CHEMICAL REMEDIATION OF ACID MINE DRAINAGE IN MUI

CHEMICAL REMEDIATION OF ACID MINE DRAINAGE IN MUI BASIN

COAL MINE

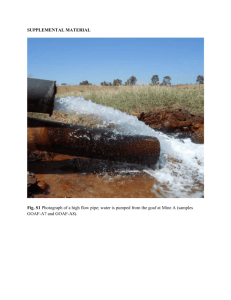

Coal mining in the Mui Basin is soon to get started. Environmental Impact

Assessment has been done and relevant pollution control measures have been put in place. Conversely, issues regarding to risks that the mine poses via Aid Mine

Drainage (AMD) top the list of environmental concerns in the area. The process of

AMD starts deep underground or with the spoils with the oxidation of the mineral pyrite (fool’s gold). This leads to the oxidation of the pyrite in two stages, the first one producing sulphuric acid and ferrous sulphate and the second stage orange-red ferric hydroxides and even more sulphuric acid. Pyrite is associated with coal and is the main host of sulphuric acid in coal. During normal weathering, acid is produced at a slow rate. This rate is slow such that natural neutralization can readily remove the acidity.

Studies showed that various physio-chemical properties of water are altered as a result of pollution. Water samples tests reveal that the levels of sulphates and Total

Dissolved Solids hit a peak high whenever drainage from the mine areas is increased during rainy times. Acidity of mine waters by dissolution of oxidized pyritic materials associated with coal and associated with strata during mining operations.

Six chemicals for AMD treatment are discussed. They are limestone, hydrated lime, pebble quicklime, soda ash, caustic soda and ammonia. Technical and financial factors influence the choice of the chemicals that will be applied. The technical factors are acidity levels, flow, the rate of chemical treatment, types and concentration of metals in the water and the desired final water quality.