ANSI standards

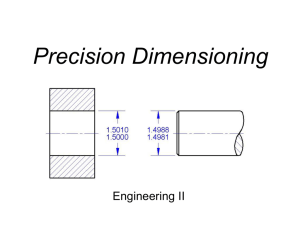

advertisement

ANSI Drafting Standards ASME Y-14.5 2009 Written by ASME or_________________________________ & Accepted by ANSI or______________________________. ANSI Standards: _______________ Projection vs. __________ Projection for ISO Two division of projection methods are __________& ____________ Drawings contain: BOM___________________ ECO____________________ ECN____________________ Zones___________________ Title Block Revision Block Balloons Notes Flag Notes Dimensions General Tolerances .x = .1 .xx = .03 .xxx = .010 Limit tolerance Unilateral tolerance Bilateral tolerance Rules to live by when Dimensioning Notate units of measure being used in title block or note (METRIC) Always dimension features of the object in most descriptive view Never dimension to hidden lines Follow dimensioning order: 1. Dimension overall sizes 2. Locate features 3. Add details for manufacturing or construction Show angles in correct sector that could actually be measured Ensure all three major dimensions are shown in one of the views o Length, Width, and Depth Follow standard practices o Placement – Not on or inside of part o Spacing – Clarity o Dimension from closest edge o Stagger and group dimension with concentric points Use Multiples (4X) for repetitive elements Use unidirectional text Leaders should theoretically pass through center of circles Use notes for drilling operations with current symbols Assume hole is through unless otherwise noted with depth symbol Always use the Ø and R for Diameter and Radius Basic dimensions- Theoretical exact size, location in box Reference dimension- information only (i.e. overall lengths) Determine best dimensioning method o Datum / Baseline o Left to Right/ bottom to top (Tape Measure Rule) o Chain line – Only hole spacing when deemed most critical (2 holes max) SF Tolerancing and Surface Texture • • • • • • Running Clearance (RC)- shaft must move freely (Inside a bearing or hole) Location Clearance Fit (LC)- Shaft and Hole may be same size (Line to Line fit) Location Interference Fits (LN)- Shaft larger than hole (Alignment dowel pins) Force and Shrink Fits (FN) - Shaft is always bigger (Transmit torque) MMC- Maximum Material Condition (Weighs most with largest shaft or smallest hole) LMC-Least Material Condition (Weighs most with smallest shaft or largest hole) GD&T Weld Notes