Transition-Metal-Catalyzed Cross-Coupling

advertisement

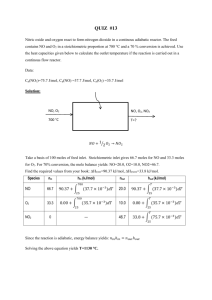

Transition-Metal-Catalyzed Decarboxylative Coupling November 13, 2007 Dino Alberico Decarboxylative Coupling Decarboxylative Biaryl Coupling O OH X R' transition-metal catalyst + R R' R X = I, Br Decarboxylative Heck-Type Coupling R' O OH R R' + transition-metal catalyst R Biaryl Compounds Natural Products OH OMe HO MeO N O NHAc MeO HO OMe CO2Me Me N H NH HO HO allocolchicine cavicularin O OH Me korupensamine A rhazinilam Agrochemicals Pharmaceuticals O N CO2H OH HO2C Cl OH N N CO2H F N N NH HN O O N N N NH Diovan (Valsartan, Novartis) Micardis (Telmisartan, Boehringer) Cl Lipitor (Atorvastatin, Pfizer) PAH Liquid Crystals N Boscalid (BASF) Ligands C7H15 C8H17O CN NCB 807 (Merck) OH OH N Me2N PPh2 PCy2 Biaryl Formation Using Transition Metals X R + transition metal Y R' R Transition Metal (either stoichiometric or catalytic): Cu, Ni, Pd, Pt, Ru, Rh, Ir X, Y: I, Br, Cl, OTf, ONs, B, Sn, Si, Zn, Mg, H Hassan, J.; Sévignon, M.; Gozzi, C.; Schulz, E.; Lemaire, M. Chem. Rev. 2002, 102, 1359. R' Ullmann Coupling X + Cu (stoichiometric or excess) X R R R R Ullmann, F.; Bielecki, J. Chem. Ber. 1901, 34, 2174. Example: MeO MeO Cu-bronze, 200 oC MOMO CONHiPr MeO MOMO PrHNOC CONHPr OMOM I NMe2 O O O O OMe 66% OMe Taspine Kelly, T. R.; Xie, R. L. J. Org. Chem. 1998, 63, 8045. Drawbacks: - stoichiometric amount of copper - high reaction temperatures - limited to symmetrical biaryls - unsymmetrical biaryl can be formed by using aryl halides of different reactivity but require a large excess of the activated aryl halide Transition-Metal-Catalyzed Cross-Coupling Y + transition metal catalyst X R organometallic Y: B, Sn, Si, Zn, Mg R' R R' aryl halide X: I, Br, Cl, OTf Suzuki Coupling OBn O B O BocN O PdCl2(dppf)2, CH2Cl2, K2CO3, DME, 80 oC, 2h BocN O O + O NHCbz I CO2Me N H 75% BnO N H NHCbz CO2Me Lin, S.; Danishefsky, S. J. Org. Lett. 2000, 2, 2575. Stille Coupling N SnBu3 + Pd(PPh3)4, toluene, 110 oC Br N N N 72% N N Sauer, J.; Heldmann, D. K.; Pabst, R. Eur. J. Org. Chem. 1999, 1, 313. Transition-Metal-Catalyzed Cross-Coupling Hiyama Coupling O Me Si(Me)2F2 + TfO Pd(PPh3)4, n-Bu4NF, THF, 50 oC, 5 h O Me H H 92% Hatanaka, Y.; Hiyama, T. Synlett 1991, 845. Negishi Coupling MeO Me S ZnCl + Br MeO PdCl2(dppf), THF, rt, 1.5 h N 97% MeO Me S N MeO Bumagin, N. A.; Sokolova, A. F.; Beletskaya, I. P. Russ. Chem. Bull. 1993, 42, 1926. Kumada Coupling Pd(PPh3)4, THF, rt, 2 h S MgBr + I CN CN 73% S Amatore, C.; Jutand, A.; Negri, S.; Fauvarque, J.-F. J. Organomet. Chem. 1990, 390, 389. Direct Arylation Cross-Coupling Y + transition metal catalyst X R R' organometallic Y: B, Sn, Si, Zn, Mg R R' R R' aryl halide X: I, Br, Cl, OTf Direct Arylation H R + transition metal catalyst X R' X: I, Br, Cl, OTf B, Sn, Si, Mg, Zn Challenge: - how to arylate a typically unreactive aryl C-H bond - how to selectively arylate an aryl C-H bond 1. Alberico, D.; Scott, M. E.; Lautens, M. Chem. Rev. 2007, 107, 174. (Shameless Promotion) 2. Seregin, I. V.; Gevorgyan, V. Chem. Soc. Rev. 2007, 36, 1173. Direct Arylation Intramolecular Direct Arylation X R2 transition metal catalyst Y R1 Y R1 H R2 Examples: Me o-Tol o-Tol O P O Pd Pd O P O Oi-Pr o-Tol Me o-Tol O O Br Me (10 mol%) NaOAc, DMA, 140 °C 5' N OH OMe Oi-Pr O O HO Me 74% N Bn Me NH Bn OH Me Oi-Pr Me Oi-Pr Me P korupensamine A Bringmann, G.; Ochse, M.; Götz, R. J. Org. Chem. 2000, 65, 2069. NO2 O2N Cl O O O O Pd catalyst Cl NO2 Julie Côté, Shawn K. Collins O2N Direct Arylation Intermolecular Direct Arylation – Using a Directing Group DG DG H transition metal catalyst X + R Directin Group (DG): OR OH O H N NHR OH R' R R' O O R H NHR O O NR RN N N N N N Examples: O Br N [RuCl2(6-C6H6)]2, (2.5 mol%), PPh3, K2CO3, NMP, 120 °C Ph O N + 100% Ph (2.5 equiv) Oi, S.; Aizawa, E.; Ogino, Y.; Inoue, Y. J. Org. Chem. 2005, 70, 3113. N+ N- + Pd(OAc)2, P(tBu)3, K2CO3, M.S., toluene, 125 °C N+ N- Br O Alexandre Larivée, James Mousseau, André Charette 80% O Direct Arylation Intermolecular Direct Arylation – Electronic Bias of Heterocycles transition metal catalyst X + Y Y N N R N N R N O S N R N O N N R N N N R O O N S N N N N N N N N N N O N R N Examples: Pd(OAc)2 (5 mol%), PPh3, Cs2CO3, DMF, 140 °C N I + N N N 83% Pivsa-Art, S.; Satoh, T.; Kawamura, Y.; Miura, M.; Nomura, M. Bull. Chem. Soc. Jpn. 1998, 71, 467. + Pd(PPh3)4 (5 mol%), KOAc, DMA, 150 °C S Br NO2 66% S NO2 Ohta, A.; Akita, Y.; Ohkuwa, T.; Chiba, M.; Fukunaga, R.; Miyafuji, A.; Nakata, T.; Tani, N.; Aoyagi, Y. Heterocycles, 1990, 31, 1951. N N R Cross-Coupling of Aromatic C-H Substrates H + transition metal catalyst H R H N CO2Me CO2Me 10 mol% NH CuI (10 mol%), O2, Cl(CH2)2Cl, 40 °C R' R R' MeO OH OH + N Ac Pd(TFA)2 (10 mol%), Cu(OAc)2 (3 equiv), CsOPiv (40 mol%), MeO pivalic acid, MW, 140 °C N Ac OH 85% 84% CO2Me (30 equiv) Li, X.; Hewgley, B.; Mulrooney, C.A.; Yang, J.; Kozlowski, M.C. J. Org. Chem. 2003, 68, 5500. O + Pd(OAc)2 (10 mol%), H4PMo11VO40 (10 mol%), AcOH/benzene (3:2), O2 (3 atm), 120 °C 98% Stuart, D. S.; Fagnou, K. Science 2007, 316, 1172. Stuart, D. S.; Villemure, E.; Fagnou, K. J. Am. Chem. Soc. 2007, 129, 12072. N + Pd(OAc)2 (10 mol%), benzoquinone (0.5 equiv), Ag2CO3 ( 2equiv), DMSO (4 equiv), 130 °C, 12 h N O excess Dwight, T. A.; Rue, N. R.; Charyk, D.; Josselyn, R.; DeBoef, B. Org. Lett. 2007, 9, 3137. 89% (100 equiv) Hull, K. L.; Sanford, M. S. J. Am. Chem. Soc. 2007, 129, 11904. Limitations to Aforementioned Transition-Metal Catalyzed Methods protections, lithiations, Y R + R halogenations, metallations, etc. transition metal catalyst X + organometallic Y: B, Sn, Si, Zn, Mg organometallic by-product aryl halide X: I, Br, Cl, OTf -preparation of organometallic partner can require several synthetic steps - more solvents, more purifications, more time, higher costs, more harmful to the enviroment - a stoichiometric amount of undesired, and sometimes toxic, organometallic by-product is produced H + transition metal catalyst X R R R' R' X: I, Br, Cl, OTf - challenging to control regioselectivity - for intermolecular direct arylation reactions of arenes, a directing group is needed; which may take several steps to introduce and then remove if not desired in the final product H R R' R R' + transition metal catalyst H R' R - challenging to control regioselectivity - large excess of one arene is needed - an excess of oxidant is needed (sometimes an organometallic reagent is used) R' Aryl-Aryl Bond Formation via Decarboxylative Coupling CO2H + transition metal catalyst X R R' + CO2 R R' X: I, Br, Cl, OTf Advantages (for best case scenario): - aryl carboxylic acids are ubiquitous in nature - many are commercially available and inexpensive - easier to control regioselectivity - no extra steps are needed to introduce the acid moiety - fewer purifications - use of less solvent - less time - less energy wasted www.carbonfootprint.com - lower costs - more environmentally friendly - more environmentally friendly CO2 by-product (compared to toxic organometallic reagents) Baudoin, O. Angew. Chem. Int. Ed. 2007, 46, 1373. Disadvantages: CO2 Sucks! Albert Arnold (Al) Gore Jr. Nobel Peace Prize 2007 Academy Award Winner 2007 It’s Done in Nature Enzymatic decarboxylation of orotidine monophosphate (OMP), followed by protonation of the carbanion O O O O HN HN N R O O O O H NH2 N R H O HN O O O N R C O NH2 O H O O Begley, T. P.; Ealick, S. E. Curr. Opin. Chem. Biol. 2004, 8, 508. O O NH2 Earlier Work – Stoichiometric Transition Metal NO2 O MeO OH + Cu2O (0.8 equiv), quinoline, 240 °C 15 min NO2 Br OMe 50% (1.2 equiv) (1 equiv) NO2 O OH (1.2 equiv) + NO2 Cu2O (0.8 equiv), quinoline, 240 °C 15 min I (1 equiv) "The yield of crystalline product was 10%, but can probably be improved to ca. 30%" Nilsson, M. Acta Chem. Scand. 1966, 20, 423. OMe OiPr Br iPrO N HO2C N Pd(OAc)2 (1 equiv), PPh3 (2 equiv), CH3CN / Et3N (3:1), 150 °C, 80 min O O MeO O O iPrO 97% iPrO MeO MeO MeO OiPr MeO OiPr Lamellarin L triisopropyl ether Peschko, C.; Winklhofer, C.; Steglich, W. Chem. Eur. J. 2000, 6, 1147. Catalytic Decarboxylative Coupling of Heteroaryl Carboxylates Br O H O OH N + Pd[P(tBu)3]2, nBu4NBr, DMF, MW, 170 °C, 8 min X O O N Me H OH O N Me Me Effect of the Additive: H Me N Br O OH + Pd[P(tBu)3]2 (5 mol%), additive (1 equiv), Cs2CO3 (1.5 equiv), Me N H Me N DMF, MW, 170 °C, 8 min (2 equiv) 1 (equiv) none nBu4NOAc nBu4NI nBu4NBr nBu4NCl nBu4NCl H2O nBu4NF 77% 64% 76% 86% 74% 88% 77% 9% 18% 8% 5% trace trace 11% Forgione, P.; Brochu, M.-C.; St-Onge, M.; Thesen, K. H.; Bailey, M. D.; Bilodeau, F. J. Am. Chem. Soc. 2006, 128, 11350. St-Onge Decarboxylative Coupling Reaction Pd[P(tBu)3]2 (5 mol%), nBu4NCl H2O (1 equiv), Cs2CO3 (1.5 equiv), Br O X Y OH + X Y DMF, MW, 170 °C, 8 min R (2 equiv) R 1 (equiv) Starting Materials: O O Me N O O S S OH OH Me O O O O OH OH N O OH N Me O S OH N O O OH Me Me OH Me Products: O Ph Me N Ph O O Ph N S Ph S Ph 53% Me 88% Me 86% 41% O OH O DMF, MW, 170 °C, 8 min Ph Me 74% Pd[P(tBu)3]2 (5 mol%), nBu4NCl H2O (1 equiv), Cs2CO3 (1.5 equiv), S O Ph N N Me Ph 23% O Ph no reaction 63% Me 86% Scope of the Aryl Bromide Me N O OH + Ar Br Pd[P(tBu)3]2 (5 mol%), nBu4NCl H2O (1 equiv), Cs2CO3 (1.5 equiv), Me N Ar DMF, MW, 170 °C, 8 min (2 equiv) Me N OMe 1 (equiv) Me N NO2 Me N S 77% 66% 78% Me Me N 85% N Proposed Mechanism O O Ar PdL2 O O Ar OH Ar side-product in some cases Ar reductive elimination R Ar Br oxidative addition reductive elimination O O O Ar OH PdL PdL R O Ar PdLAr Br O coordination to carboxylate followed by electrophilic palladation at C3 C2 OH C3 R deprotanation O O OH If R = H R PdLAr CO2 C3 to C2 migration and decarboxylation Comparison of Regioselectivity with Direct Arylation Pd[P(tBu)3]2 (5 mol%), nBu4NCl H2O (1 equiv), Cs2CO3 (1.5 equiv), DMF, MW, 170 °C, 8 min O S S OH Me Me 63% only product Br Pd[P(tBu)3]2 (5 mol%), nBu4NCl H2O (1 equiv), Cs2CO3 (1.5 equiv), DMF, MW, 170 °C, 8 min O S HO S Me 19% only product Br Pd[P(tBu)3]2 (5 mol%), nBu4NCl H2O (1 equiv), Cs2CO3 (1.5 equiv), DMF, MW, 170 °C, 8 min S Me Br + S Me Me S Me 3.3:1 39% Decarboxylative Coupling of Aromatic Carboxylates NO2 O Cl NO2 OH + Br Cl conditions These substrates were selected for optimization for two reasons: 1. Reactants, products, and by-products can be detected by GC NO2 H NO2 Cl Cl Cl O2N 2. The product is a precursor to Boscalid (BASF) Cl NH O Cl N Boscalid (BASF) Goossen, L. J.; Deng, G.; Levy, L. M. Science 2006, 13, 662. Goossen, L. J.; Rodriguez, N.; Melzer, B.; Linder, C.; Deng, G.; Levy, L. M. J. Am. Chem. Soc. 2007, 129, 4824. Optimization NO2 O NO2 OH (1.5 equiv) + Br Cl Cl conditions (1 equiv) Catalyst Catalyst Base (1.5 equiv) Pd(acac)2 (2 mol%) PPh3 (6 mol%) K2CO3 none PPh3 (6 mol%) CuCO3 Pd(acac)2 (2 mol%) PPh3 (6 mol%) CuCO3 Pd(acac)2 (2 mol%) PPh3 (6 mol%) CuCO3 Pd(acac)2 (2 mol%) PPh3 (6 mol%) CuCO3 Pd(acac)2 (2 mol%) P(iPr)Ph2 (6 mol%) CuCO3 Pd(acac)2 (2 mol%), CuI (30 mol%) bipyridine (30 mol%) K2CO3 Pd(acac)2 (2 mol%), CuI (1 mol%) 1,10-phenanthroline (3 mol%) K2CO3 Additives (1.5 equiv) Temperature ( °C) none 120 none 120 none 120 KF 120 KF / 3 A mol sieves 120 KF / 3 A mol sieves 120 3 A mol sieves 160 3 A mol sieves 160 Other Notable Reagents: Pd Source: PdCl2 Ligands: BINAP, P(Cy)3 Additives: KBr, NaF Base: Ag2CO3 Solvents: DMSO, DMPU, diglyme Solvent NMP NMP NMP NMP NMP NMP NMP NMP Yields 0 0 5% 32% 84% 98% 78% 98% Proposed Mechanism R' [Cu] CO2 L2Pd X decarboxylation oxidative addition R' X R [Cu]+ O transmetallation O Pd(0)L2 R' R anion exchange [Cu]+X- O R' L2Pd reductive elimination O R R R Scope of Aryl Halide A Pd(acac)2 (2 mol%), P(iPr)Ph2 (6 mol%), CuCO3 (1.5 equiv), KF (1.5 equiv), mol sieves, NMP, 120 °C, 24 h stoichiometric Cu NO2 O OH (1.5 equiv) + NO2 Ar Ar X (1 equiv) catalytic Cu B Pd(acac)2 (2 mol%), CuI (1 mol%), 1,10-phenanthroline (3 mol%), K2CO3 (1.5 equiv), mol sieves, NMP, 160 °C, 24 h Br R = H, Me, nPr, OMe, SMe, F, CN, C(O)Me, C(O)Ph, CHO, CO2Et, NO2, CF3 A: 67-97% B: 62-98% R Br Br Br Br Br OMe Br Cl Cl Cl CN I N N A: 94% B: 94% A: 88% B: 97% A: 93% B: 23% A: 80% B: 30% A: 13% B: 53% A: 14% B: 98% A: 0 B: 66% A: 12% B: 96% A: 84% B: 38% Scope of Aryl Carboxylate Pd(acac)2 (2 mol%), P(iPr)Ph2 (6 mol%), CuCO3 (1.5 equiv), KF (1.5 equiv), mol sieves, NMP, 120 °C, 24 h O stoichiometric Cu OH + Ar Ar X R (1.5 equiv) R (1 equiv) catalytic Cu X Pd(acac)2 (2 mol%), CuI (1 mol%), 1,10-phenanthroline (3 mol%), K2CO3 (1.5 equiv), mol sieves, NMP, 160 °C, 24 h Except for R = 2-NO2 Stoichiometric Cu Conditions: Works well for a wide range of aryl carboxylic acids. Catalytic Cu Conditions: Only works with 2-nitro substituted aryl carboxylic acid. Examining the Decarboxylation In order to design an effective catalyst for a range of carboxylic acids, they examined the relative reactivity toward decarboxylation compared to 2-nitrobenzoic acid. O OH Cu2O, (7.5 mol%), 1,10-phenanthroline (15 mol%), NMP / quinoline, 170 °C, 6 h H R NO2 R O CN H H iPrO O H F H OMe H H H NC H O2N 100% 40% 79% 70% 75% 28% 52% 23% Discrepancies: CN NO2 CO2H Aryl-Aryl Coupling - Stoichiometric Cu: excellent yield Aryl-Aryl Coupling - Catalytic Cu: excellent yield Protodecarboxylation - Catalytic Cu: excellent yield CO2H Aryl-Aryl Coupling - Stoichiometric Cu: modest yield Aryl-Aryl Coupling - Catalytic Cu: no reaction Protodecarboxylation - Catalytic Cu: modest yield Examining the Decarboxylation R O OH Cu2O, (7.5 mol%), 1,10-phenanthroline (15 mol%), NMP / quinoline, 170 °C, 6 h R H (KBr) NO2 CN H H No KBr: with 1,10-phenanthroline: 100% no 1,10-phenanthroline: 95% with 1,10-phenanthroline: 40% no 1,10-phenanthroline: 15% 15 mol% KBr with 1,10-phenanthroline: 100% no 1,10-phenanthroline: 95% with 1,10-phenanthroline: 25% no 1,10-phenanthroline: 10% 100 mol% KBr with 1,10-phenanthroline: 95% no 1,10-phenanthroline: 60% with 1,10-phenanthroline: 10% no 1,10-phenanthroline: 0 More General Catalytic Copper Conditions O OH + PdBr2 (3 mol%), CuBr (10 mol%), 1,10-phenanthroline (10 mol%), K2CO3 (1 equiv), mol sieves, NMP, 160 °C, 24 h Br R R (1 equiv) H O (1.2 equiv) O CO2H 61% F CO2H 69% CN CO2H OMe CO2H 76% SO2Me CO2H CF3 CO2H 46% NH CO2H CO2H 31% S 62% NHAc CO2H catalytic Cu: stoichiometric Cu: 34% 55% 42% 97% 0 91% 0 42% 79% CO2H MeO 0 41% CO2H CO2H Application – Synthesis of Valsartan 1. NBS 2. B(OH)2 + Cl Pd cat., K2CO3, H2O, TBAB, , 2 d H2N CO2Me 70-90% 69% NC NC O nBu HN CO2Me NC H O Br + O O B Pd cat., K2CO3 H2N CO2Me NaCNBH3 H 73% CO2H 1. nBuCOCl, Et3N 2. NaN3, nBu3SnCl 3. NaOH 60-85% O N no yield reported NC NC Buhlmayer, P.; Furet, P.; Criscione, L.; de Gasparo, M.; Whitebread, S.; Schmidlin, T.; Lattmann, R.; Wood, J. Bioorg. Med. Chem. Lett. 1994, 4, 29. N N N NH Valsartan (Diovan, Novartis) Application – Synthesis of Valsartan O nBu N CO2H R R HO2C + Br N NC NC N N NH Valsartan (Diovan, Novartis) R PdBr2 (2 mol%), CuO (15 mol%), PPh3 (20 mol%), KF (0.5 equiv), K2CO3 (1 equiv), mol sieves, quinoline, 170 °C, 24 h HO2C + Br (1 equiv) R NC NC (1.2 equiv) O O O H NC 71% OMe NC 51% Goossen, L. J.; Melzer, B. J. Org. Chem. 2007, 72, 7473. MeO NC 81% NC 80% Application – Synthesis of Valsartan 1. PdBr2, CuO, PPh3, KF, K2CO3, mol sieves, quinoline, 170 °C, 24 h 2. HCl O HO2C O + Br O HN H2N H 90% NC NC nBuCOCl, pyridine 98% O N CO2H 1. NaN3, nBu3SnCl TBAB 2. NaOH O N CO2Me 55% N N N NH Valsartan 39% yield over 4 steps CO2Me NaCNBH3 81% NC CO2Me NC Decarboxylative Coupling of Electron-Rich Aryl Carboxylates Optimization: OMe CO2H + I OMe 90% OMe (1.3 equiv) PdCl2 (30 mol%), AsPh3 (60 mol%), Ag2CO3, (3 equiv), DMSO, 150 °C, 6 h OMe OMe OMe (1 equiv) Other Reagents Examined: Catalyst Source: PdCl2(MeCN)2, Pd(O2CCF3)2, Pd(CN)2, Pd(OAc)2, Pd(dppf)2Cl2(CH2Cl2)2, Pd(PPh3)4, Pd2(dba)3, NiCl2(PPh3)2, Ni(acac)2 Ligands: BINAP, P(Cy)3, DavePhos, xanthphos Additives: LiBH4, LiCl, MgCl, CaCl2, CsCl, BiCl3, CuI Base: Li2CO3, Na2CO3, K2CO3, Cs2CO3, AgOAc, TMSOK Solvents: DMA, DMF, DMSO/DMF mixtures, sulfolane Becht, J.-M.; Catala, C.; Le Drain, C.; Wagner, A. Org. Lett. 2007, 9, 1781. Scope of Aryl Carboxylate CO2H + I OMe R R OMe OMe MeO OMe OMe OMe OiPr OMe OMe 75% 65% OMe OMe F F OMe OMe 79% 65% F OMe NO2 MeO OiPr Br NO2 OMe PdCl2 (30 mol%), AsPh3 (60 mol%), Ag2CO3, (3 equiv), DMSO, 150 °C, 6 h OMe F 63% F F 92% Cl 82% O 65% Scope of Aryl Iodide OMe PdCl2 (30 mol%), AsPh3 (60 mol%), Ag2CO3, (3 equiv), DMSO, 150 °C, 6 h CO2H + I OMe R R OMe OMe OMe OMe OMe OMe OMe OMe 89% Me OMe 62% Cl OMe OMe OMe 76% 78% Br OMe OMe 58% CF3 OMe OMe OMe 84% OMe 77% Ac OMe OMe CO2Et OMe NO2 OMe OMe 70% OMe 71% 59% Decarboxylative Heck-Type Coupling R' O OH R R' + transition-metal catalyst R Heck-Mizoroki Reaction R I R Pd catalyst + Mizoroki, T.; Mori, K.; Ozaki, A. Bull. Chem. Soc. Jpn. 1971, 44, 581. Heck, R. F.; Nolley, J. P., Jr. J. Org. Chem. 1972, 37, 2320. Review: Beletskaya, I. P.; Cheprakov, A. V. Chem. Rev. 2000, 100, 3009. Example: CO2Me Cl N OH + Pd(OAc)2 (1 mol%), Et3N, MeCN, 85°C I Cl N OH CO2Me tautomerization CO2H Cl N S OH singulair Larson, R. D. et. al. J. Org. Chem. 1996, 61, 3398. Cl N O 83% CO2Me Mechanism of the Heck Reaction of Aryl Halides base.HX Pd0L2 X base R oxidative addition L PdII X L H PdIIL2 X R ß-hydride elimination H PdIIL2X L PdII X R R X = I, Br, Cl, OTf internal rotation PdIIL2X H H R insertion Decarboxylative Heck-Type Coupling Optimized Conditions: O MeO MeO Pd(O2CCF3)2 (20 mol%), AgCO3 (3 equiv), OH + OMe (1.5 equiv) 5% DMSO-DMF, 80 °C, 1 h Notes: - 5:95 DMSO/DMF is important - DMF alone or DMSO alone gave lower yields - at least one ortho substitutent is needed Myers, A. G.; Tanaka, D.; Mannion, M. R. J. Am. Chem. Soc. 2002, 124, 11250. MeO MeO OMe 91% Scope O Pd(O2CCF3)2 (20 mol%), AgCO3 (3 equiv), R' OH + R'' R'' R' 5% DMSO-DMF, 80 - 120°C, 0.5 - 3 h R R (1.5 equiv) 42 - 99% 18 examples Scope of Aryl Carboxylic Acid: OMe Me MeO CO2H CO2H CO2H MeO OMe OMe OMe Me F F Cl CO2H F CO2H CO2H CO2H Me F F F Cl F OMe CO2H CO2H MeO OMe NO2 MeO CO2H NO2 S CO2H Me O CO2H Me Br Scope Of Alkene: CO2Et Me CO2tBu O F3C CO2H CO2H MeO N OMe Side Reactions Importance of ortho substituent O O OH + Pd(O2CCF3)2, AgCO3, 5% DMSO-DMF, 120 °C, 3 h O MeO MeO major product Importance of 5% DMSO-DMF O MeO OH + Pd(O2CCF3)2, AgCO3, 5% DMSO-DMF, 120 °C, 3 h MeO OMe OMe 71% OMe O O MeO OH + OMe Pd(O2CCF3)2, AgCO3, DMF, 120 °C, 3 h O MeO major product These side reactions probably occur by a C-H insertion or ortho-palladation reaction Arylation of 2-Cycloalken-1-ones O O OH + ( )n R R' R Pd(O2CCF3)2 (20 mol%), AgCO3 (2 equiv), 5% DMSO-DMF, 80 - 120°C, 0.5 - 3 h R R' ( )n O R (1.5 equiv) OMe Me OMe O O O Me OMe OMe Me MeO O MeO NO2 O MeO N OMe Br 89% 61% 58% 49% 63% O MeO O O MeO OMe 81% MeO OMe 65% Tanaka, D.; Myers, A. G. Org. Lett. 2004, 6, 433. MeO O MeO OMe 86% O O 64% OMe 30% Reaction of 2-Methyl-cyclopenten-1-one O OMe O OH MeO OMe OMe Pd(O2CCF3)2 (20 mol%), AgCO3 (2 equiv), O O + MeO MeO 5% DMSO-DMF, 80 - 120°C, 0.5 - 3 h OMe MeO 24% OMe O MeO OMe MeO 5% Heck Reactions of Aryl Carboxylates vs Aryl Halides O O OH MeO Pd(O2CCF3)2 (20 mol%), AgCO3 (2 equiv), 5% DMSO-DMF, 80 °C, 0.5 OMe MeO 92% O I + MeO O + OMe OMe Pd(OAc)2, NaHCO3, Bu4NCl, DMF, 80 °C, 17 h 57% O MeO OMe 7 reported reactions yields range 3% - 57% O OH ineffective in decarboxylative Heck-type coupling Me O I Pd(OAc)2, NaHCO3, Bu4NCl, DMF, 80 °C, 21 h O + Me 100% (HPLC) Me Mechanistic Studies – Insight into the Decarboxylation Step Heck Reaction with Aryl Halides – Oxidative Addition Occurs L Pd(II) L Pd(0) I oxidative addition I Heck Reaction with Aryl Carboxylic Acids – What Happens? O OH Pd(0) L Pd(II) X L Does this intermediate form. If so, how does it form and what are X and L. Tanaka, D.; Romeril, S. P.; Myers, A. G. J. Am. Chem. Soc. 2005, 127, 10323. Mechanistic Studies – Insight into the Decarboxylation Step 1H NMR Studies OMe O O O MeO OMe MeO CO2Na O CF3 MeO OMe + O Pd DMSO-d6, rt A + OMe O O F3C CF3 O O Pd OMe O O Pd O MeO (1.2 equiv) OMe OMe B OMe A:B ratio = 6:1 At 80 oC, A and B start disappearing and C forms. O OMe CF3 Pd O MeO OMe C After 15 min at 80 oC, only C is observed. Mechanistic Studies – Insight into the Decarboxylation Step 13C NMR Studies O O F3C CF3 O Pd O MeO OMe 13 OMe O (1.2 equiv) O C MeO DMSO-d6, room temperature CO2Na MeO After 8 min at 60 oC, C and 13CO2 observed O CF3 Pd O + MeO OMe C 13 CO2 O OMe O CF3 O O + Pd OMe O MeO OMe A OMe O Pd OMe OMe OMe B X-Ray of Palladium Intermediate Proposed Mechanism for the Decarboxylation Step O MeO MeO ONa OMe Pd(O2CCF3)2 DMSO-d6, 23 °C DMSO O MeO MeO DMSO O Pd O2CCF3 DMSO OMe 80 °C F3CCO2 MeO MeO Pd O MeO O OMe DMSO Pd O2CCF3 DMSO MeO OMe CO2 rate-determining step Importance of DMSO: - rate of decarboxylation is dependent on the solvent - 19:1 DMF-d7 : DMSO-d6 was 2-fold greater than DMSO-d6 alone - this is consistent with the dissociation of DMSO occurring prior to or during the rate-determining step Trifluoroacetate Plays a Key Role in the Decarboxylative Palladation - an excess of NaO2CCF3 only slightly slowed the rate of decarboxylative palladation - addition of 1.1 equiv of LiBr or nBu4NBr results in no decarboxylative palladation - Pd(OAc)2, PdCl2, PdO2, Pd(OTf)2 were ineffective - electron-donating phosphine or trialkyl amine ligands inhibit the reaction - Conclusion: electron-deficient Pd center is needed for decarboxylative palladation Final Steps: Alkene Insertion and β-Hydride Elimination NMR, X-ray, and deuterium experiments indicate the final steps are alkene insertion and β-hydride elimination (similar to Heck reactions involving aryl halide) MeO MeO DMSO Pd O2CCF3 DMSO OMe R + OMe OMe alkene insertion MeO Pd(II) ß-hydride elimination MeO R R OMe OMe H However, NMR studies indicate a reactivity pattern opposite to that of Heck reactions of aryl halides, that is: CO2tBu > CN > Competition Experiments CO2H CO2tBu CN + MeO Ph + + Pd(O2CCF3)2 (20 mol%), AgCO3, 5% DMSO-DMF, 80 °C, 24 h R MeO OMe (1 equiv) (1 equiv) OMe (1 equiv) R = CN < CO2tBu < Ph 1 : 2 : 2.7 I MeO CO2tBu CN + Ph + + R Pd(OAc)2 (10 mol%), NaHCO3, nBu4NBr, DMF, 110 °C, 30 h OMe MeO (1 equiv) (1 equiv) OMe (1 equiv) R = CN < CO2tBu < Ph 17 : 7 : 1 I + MeO CO2tBu CN Ph + + R Pd(PPh3)4 (10 mol%), Et3N, DMF, 110 °C, 30 h MeO OMe (1 equiv) (1 equiv) (1 equiv) OMe R = CN < CO2tBu < Ph 17 : 6 : 1 Conclusions: These differences are due to the electron-deficient nature of the Pd(II) species Other Interesting Transition-Metal Catalyzed Decarboxylative Couplings Pd(O2CCF3)2 (20 mol%), CF3CO2H (10 equiv), 5% DMSO-DMF, 70 °C OMe CO2H OMe H OMe R R OMe Dickstein, J. S.; Mulrooney, C. A.; O'Brien, E. M.; Morgan, B. J.; Kozlowski, M. C. Org. Lett. 2007, 9, 2441. CO2H + Ar Ar Ar [Cp*IrCl2]2 (2 mol%), Ag2CO3, o-xylene, 160 °C, 6h Ar R Ar R Ar Ueura, K.; Satoh, T.; Miura, M. J. Org. Chem. 2007 O BnS O OH Cu(2-ethylhexanoate)2 (20 mol%), wet THF, air, 23 °C O + H R MeO N N H (22 mol%) Lalic, G.; Aloise, A. D.; Shair, M. D. J. Am. Chem. 2003, 125, 2852. O BnS OH R The End I Love CO2! Albert Arnold (Al) Gore Jr. Nobel Peace Prize 2007 and future CO2 lover