs specify that can’t have but the last few cross cuts open for fear of short circuiting ventilation air needed to keep methane down. • Lack of open cross cuts increases shuttle change out time and reduces face productivity • They had left extra cross cuts open and were shorting fresh air away from the face where methane was building up – Bozo Breath is up on the face fighting methane build up and pulls out a cigarette and lights it up. • CAPITAL LETTERS ON GIVE ME A LIGHT! – He blew the whole crew up What Went Wrong • Mine had been short cutting on ventilation to the face area – leaving opportunities for methane build up • Mine had been sloppy in maintenance of perimeter ventilation around GOB area • Poor ventilation practices allowed methane build-up • Mine was lax in smoking enforcement – Had not had an inspection for two months even though mine policy called for weekly – Smoking was widespread and smoking materials were scattered all over the mine • Someone knew or should have known smoking policies and safety was being neglected. The Crown Jewel • How could someone be so stupid that they are on a face fighting methane – measuring explosive concentrations coming out of a GOB and then light up a cigarette with 12 of his buddies standing there? What Did Not Go Wrong • Face had just been rock dusted on the previous shift and there was no coal dust explosion wave to kill anyone else Moral of this Story • If you wonder why MSHA kicks individual “butt” for smoking violations maybe carrying out 13 dead bodies will help illustrate. • #2 Illinois Worst Mine Disaster of all time was the Orient #2 blast just before Christmas in 1951 – 119 dead bodies spread out on the High School Gym floor – A Christmas thousands of widows, orphans, and close relatives will never forget – A family legacy in West Frankfort to this day – Ignited by a miner lighting up a cigarette. Cigarettes Still Kill • South Mountain Virginia Dec. 7, 1992 (10th place) – A poorly ventilated GOB began releasing very localized methane pockets – A miner with a butane lighter – lights up on a face • (unlike Grundy he wouldn’t have known that methane was a big hazard) • He blows his whole crew of 8 to heck except the belt attendant who made it out with his injuries – Rock dusting on the maintenance shift just before the production shift saved mine from a general explosion that could have killed a mine full. Jim Walter Resources #6 tie • Sept 23, 2001 (right after 9/11) – Crew of three was setting up cribs near a battery charging station to respond to bad roof – A fourth person was delivering supplies – 32 people were in the mine • The roof fell on the battery station – Smashed up one battery and released a pocket of methane – The battery arced and blew the methane at 5:20 pm • 1 miner received near fatal injuries – others were very hurt but managed to make their way out and to sound the alarm The Rescue Begins • The initial blast blew out the ventilation controls in the area reversing flows and cutting dilution of leaking methane gas • Miners de-energized the electrical system to cut spark ignition sources and then teams from other areas of the mine moved in to rescue the injured miner Who Rescues the Rescuers? • First team of 5 advanced through debries on the track haulage system and found the air flows reversed – Without any gas detection equipment they met 4 others and advanced into the damaged area • Team of 3 communicated to section foreman and went in to rescue the miner • They had remembered to turn off all the high voltage but forgot about the traffic lights on the haulage system – The methane build-up ignited at 6:20 pm this time picking up sloppy coal dust accumulations and sending a firestorm wave through several sections of the mine • 11 of the advancing rescuers were blown to bits – One was severely injured – Regular rescue teams picked him up but he died the following day A Lesson In Mine Rescue • Teams are advancing into unstable conditions – Reason need to advance ventilation with them – Charging in like a hero may not be heroic Sago Mine Jan 2 2006 (7th Place) • Setting the Stage – Mine was working a panel but roof conditions were bad – determined they would pull out of the panel • The mine pillared on retreat (the usual practice) – Some sources criticize for aggressive pillaring which made it unsafe to go in and measure but the panel was to be sealed • The panel was sealed off – supposedly tight and work went on for several months Opening the Mine • After the holidays the mine was pre-shift inspected at 5:50 am on Jan 2, 2006. – First crew of 12 miners entered shortly there after – A second man trip began around 6:00 • Shortly before 6:30 the mine exploded by 6:30 sensors were reporting CO moving through the mine – The stoppings on the recently sealed panel were blown to pieces by pressures as high as 60 psi • Pattern suggests a blast may have originated behind the seals • One man walking the entries near by was apparently killed in the blast – The first mantrip was past the explosion area probably at their working face – The second mantrip had not reached the seals and turned back – Communication to the face where the first crew had gone was cut off by blast damage to phone lines • (one news column criticized the operator for not using cell phones but you know they don’t work underground) A Fiasco Begins • Foreman on the second mantrip (his brother was trapped), the Superintendent and 3 others made a rescue attempt doing quick repairs to blown out ventilation stoppings – Advancing 9,000 feet into the mains – CO readings were high and the air shifted into the mine might set off a second explosion • They pulled back • At 7:40 the mine issued instructions to begin calling for help – At 8:04 the rescue team at another mine was called for help (you can use rescue teams up to 2 hours away) – At 8:10 calls reached MSHA but the contact people were still out of the office on vacation – At 8:30 someone at MSHA was called and official “immediate” notification was given (the explosion had occurred by 6:30) Help Arrives • MSHA arrived at 10:30 and took control of the rescue and all public relations (using two people who had never experienced a mine disaster before) • The Mine Rescue Team arrived at 10:40 – Rescue teams could not be released immediately • Drill rigs arrived and began drilling holes into the panel area where the first crew would have gone to work • By around 10:30 to 11:00 PM the rescue teams were allowed to begin advancing into the mine Bad News • Robot sent ahead of the teams to probe got a flat tire and almost tipped over about 2,500 ft in. • By 3:40 am Jan 3, 2006 the advancing rescue teams had to be pulled out – Teams advance 500 feet at a time securing fresh air behind them – they call in and the next team moves past and advances • On a good day you can get 1,000 ft/hour – Problem was they found air monitor network had been left on when the mine powered down – this meant a potentially damaged ignition source was still running – The drill was near the 280 foot depth mark and would soon penetrate the mine – if the bit sparked it could ignite an explosion • The hole was punched through – The air was 1300 ppm CO (400 maximum tolerable level) – Borehole cameras saw nothing • Mine Rescue teams could not be released again till 6:20 am Looking for Hope • In a toxic atmosphere from which no one had emerged hope was that the miners had barricaded and saved enough air to wait for rescue • Shortly before Midnight the advancing rescue teams found body of a miner killed by the blast. • Mine rescue teams communicated on an open channel and as teams neared working face the press poised for news • Around 1:00 am Jan 4 the rescue teams arrived at the face. They found a barricade built of blocks and plastic and 12 men down but wearing breathing apparatus – “We found 12” said the rescue team – “Are they alive”? Ask the coordinator – “I think so” responded an optimistic team member who had not checked any of the bodies • The press had the story before the Mine Officials and broadcast the news – ambulances raced to the site and Church Bells Rang Hopes Fall • By about 1:30 Hatfield CEO of International was told the report was wrong – Hatfield ask a State trooper to tell people celebrating at the Church that there were now conflicting reports • The communication never arrived • At 4:00 word reached the celebrating crowd that all but 1 were dead • The next day copies of last letters written by loved ones trapped underground were released to the families – Barricade had leaked CO and the air supplies the miners had were not adequate for the 41 hours it took for the rescue teams to reach them. Why Did the Mine Explode? • A Explosive Atmosphere developed behind a sealed panel as methane built up and oxygen was not yet depleted • Early reports blamed a lightning strike at the shaft (but people were near the shaft and saw no such thing) • Lighting detection network picked up two strikes above the mine – One at 6:26:36am a large 35Kamp strike occurred above the panel that appears to have exploded (22 Kamps is a normal strike) – Siesmographs picked up a small seismic event in the area of the mine at 6:26:38am (possibly the explosion) – By 6:30 the methane detection network at the mine was going off extensively How Could Lightning Blow An Underground Panel? • No conductors found to take the line underground • Electricity can produce a magnetic pulse which can travel underground • An old cable had been left running to an abandoned pump – Cable acted as an antenna – The magnetic pulse generated the electricity that arced from the pump The Anti-Thesis of Jim Walters • An issue constantly present in disasters – Not killing the rescuers – Previous disasters had killed rescue crews but Jim Walters was recent. • Rescue Crews get suckered at Sago – Most mine explosions occur on the face or around active equipment areas • A few old ones around ventilated gobs and left open old workings but Sago was sealed – Severity of the damage was apparent long from the face • It could only get worse going to the face • There could be no survivors • Went in cautiously to avoid getting people killed – played with their little robot toy But it Wasn’t True • Damage was bad where the seal blew • The face was undamaged and people were trapped from exiting • Rescue crews played it safe (and played in general) – People died of monoxide as their rescuers on the face ran out of air – Poor communications and some lack of grace by rescuers made things look even worse Sending People Reeling – Alma Mine • Alma Mine #1, January 19, 2006 – 5:01 mine belt inspector finds haze and alignment problems on a belt – he tries to correct it – When he can’t he shuts down the belt and calls for equipment to align • He notices smoke forming and calls in a report and help is dispatched. – 5:14 beltway CO alarms go off – office determines not to take action because they have people on the scene already Fire Fighting – Polish Style • Help arrives and they discharge fire extinguishers at the fire (which is now catching the rib) – fire bounces back • They go hook up the fire hose – No one paid attention to coupling compatibility – Someone had shut off the water • They went searching for more extinguishers and to find out where the water was shut off • They found the water shut-off and got water to the area but the fire was now out of control – Reported immediately to the surface where an evacuation order was issued (28 minutes after the first alarms) Evacuation • Trouble getting section 2 crew alerted but the foreman got them together and laid out the plan – They would go out the primary escapeway and if that failed they would cross over into the beltway (2ndary escape) • He picked an area with a lot of cribs that would be easy to find under adverse conditions – Door was new, not marked, many were not familiar with it You Can’t See in a Fire • Mantrip went to where smoke was so dense they could not see – Stoppings to isolate the belt from the intakes had been removed and smoke from the fire got into the intakes • Inspectors had no equipment to check air flow directions and had not found the problem • Miners got off and began putting on SCSRs – They said they put them on right away but cases indicate many went quite away before trying to put them on. CO and Orientation • Even lower CO concentrations can impair judgment before killing you – Miners were trying to put on equipment kneeling toward the floor with about 1 foot of visibility – They dropped goggles and could not find them, had trouble activating rescuers – They could not see each other to keep track and people were dropping down to put on SCSRs at random • They went through the door to mostly clear 2ndary Escapeway and found 2 missing – 3 went back to call and look in the smoke but found nothing – They determined to get the rest out – (2 missing men were later found dead) Some Observations • Catching dangerous situations before hand is important – If inspectors had been equipped to check ventilation air they would have found open stoppings that allowed smoke into the primary escapeway – Coal dust accumulations on belt line and not staying on top of belt maintenance contributed • (although belt inspector did do some shoveling) • Irregularities become MSHA vengeance points if something goes wrong – Mine was clobbered for 28 minute evacuation delay even though they had a crew on scene at the fire and were in active communications – Mine was clobbered over the escapeway door • Foreman planned and clearly explained the evacuation • He picked a coordinated point with maximum chance of finding the door to switch to the 2ndary if needed even before knowing escapeway was in trouble • The door was not marked (never mind that miners could not find their goggles on the floor in front of them) – MSHA blamed heavily • 1.5 million dollars in fines, including reckless disregard charges More Observations • Little day to day Polish things set up a killer scenario • Putting on a rescuer in smoke is very different than a class room – People are slow to put on rescuers (remember a little monoxide will blow the edge off your judgment) – Staying together is important (should miners tether-up to each other?) 2006 Triple Play – Darby – May 20, 2006 1:00 AM – The production shifts were out And the maintenance shift was going into Full swing (6 people were in the mine) The Fatal Mistake – two of the workers Went to fix the A left seals Metal roof straps were left going through The seals preventing flexible wood seal at The top. Crew went to cut the straps Cutting is done with torches but one must Check the methane readings around the Area before lighting up Crew did not sample methane (relied on The pre-shift) and had no way to know what Was behind the seals Blow Up • The two started cutting by the seal with an explosive mixture behind – It ignited • Production crew was no sooner out of the mine than a swoosh of air followed by a burnt coal smell came out – MSHA was called by 1:05 (5 minutes) – Mine pieced together a jury rigged team to go in with some trained rescuers Action Underground • The explosion blew out the seals – Force of the explosion killed two workers – One body was found 240 ft away, the other 340 ft away. This is their personnel Carrier wrapped around Conveyor belt structure 4 Miners Felt the Blast and Determined to evacuate • They hopped on a personnel carrier and headed out • Traveled only a short distance and encountered thick vision obscuring smoke – They put their SCSRs and drove on. You Can’t See After A Blast After just 300 ft the carrier Ran aground on a blown Out overcast (it was 3800 feet to the Surface) They got out and tried to Walk on through the Darkness They made it to a power Center and pulled out Their mouth pieces to talk One thought he found a Power cable to follow – the Others went back – all Became disoriented The Fate of the Miners • Two apparently took out their mouth pieces and collapsed (they were found dead) • Another found dead also • One who followed the cable to the surface passed out – but revived and tried to crawl to the surface – The jury rig rescue party got to him in time • Miners had not kept breathing through their SCSRs – – – – Hard to breath and exerting Pulled out to talk Did not stay together A little monoxide will fog your mind and judgment before killing you (that’s all it takes to finish you) Genwal, Aug 6, 16, 2007 Chain pillar failure closed all 4 entries for 2,000 feet and likely Buried 6 miners on a working section A Killer Rescue Aug. 16, 2007 3 more die trying to mine through the collapse to rescue The miners What Went Wrong • Official accident report is not out so things are speculative • Genwal was trying to mine up through reserves between pillared panels – It is likely the mine plan considered average overburden and not variations in overburden thickness – It was a chain pillar collapse (only one in U.S. coal) • MSHA is in a bad spot with vengeance investigation – Mine plans were prepared by hired consultants and were approved by MSHA – Mine was following the plan – Trying nit pick violations won’t help much – this was very fast and the killer problem was a flawed plan – How do you blame someone else when you signed off on the plan and were in charge of the rescue that killed 3 more people? Scrambling for Lessons • How careful should you be on rescues? – Jim Walters – the fatalities were mostly rescuers – Genwal – 3 of the 9 fatalities were rescuers – Sago – the people died because the teams did not realize the blast was not from the face. Believing no one could have survived they doddled and 11 people died – Darby – a rescue team without back-up and including non-rescue personnel pulled the only survivor out because they did not doddle